Continuous production and sintering device for self-supported ceramic thin film

A technology of ceramic film and sintering device, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., can solve the problems of short uniform temperature zone, low degree of automation, and inability to realize continuous production and sintering, so as to ensure vacuum degree and realize The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following embodiments will describe the structure and working principle of the present invention in detail with reference to the accompanying drawings.

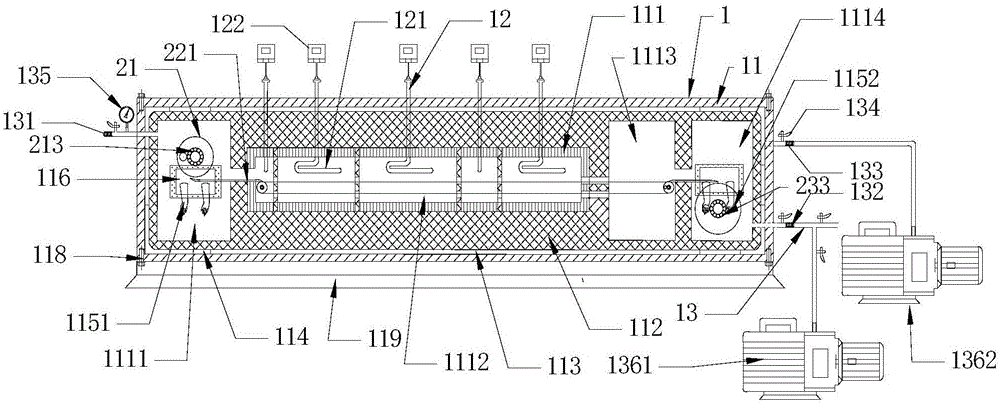

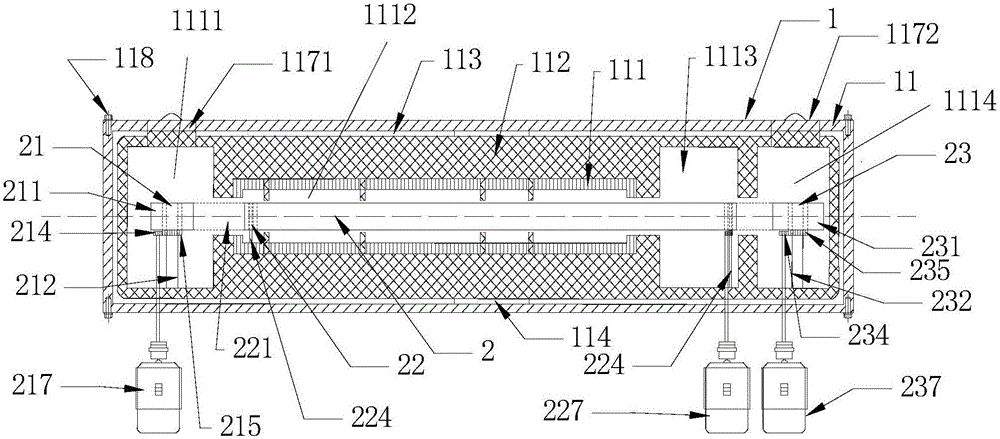

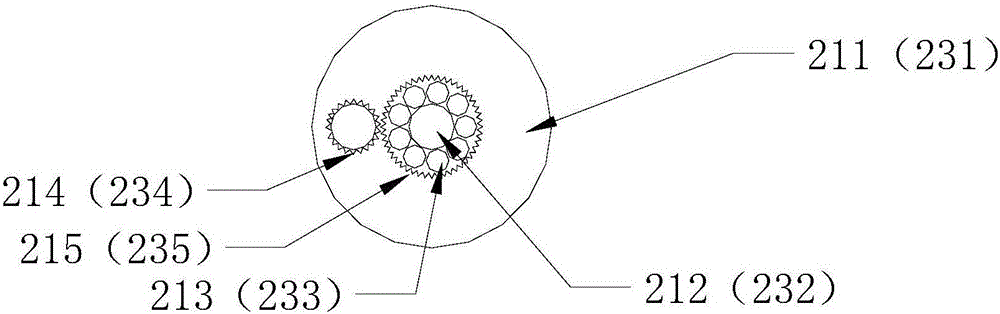

[0039] see Figure 1~4 , the embodiment of the present invention is provided with a high temperature furnace system 1 and a sample transfer system 2 .

[0040] The high temperature furnace system 1 is provided with a furnace body 11 , a heating device 12 and a vacuum device 13 .

[0041] The body of furnace 11 is a double-layer structure of an inner furnace and an outer furnace. The body of furnace 11 is provided with a hearth 111, an insulating layer 112 and a vacuum layer 113. The hearth 111 is divided into a sampling chamber 1111, a sintering chamber 1112, and a sintering chamber 1112 by the insulating layer 112. Cooling chamber 1113, sampling chamber 1114, vacuum layer 113 is set between the inner furnace body and the outer furnace body, sampling chamber 1111 is provided with sampling chamber glove box 1151, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com