Linear electrode curved surface electrolysis electrical discharge machining system and method

A technology of electrolytic discharge and electrode curved surface, which is applied in the field of electric machining, can solve the problems of metamorphic layer on the surface of the workpiece, poor processing surface quality, and poor verticality of the microstructure side wall, etc., and achieve convenient large-scale, stable processing gap, and good surface. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

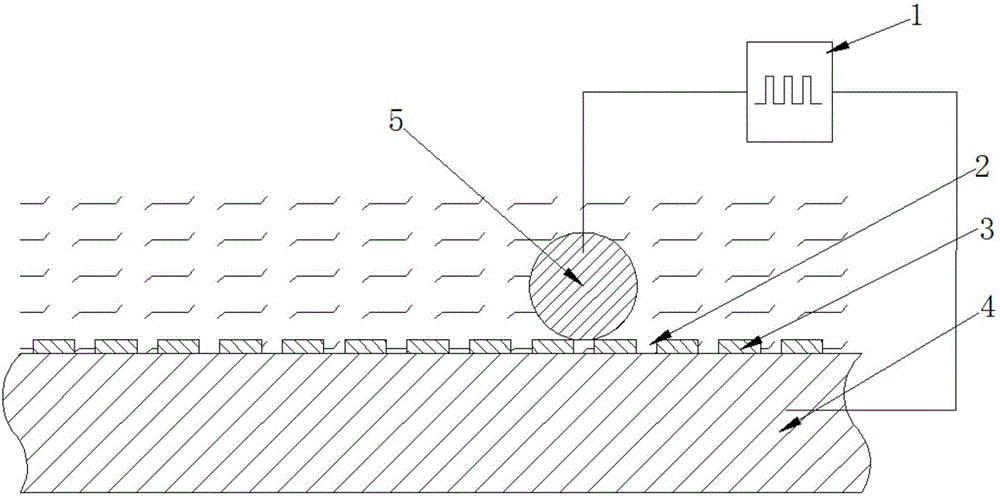

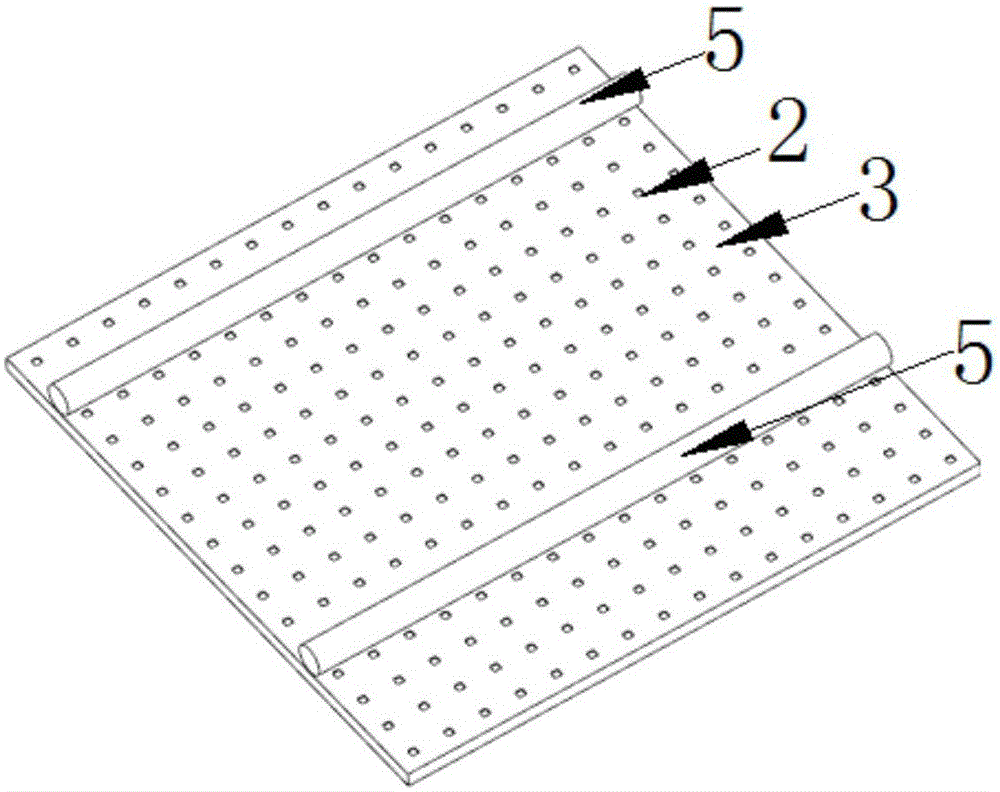

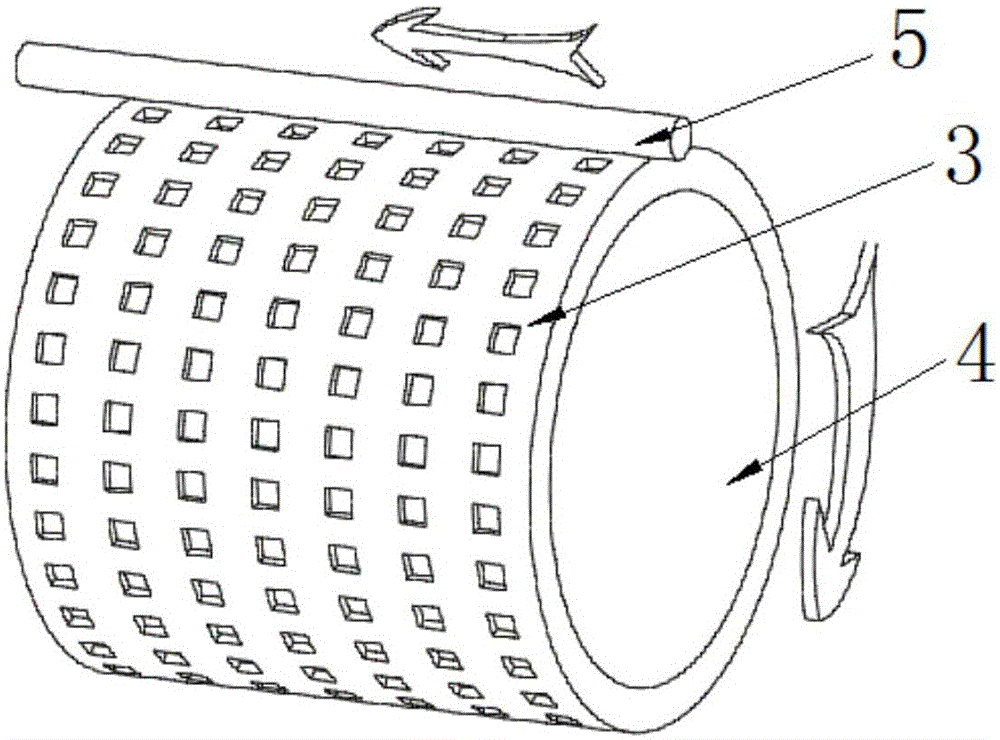

[0025] Linear electrode curved surface EDM system, such as figure 1 with figure 2 As shown, it includes a wire electrode 5 and a workpiece 4, the wire electrode 5 and the workpiece 4 are placed in the working fluid, and the wire electrode 5 is connected with the workpiece 4 and the electrode of the power source 1 to form an electric machining circuit. The processing surface of the workpiece 4 is covered with a mask 3 , and several through holes 2 are arranged on the mask 3 ; the linear electrode 5 is in contact with the mask 3 on the processing surface of the workpiece 4 . The linear electrode 5 moves against the mask 5 on the plane, not only can renew the working fluid, but also can make the machining gap very stable; the mask micro-electrolysis EDM can make the EDM only occur in the unmasked area, Improve the localization of electrical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com