Comprehensive utilization method of aluminum electrolytic waste cathode materials

A cathode material, aluminum electrolysis technology, applied in the fields of metallurgy and environmental protection, can solve the problems of unsatisfactory separation effect, insufficient carbonaceous material and electrolyte purity, no secondary pollution, obvious economic and social benefits, and simple and easy process row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Application of electrolytic aluminum production plant with annual production capacity of 200,000 tons

[0045] (1) Basic situation:

[0046] The electrolytic aluminum plant with an annual production capacity of 200,000 tons adopts 300kA large-scale pre-baked cell electrolysis technology and pre-baked anode baking technology. Annual waste cathode production is 8,000 tons. The reference cathode composition is as follows: the carbon content is 33-65% (wherein, the graphitization degree of the cathode residue carbon is as high as 70-88%); the electrolyte composition content is 65-32%.

[0047] (2) Application method

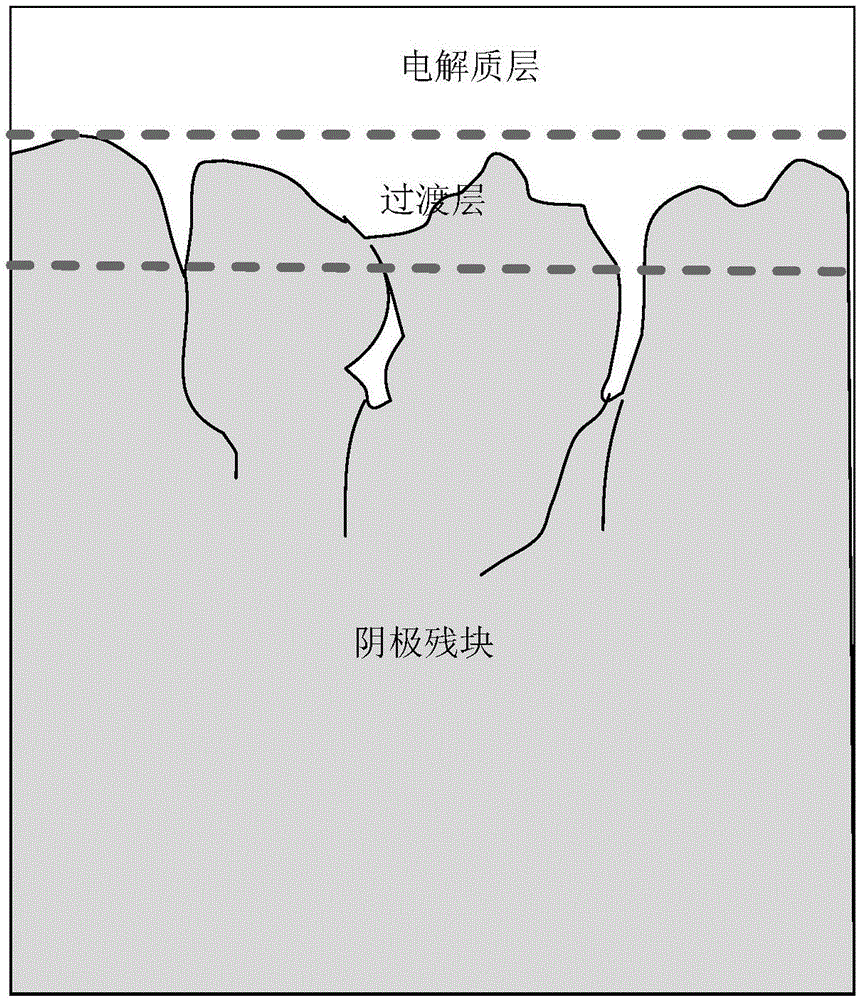

[0048] In the process of dismantling the electrolytic cell, first clean up the electrolyte layer at the bottom of the electrolytic cell. You can see about 50mm below the carbon cathode material. The transition layer of electrolyte and cathode material is transported to the sorting workshop, and the cathode is removed. The debris is transported to the pro...

Embodiment 2

[0053] Example 2: Application of electrolytic aluminum enterprises with an annual output of 600,000 tons

[0054] (1) Basic situation

[0055] The electrolytic aluminum plant with an annual production capacity of 600,000 tons adopts 300kA large-scale pre-baked cell electrolysis technology and pre-baked anode baking technology. The annual waste cathode production is 20000-24000 tons. The reference cathode composition is as follows: the carbon content is 42-69%, the graphitization degree of the cathode residue is as high as 70-88%; the electrolyte composition content is 58-31%.

[0056] (2) Application method

[0057] In the process of dismantling the electrolytic cell, first clean up the electrolyte layer at the bottom of the waste cell. You can see about 50mm below the carbon cathode material. The transition layer of electrolyte and cathode material is transported to the sorting workshop to remove the cathode residue. The blocks are transported to the processing workshop. Manual s...

Embodiment 3

[0062] Example 3: Application in an industrial park with an annual output of 1 million tons of electrolytic aluminum

[0063] (1) Basic situation

[0064] The aluminum industry park has an annual electrolytic aluminum production capacity of 1 million tons. Using 200-350kA large-scale pre-baked cell electrolysis technology and pre-baked anode baking technology. The annual production of waste cathodes is 38,000-46,000 tons. The composition of the reference cathode residue is as follows: the carbon content is 38-67%, the graphitization degree is as high as 70-88%; the electrolyte component content is 62-33%.

[0065] (2) Application method

[0066] In the process of dismantling the electrolytic cell, first clean up the electrolyte layer at the bottom of the waste cell. You can see about 50mm below the carbon cathode material. The transition layer of electrolyte and cathode material is transported to the sorting workshop to remove the cathode residue. The blocks are transported to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com