Polyamide composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of not too high rejection rate, low water flux, low rejection rate, etc., and achieve improvement The effect of interception rate, short process flow and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

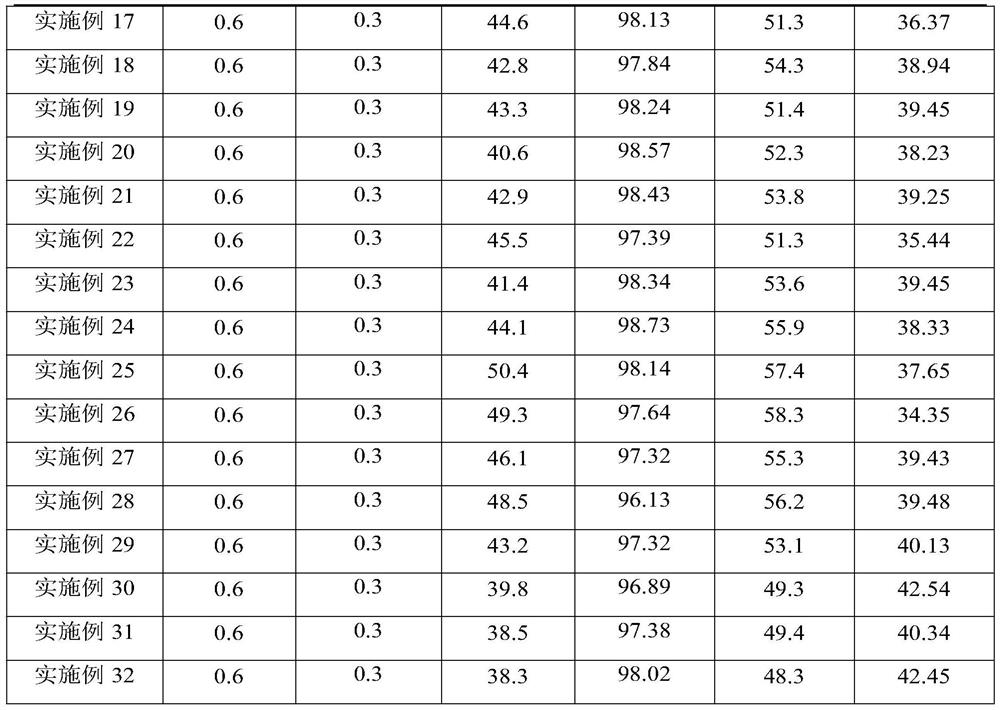

Examples

Embodiment 1

[0030] A polyamide composite nanofiltration membrane, comprising a support base layer and a polyamide functional layer obtained by interfacial polymerization on the support base layer, the polyamide functional layer comprising the following raw material components: diamine, inorganic salt, organic acid , polyacyl chloride, oil phase solvent and deionized water, the diamine is piperazine, and the polyacyl chloride is trimesoyl chloride.

[0031] The inorganic salt is lithium chloride.

[0032] The organic acid is citric acid.

[0033] The oil phase solvent is n-hexane.

[0034] The support base layer is a polysulfone porous support layer, and the specific preparation process is as follows: Weigh 75g of polysulfone resin (PSF), 375g of N-methylpyrrolidone (NMP), 50g of polyethylene glycol 200 (PEG200), and mix and prepare 500g solution, and stirred at 70°C for 6h to prepare a uniformly dispersed casting solution. After the casting solution is filtered and vacuum degassed, it ...

Embodiment 2

[0046] The difference from Example 1 is that the mass percentage of lithium chloride is 0.6 wt%.

Embodiment 3

[0048] The difference from Example 1 is that the mass percentage of lithium chloride is 1 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com