Polyurethane adhesive containing epoxy-terminated polyether and preparation method

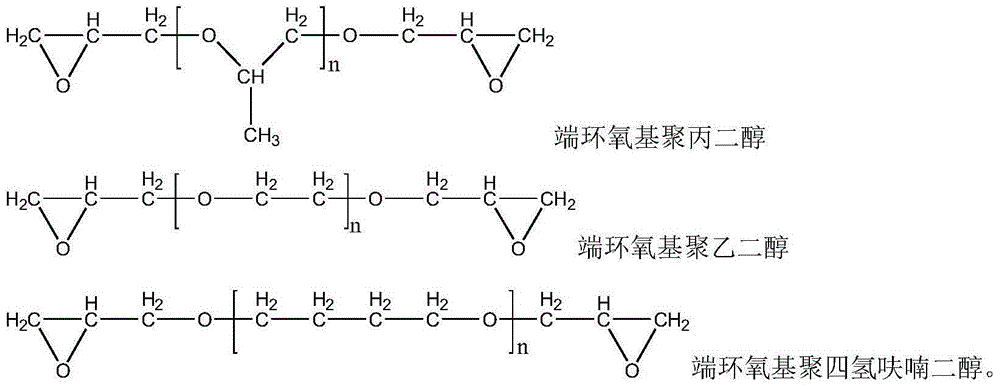

A technology of epoxy-terminated polyether and polyurethane adhesives, which is applied in the direction of polyurea/polyurethane adhesives, polyether adhesives, adhesives, etc., and can solve problems affecting bonding performance, poor temperature resistance, delamination, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

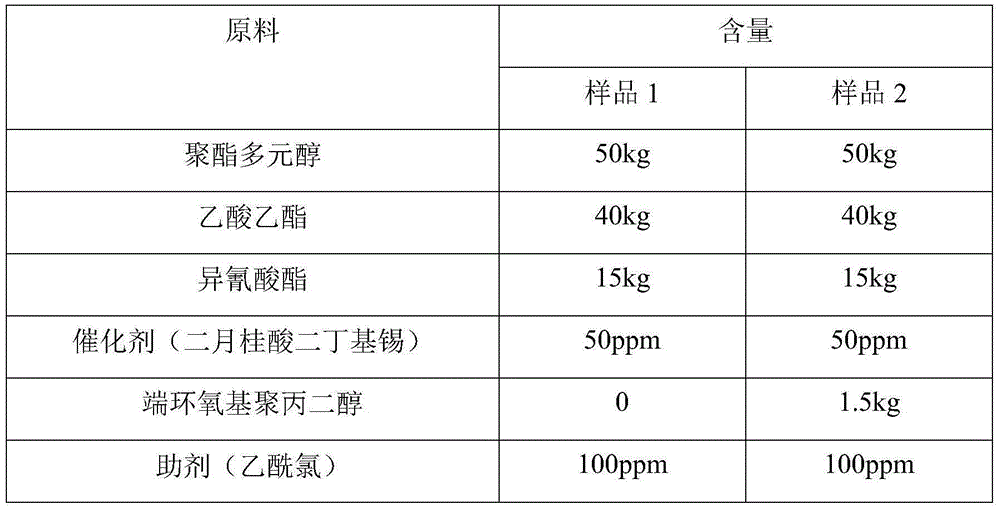

[0019] Polyurethane adhesive component A was synthesized according to the raw material formula shown in Table 1, wherein no epoxy-terminated polyether was added to sample 1, and epoxy-terminated polypropylene glycol was added to sample 2.

[0020] Table 1. Polyurethane Adhesive A Component Formula

[0021]

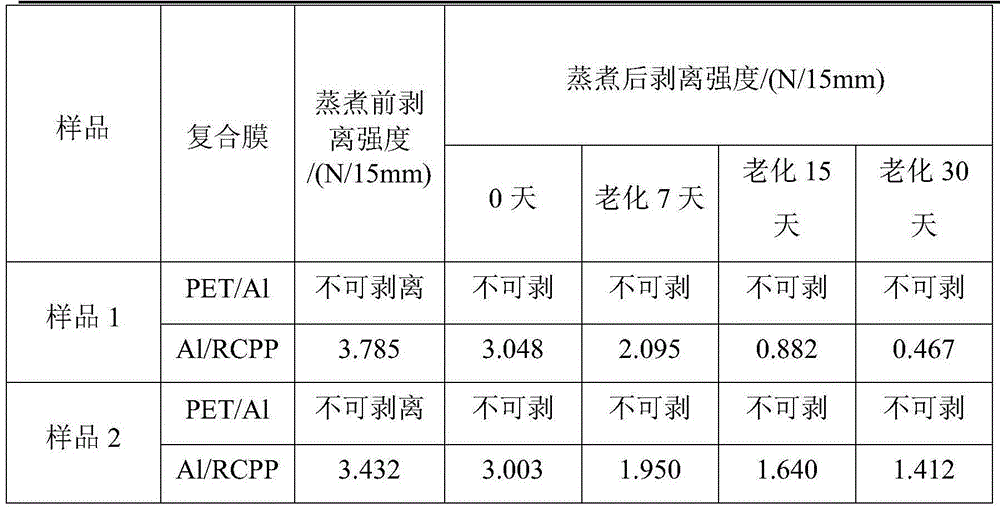

[0022] The compounded component A and component B (polyurethane prepolymer, provided by Guangzhou King Fine Chemical Co., Ltd.) were used to mix and compound the glue, and the compounded glue was used for mechanical compounding. The compound film structure was PET / Al / RCPP. Matured in an oven at 50°C for 72 hours. After the curing was completed, the films of sample 1 and sample 2 were taken to make packaging bags. At least 2 bags were made for each group. The content was infinite spicy chicken wings produced in Guangdong, with a total mass of 30g. Cook at 125°C for 45 minutes. After cooking, take one kind of packaging bag to test the peel strength. At the same time, put ...

Embodiment 2

[0026] Component A of the polyurethane adhesive was synthesized according to the raw material formula shown in Table 3, and epoxy-terminated polyethylene glycol was added to sample 3.

[0027] Table 3. Polyurethane Adhesive A Component Formulation

[0028]

[0029] The specific implementation method is the same as in Example 1, and the peel strength test results are shown in Table 4.

[0030] Table 4. Peel Strength Test Results

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com