Fracturing fluid prepared by utilizing fracturing flow-back fluid and preparation method thereof

A fracturing flowback fluid and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large dosage of chemicals, system paralysis, inconvenient operation, etc., to achieve recycling, good portability, etc. Sand performance, the effect of saving water for dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

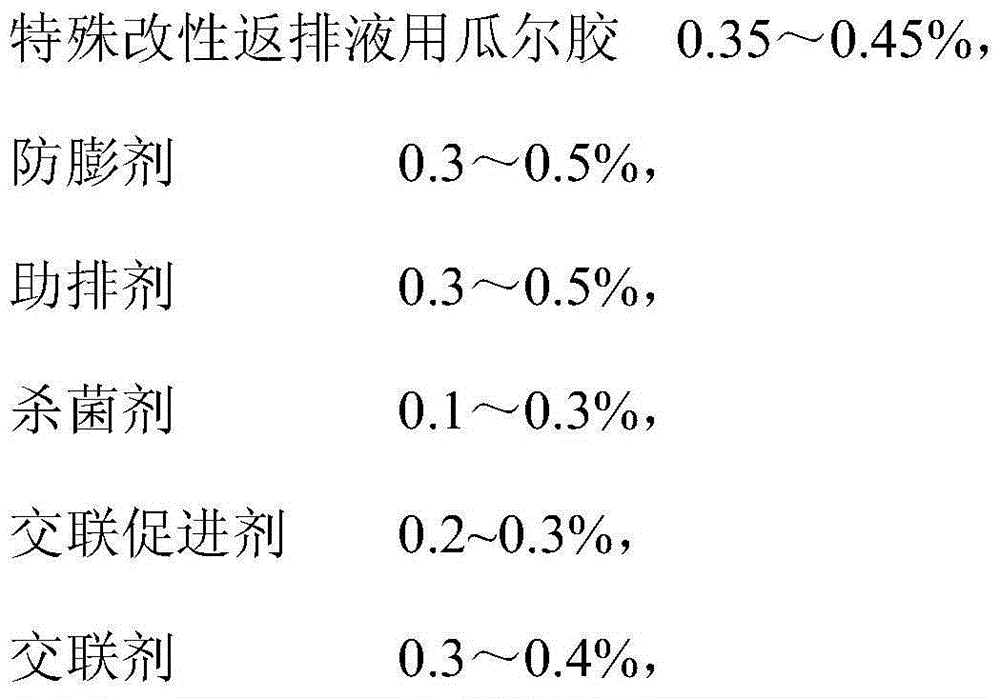

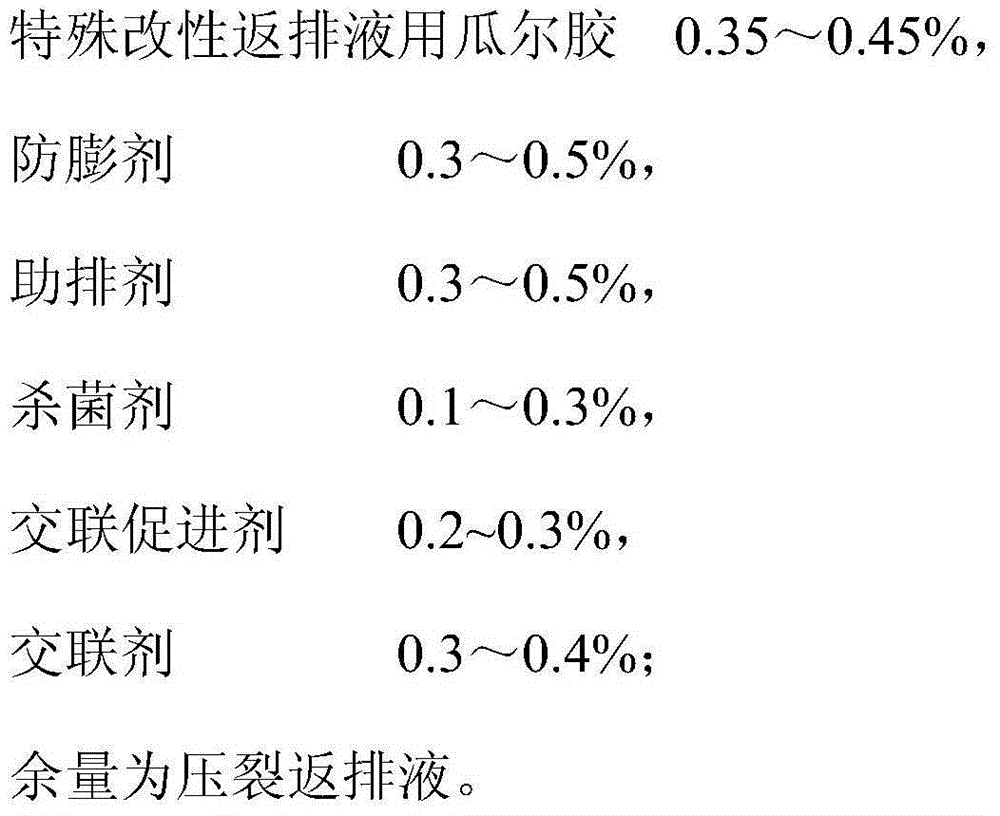

[0020] Take 1000ml of fracturing flowback fluid, and simply filter the flowback fluid to remove mechanical impurities such as proppant and some large pieces of jelly in the flowback fluid; then pour the flowback fluid into the Wu Yin mixer cup During the stirring process, add 4.0g of guar gum for specially modified flowback fluid to the fracturing flowback fluid, the degree of substitution of the guar gum is 400% higher than the conventional degree of substitution of instant guar gum; after stirring for 5 minutes, add 3.0 g of guar gum g anti-swelling agent, 3.0g drainage aid, 1.0g bactericide, stir evenly to obtain the base liquid, let it stand for 30min; add 2.5g of cross-linking accelerator and 3.0g of cross-linking agent to the base liquid while stirring, The gel fracturing fluid is formed, and the crosslinking time is 2 minutes; the temperature resistance and shear resistance of the gel are measured by RS6000 rheometer, at 120°C, 170s -1 Under the condition of cutting 2h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com