Preparation method of solar reflective aluminum mirror and prepared solar reflective aluminum mirror

A solar and reflective technology, applied in the field of solar thermal utilization, can solve the problems of unfavorable recycling, bulky glass products, and difficult installation, and achieve the effect of reducing weight per unit area, cost per unit area, and installation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

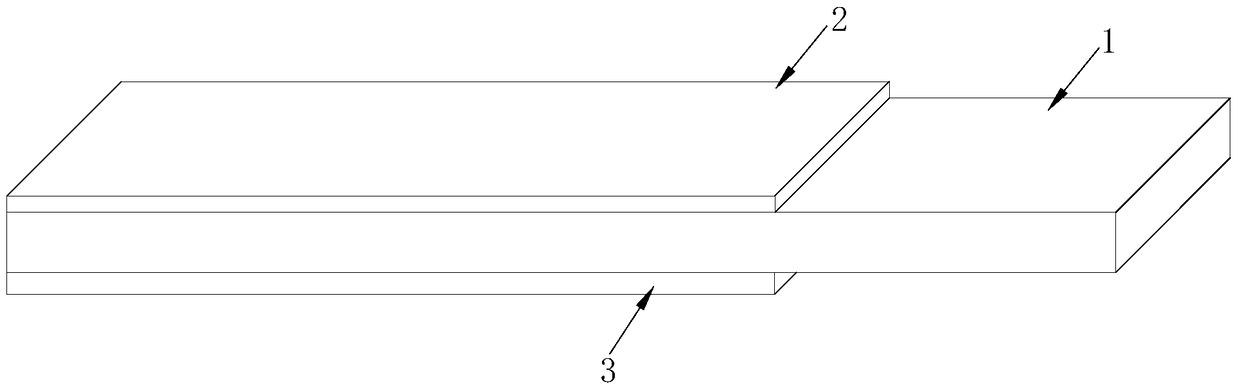

[0025] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 The structural schematic diagram of the solar reflective aluminum mirror prepared for the present invention includes an aluminum roll substrate 1 and a fluorocarbon protective layer 2 and a polyester protective layer 3 respectively arranged on the front and back sides thereof, and the preparation process includes the following steps:

[0027] a: The surface of the aluminum coil substrate is first rolled by a wet multi-pass rolling process to form a primary mirror surface, and the mirror surface degree is 80-85%;

[0028] b: Degreasing and degreasing the primary mirror surface with an alumina degreasing and degreasing agent with a free acid concentration of 17-22%, and the treatment time is 45-60 seconds;

[0029] c: Then rinse the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com