Method for detecting diffusion coefficient of water vapor in bituminous mixture

A technology of asphalt mixture and diffusion coefficient, which is applied in measuring devices, analytical materials, instruments, etc., can solve the problem of time-consuming, and achieve the effect of reducing interference, saving test time, and speeding up test progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

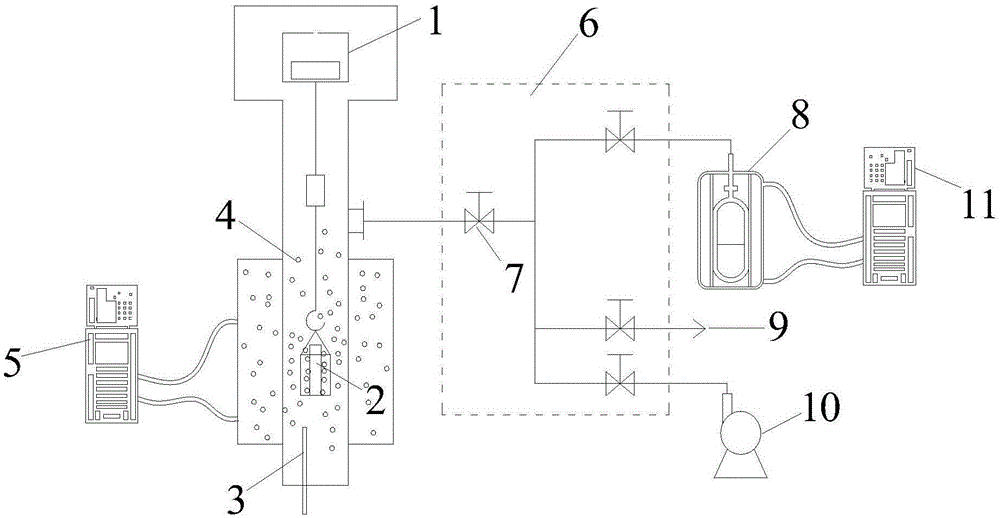

[0025] Asphalt mixture water vapor diffusion coefficient detection device of the present invention, refer to the attached figure 1 shown. Including magnetic levitation balance 1, sample barrel 2, constant temperature circulation bath (5, 11), vacuum pump 10, reagent vial 8; Magnetic levitation balance 1 and sample barrel 2 are placed in the airtight cavity, and described airtight cavity passes constant temperature circulation bath 5 and temperature The probe 3 controls the temperature of the airtight chamber, and the airtight chamber also controls the degree of vacuum therein through the vacuum pump 10; the gas control valve 9 is used for the internal back pressure of the airtight chamber; the reagent vial 8 is used for storing distilled water, and is The control valve 7 quantitatively inputs water va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com