Aminated zinc oxide nano wire-carbon fiber hybrid reinforcement and preparation method thereof

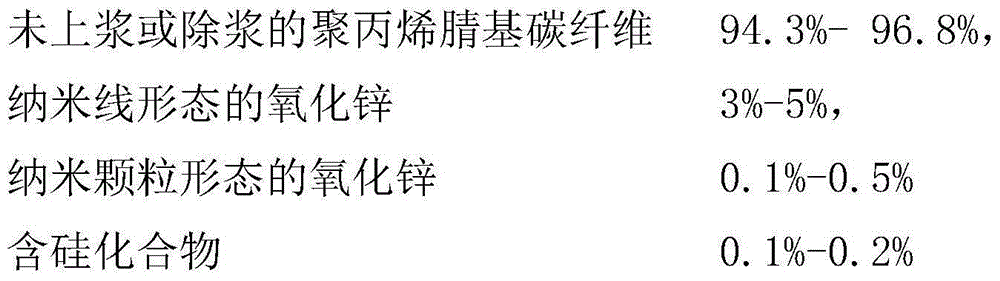

A technology of zinc oxide nanowires and polyacrylonitrile-based carbon fibers, which is applied in the direction of gaseous chemical plating, superimposed layer plating, coating, etc., can solve the problem of low interface strength retention, failure to meet the requirements of wet heat performance, and dissipation and other problems, to achieve the effect of high particle size distribution uniformity and high-quality zinc oxide nanowire array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

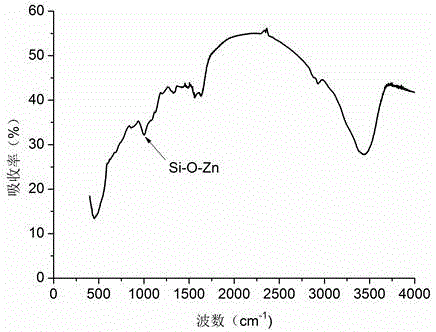

Method used

Image

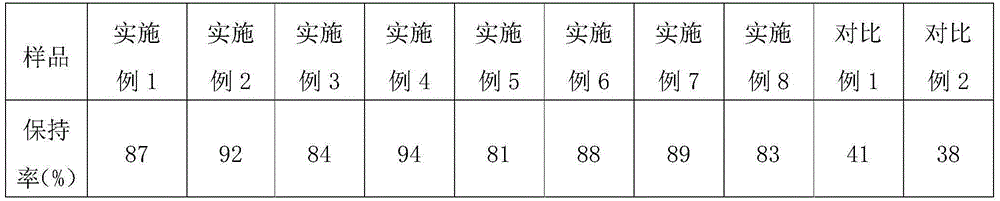

Examples

Embodiment 1

[0023] Take a section of 10 cm long unsized T700 grade polyacrylonitrile-based carbon fiber (produced by the Shanxi Institute of Coal Chemistry, Chinese Academy of Sciences) obtained by the dry spray wet spinning process, with dimethyl zinc as the zinc source and deionized water as the oxygen source , control the temperature of the zinc source to -25°C, the temperature of the oxygen source to 3°C, and at the operating temperature of 230°C, control the deposition time to be 10 minutes, and use atomic layer deposition equipment to prepare zinc oxide nano-layers on the surface of the carbon fiber. With the carbon fiber as the anode, the gold wire with a diameter of 60 microns as the cathode, and the silver-silver chloride electrode as the reference electrode, the three are placed in a reaction solution containing zinc nitrate with a concentration of 1.5 moles per liter , and hexamethylenetetramine with a concentration of 1.5 moles per liter, the temperature of the reaction solutio...

Embodiment 2

[0026]Take a 10 cm long T700S carbon fiber from Toray Corporation of Japan, remove the carbon fiber surface sizing agent according to the method described in Appendix A of GJB1982-94, and then vacuum dry the carbon fiber at 60°C for 48 hours. Diethyl zinc is used as the zinc source, hydrogen peroxide with a mass fraction of 20% is used as the oxygen source, the temperature of the zinc source is controlled at -23°C, the temperature of the oxygen source is 5°C, and the operating temperature is 240°C, and the deposition time is controlled to be 20 Minutes, using atomic layer deposition equipment to prepare a zinc oxide nano-layer on the surface of the carbon fiber. With the carbon fiber as the anode, the gold wire with a diameter of 50 microns as the cathode, and the silver-silver chloride electrode as the reference electrode, the three are placed in a reaction solution containing a concentration of 2 moles per liter of zinc acetate , and ammonia water with a concentration of 2 m...

Embodiment 3

[0029] Take a section of 10 cm long unsized T700 grade polyacrylonitrile-based carbon fiber (produced by the Shanxi Institute of Coal Chemistry, Chinese Academy of Sciences) obtained by the dry spray wet spinning process, with dimethyl zinc as the zinc source and deionized water as the oxygen source , control the temperature of the zinc source to -24°C, the temperature of the oxygen source to 4°C, and at an operating temperature of 232°C, control the deposition time to 12 minutes, and prepare a zinc oxide nano-layer on the surface of the carbon fiber by atomic layer deposition equipment. With the carbon fiber as the anode, the gold wire with a diameter of 50 microns as the cathode, and the silver-silver chloride electrode as the reference electrode, the three are placed in a reaction solution containing zinc nitrate with a concentration of 1.6 moles per liter , and hexamethylenetetramine with a concentration of 1.8 moles per liter, the temperature of the reaction solution was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com