Preparation method of oxidizing-type coenzyme I

An oxidized coenzyme and yeast cell technology, which is applied in chemical instruments and methods, preparation of sugar derivatives, organic chemistry, etc., can solve the problems that cannot meet the needs of industrialized large-scale production, is not suitable for industrialized large-scale production, and has unsatisfactory results. No toxic chemical residues, mild conditions, and less destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

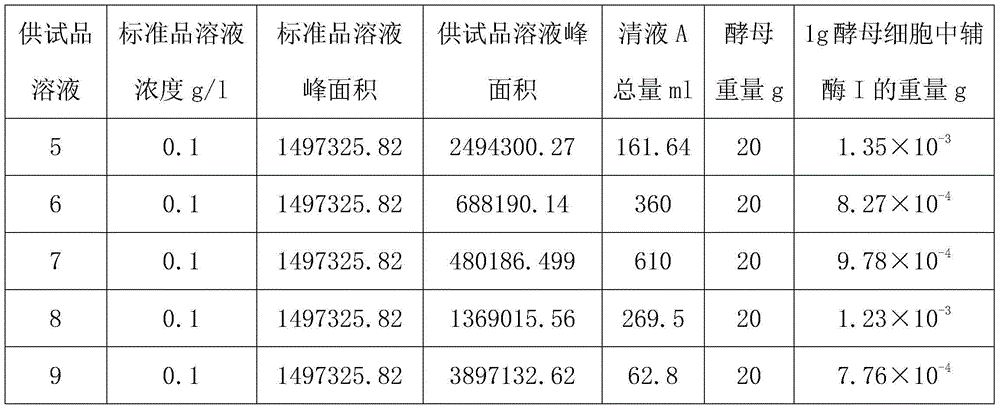

Embodiment 1

[0030] A preparation method of oxidized coenzyme I, comprising the steps of breaking yeast cells and extracting NAD + ;

[0031] Among them, the specific steps of breaking the yeast cells are: add the yeast cells into hydrochloric acid with a concentration of 0.01mol / l and soak for 2.5 hours, heat to 85°C, keep warm for 8min, add ice cubes and cool to room temperature at a speed of 10°C / min, Centrifuge at a speed of 4000rpm for 20min to obtain supernatant A; stir for 16h, add 717 # Resin, after stirring, filter to obtain supernatant B, wherein the weight volume ratio (g / ml) of yeast cells and hydrochloric acid is 15:400, yeast cells and 717 # The weight ratio of the resin is 15:45;

[0032] Among them, the extraction of NAD + The specific steps are as follows:

[0033] S1. Acidification: adding hydrochloric acid with a concentration of 5 mol / l to the clear liquid B to adjust the pH to 2.05 to obtain a solution C;

[0034] S2. Exchange: Put the solution C obtained in S1 on...

Embodiment 2

[0041] A preparation method of oxidized coenzyme I, comprising the steps of breaking yeast cells and extracting NAD + ;

[0042] Among them, the specific steps of breaking the yeast cells are: adding the yeast cells into hydrochloric acid with a concentration of 0.12mol / l and soaking them for 0.5h, heating to 100°C, keeping the temperature for 3min, adding ice cubes and cooling to room temperature at a speed of 15°C / min, Centrifuge at a speed of 6000rpm for 10min to obtain supernatant A; stir for 12h, add 717 # Resin, filtered after stirring to obtain supernatant B, wherein the weight volume ratio (g / ml) of yeast cells and hydrochloric acid is 25:80, yeast cells and 717 # The weight ratio of the resin is 25:90;

[0043] Among them, the extraction of NAD + The specific steps are as follows:

[0044] S1. Acidification: add hydrochloric acid with a concentration of 7 mol / l to the clear liquid B to adjust the pH to 1.95 to obtain a solution C;

[0045] S2. Exchange: Put the s...

Embodiment 3

[0052] A preparation method of oxidized coenzyme I, comprising the steps of breaking yeast cells and extracting NAD + ;

[0053] Among them, the specific steps of breaking the yeast cells are: add the yeast cells into hydrochloric acid with a concentration of 0.11mol / l and soak them for 0.7h, heat them to 98°C, keep them warm for 7min, add ice cubes and cool them down to room temperature at a speed of 12°C / min, Centrifuge at a speed of 5500rpm for 18min to obtain supernatant A; stir for 13h, add 717 # Resin, after stirring, filter to obtain supernatant B, wherein the weight volume ratio (g / ml) of yeast cells and hydrochloric acid is 22:100, yeast cells and 717 # The weight ratio of the resin is 22:70;

[0054] Among them, the extraction of NAD + The specific steps are as follows:

[0055] S1. Acidification: add hydrochloric acid with a concentration of 6.5 mol / l to the clear liquid B to adjust the pH to 1.98 to obtain a solution C;

[0056] S2. Exchange: Put the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com