Matte BOPP film and preparation method thereof

A film and matte technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of difficult dispersion of matting materials and polypropylene, uneven matting effect on the film surface, etc., and achieve stable and uniform matting effect. The production process is easy to control and the haze distribution is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

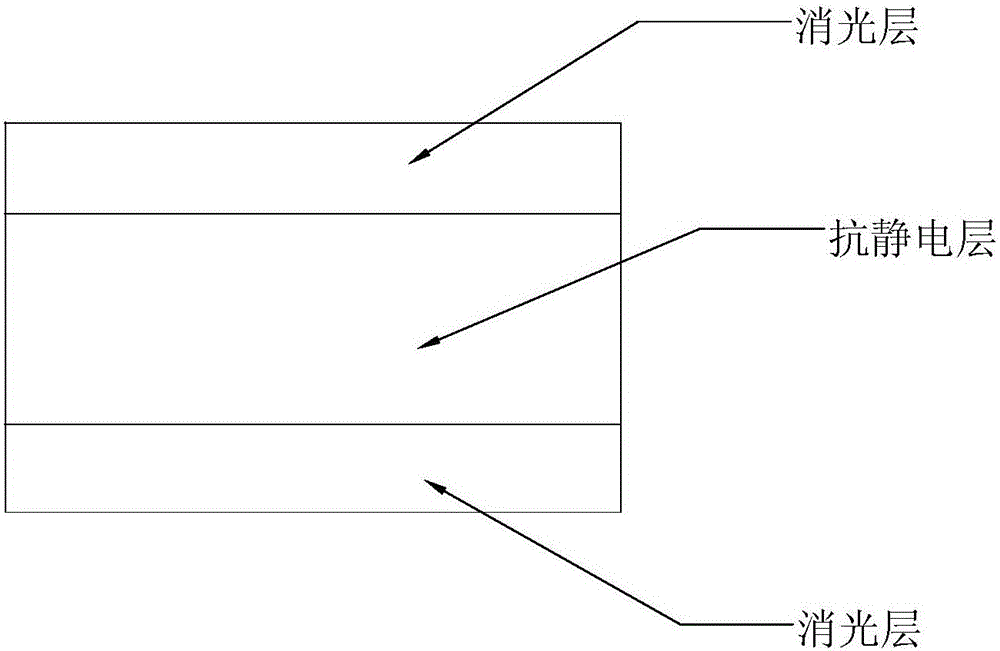

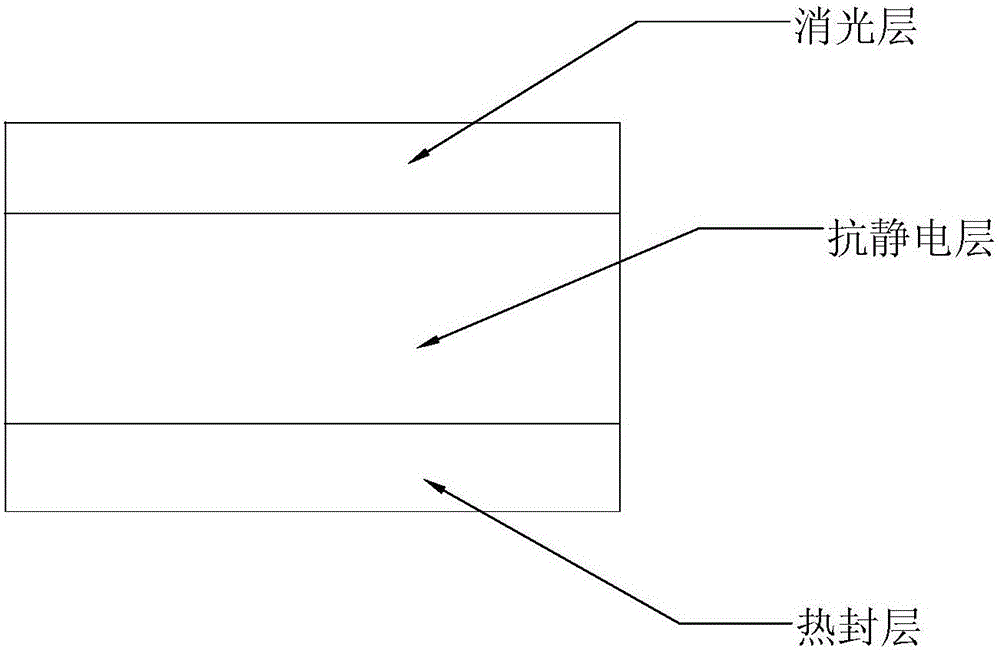

[0042] The matte BOPP film is made of the following raw materials in parts by weight: based on 1000 parts in total, homopolypropylene: 834.12 parts; polyethylene-polypropylene blend: 39.2 parts; high-density polyethylene 36.8 parts; ethylene-propylene-butene terpolymer polypropylene: 79.84 parts; antiblocking agent: 0.16 parts, antistatic agent: 5.88 parts, modified nano-silica: 2.4 parts; modified nano-titanium dioxide: 1.6 parts.

[0043] The upper surface layer is a matting layer, accounting for 80 parts in total, including 39.2 parts of polyethylene-polypropylene blend, 36.8 parts of high-density polyethylene, 2.4 parts of modified nano-silica, and 1.6 parts of modified nano-titanium dioxide.

[0044] The core layer occupies a total of 840 parts, of which 5.88 parts are antistatic agents (3.2 parts of monoglyceride and 2.68 parts of ethoxylamine), and 834.12 parts of homopolypropylene.

[0045] The lower surface layer is a heat-sealing layer, accounting for 80 parts in tot...

Embodiment 2

[0060] The matt BOPP film is made of the following raw materials in parts by weight: homopolypropylene: 805.14 parts, ethylene-propylene-butylene terpolymer polypropylene: 99.85 parts; polyethylene-polypropylene blend: 40.5 parts; Adhesive agent: 0.15 parts, antistatic agent: 4.86 parts; high-density polyethylene 45.45 parts, modified nano silicon dioxide: 3.15 parts; modified nano titanium dioxide: 0.9 parts.

[0061] The upper surface layer is a matting layer, accounting for 90 parts in total, including 40.5 parts of polyethylene-polypropylene blends, 45.45 parts of high-density polyethylene, 3.15 parts of modified nano-silica, and 0.9 parts of modified nano-titanium dioxide.

[0062] The core layer occupies a total of 810 parts, of which 4.86 parts are antistatic agents (2 parts of monoglyceride and 2.86 parts of ethoxylamine), and 805.14 parts of homopolypropylene.

[0063] The lower surface layer is a heat-sealing layer, accounting for 100 parts in total, including 99.85 ...

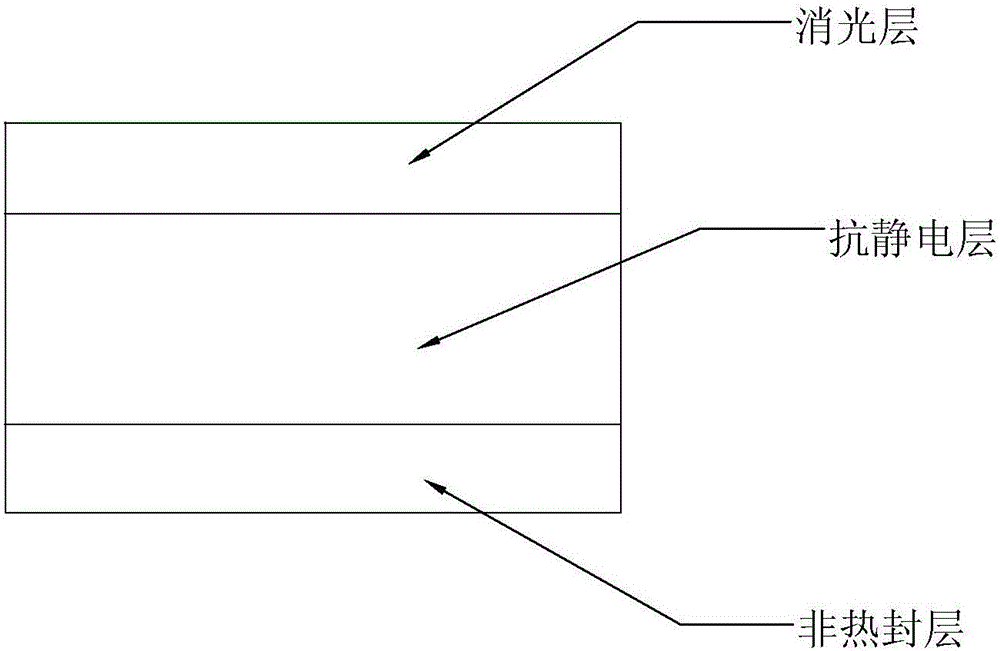

Embodiment 3

[0072] The matt BOPP film is made of the following raw materials in parts by weight: based on 1000 parts in total, homopolypropylene: 777.66 parts; polyethylene-polypropylene blend: 50 parts; high-density polyethylene 44.5 parts; ethylene-propylene-butene terpolymer polypropylene: 119.82 parts; antiblocking agent: 0.18 parts, antistatic agent: 2.34 parts, modified nano-silica: 3.5 parts; modified nano-titanium dioxide: 2 parts.

[0073] The upper surface layer is a matting layer, accounting for 100 parts in total, including 50 parts of polyethylene-polypropylene blend, 44.5 parts of high-density polyethylene, 3.5 parts of modified nano-silica, and 2 parts of modified nano-titanium dioxide.

[0074] The core layer accounts for 780 parts in total, of which antistatic agent (0.92 parts of monoglyceride and 1.42 parts of ethoxyamine) is 2.34 parts, and homopolypropylene is 777.66 parts.

[0075] The lower surface layer is a heat-sealing layer, accounting for 120 parts in total, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com