Clean production process for dye intermediate sulfonated para-ester

A technology of clean production and para-ester, which is applied in the field of clean production process of dye intermediate sulfonated para-ester, can solve the problems of inability to remove residual salt of waste acid and low adsorption efficiency, achieve mild reaction conditions and reduce waste of resources , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

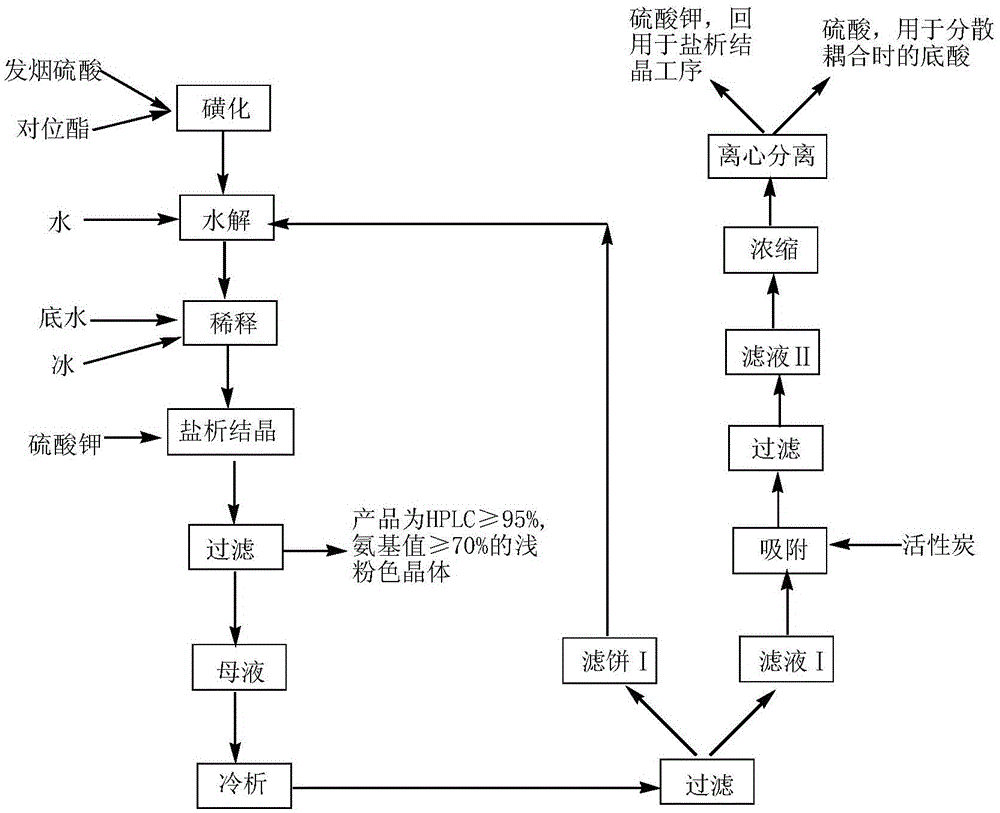

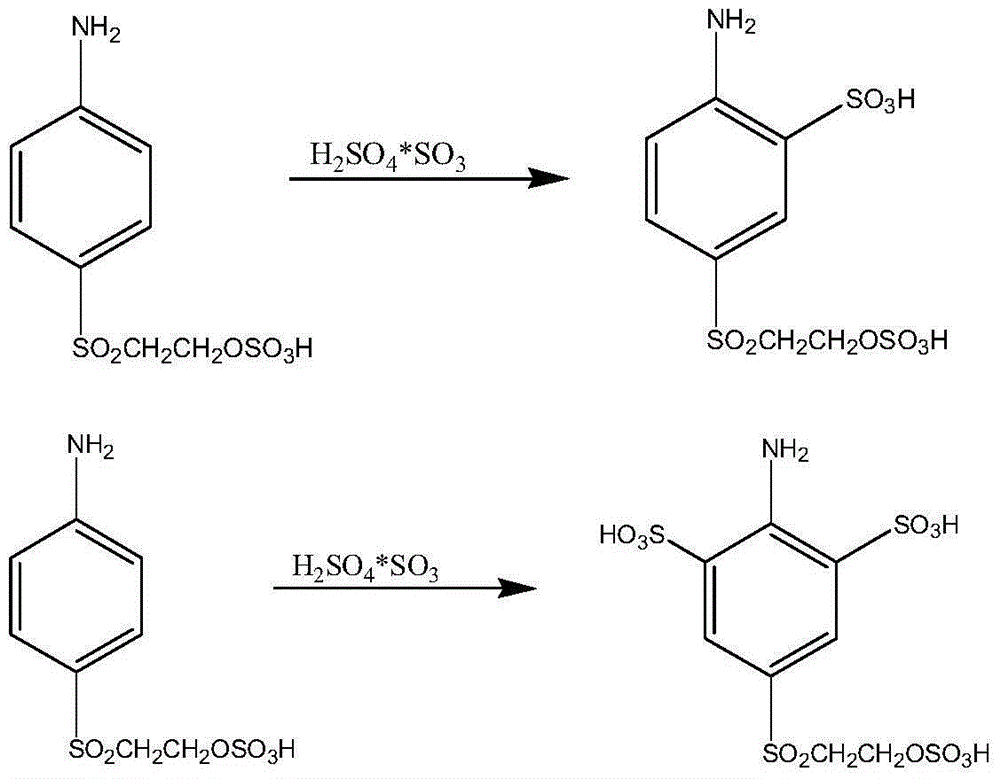

[0044] (1) Sulfonation: Add 420 g of fuming sulfuric acid to a 500 ml four-neck flask equipped with a thermometer and a stirring device, add 184 g of p-β-hydroxyethylsulfone acetanilide below 45 °C, and heat up to 133 °C in 1 hour , and insulated at 133-135°C for 4 hours.

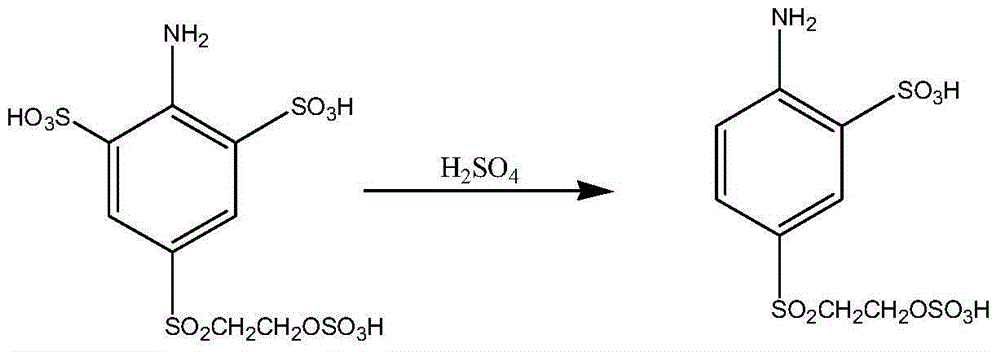

[0045] (2) Hydrolysis: cool down the sulfonated compound to 82-85°C, add 28g of water at 82-85°C, raise the temperature to 105-110°C and keep it warm for 5 hours;

[0046](3) Dilution: Cool the hydrolyzate to below 30°C, slowly put the material into a 2000ml beaker prepared with 150g of bottom water and 700g of ice for dilution, and control the dilution temperature below 25°C;

[0047] (4) Salt-out crystallization: the temperature of the diluent is controlled at 25°C, and 110 g of potassium sulfate is added to precipitate the sulfonated para-ester;

[0048] (5) Filtration: The salting-out material is filtered to obtain 212.8 g of light pink solid sulfonated para-ester, with an HPLC purity of 95.2% and an a...

Embodiment 2

[0060] Keeping other conditions unchanged in Example 1, the filter cake I obtained in the previous batch was added to step (2) for hydrolysis, and after salting out, crystallization and filtration, 219.5 g of light pink solid sulfonated para-ester was obtained, and the HPLC purity was 95.4%, the amino value is 70.7%. On the premise of product quality assurance, the yield increased by 2.9%.

Embodiment 3

[0062] (1) Sulfonation: Add 420 g of fuming sulfuric acid to a 500 ml four-necked flask equipped with a thermometer and stirring, add 184 g of p-β-hydroxyethylsulfone acetanilide below 45 ° C, and heat up to 133 ° C in 1 hour. And keep it warm at 133-135°C for 4 hours.

[0063] (2) Hydrolysis: cool down the sulfonate to 82-85°C, add 28g of water at 82-85°C, then add the filter cake I recovered in the previous batch, heat up to 105-110°C and keep it warm for 5 hours;

[0064] (3) Dilution: Cool the hydrolyzate to below 30°C, slowly put the material into a 2000ml beaker prepared with 150g of bottom water and 700g of ice for dilution, and control the dilution temperature below 25°C;

[0065] (4) Salt-out crystallization: the temperature of the diluent is controlled at 20°C, and 100 g of potassium sulfate is added to precipitate the sulfonated para-ester;

[0066] (5) Filtration: the salting-out material is filtered to obtain 220.1 g of light pink solid sulfonated para-ester, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com