A high-power dual-rotation brushless DC motor control system for underwater vehicles

A technology of brushed DC motors and underwater vehicles, which is applied in the field of high-power double-rotation brushless DC motor control systems for underwater vehicles, and can solve the problem of large rated torque, high rated speed, increased motor commutation control torque suppression and the difficulty of current detection and overcurrent protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

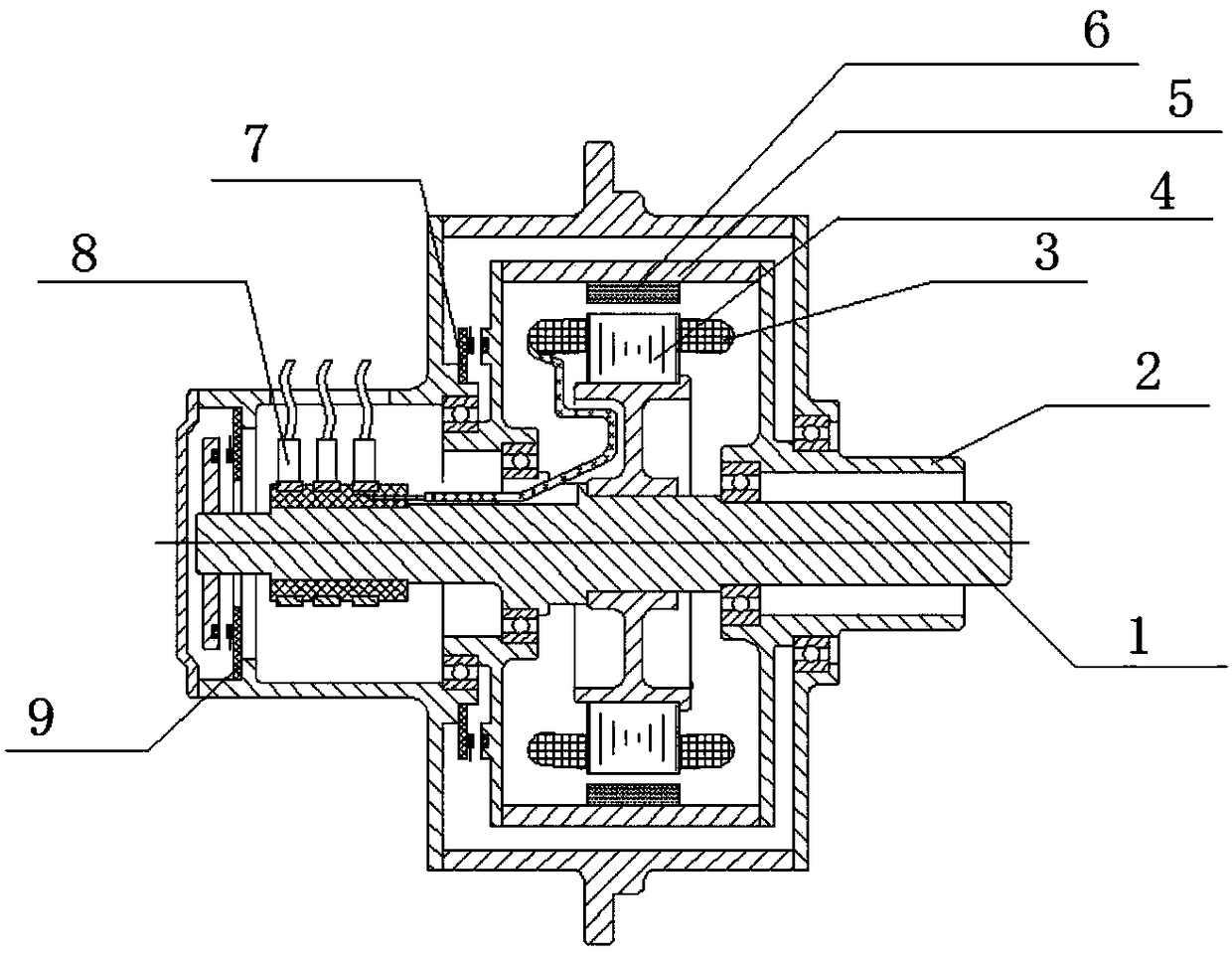

[0036] Refer to attached image 3 , The double-rotation brushless DC motor is composed of an inner rotor, an outer rotor, an inner rotor Hall disc, an outer rotor Hall disc, an inner shaft, an outer shaft, and a slip ring.

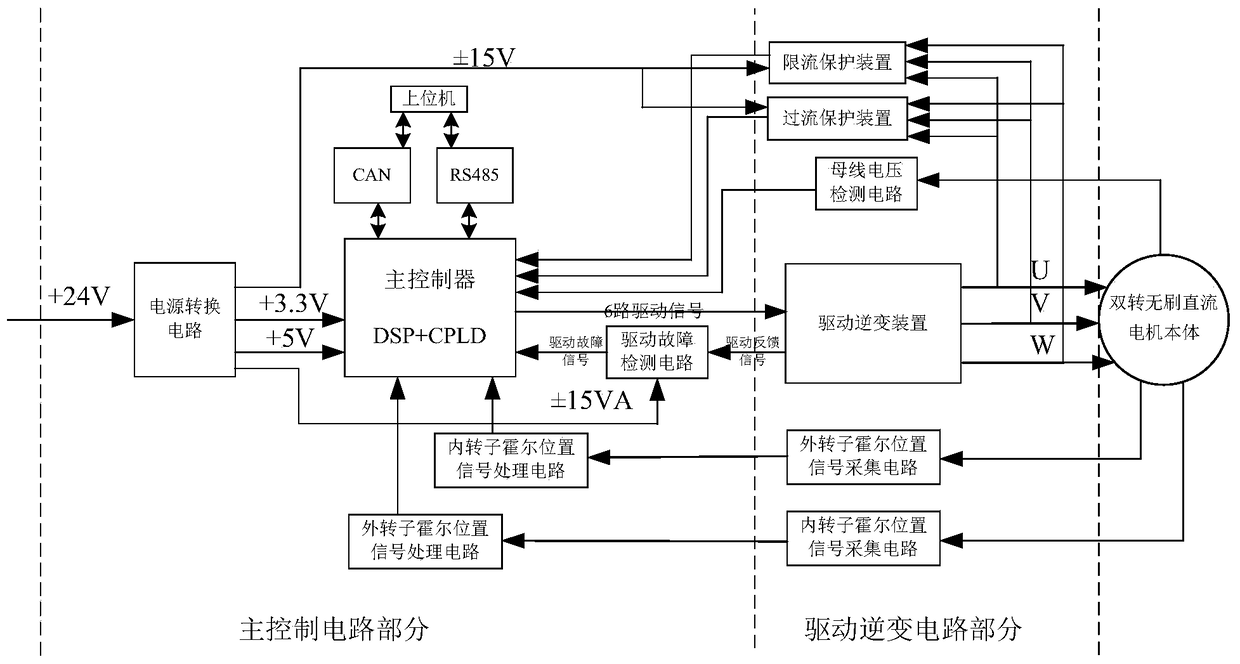

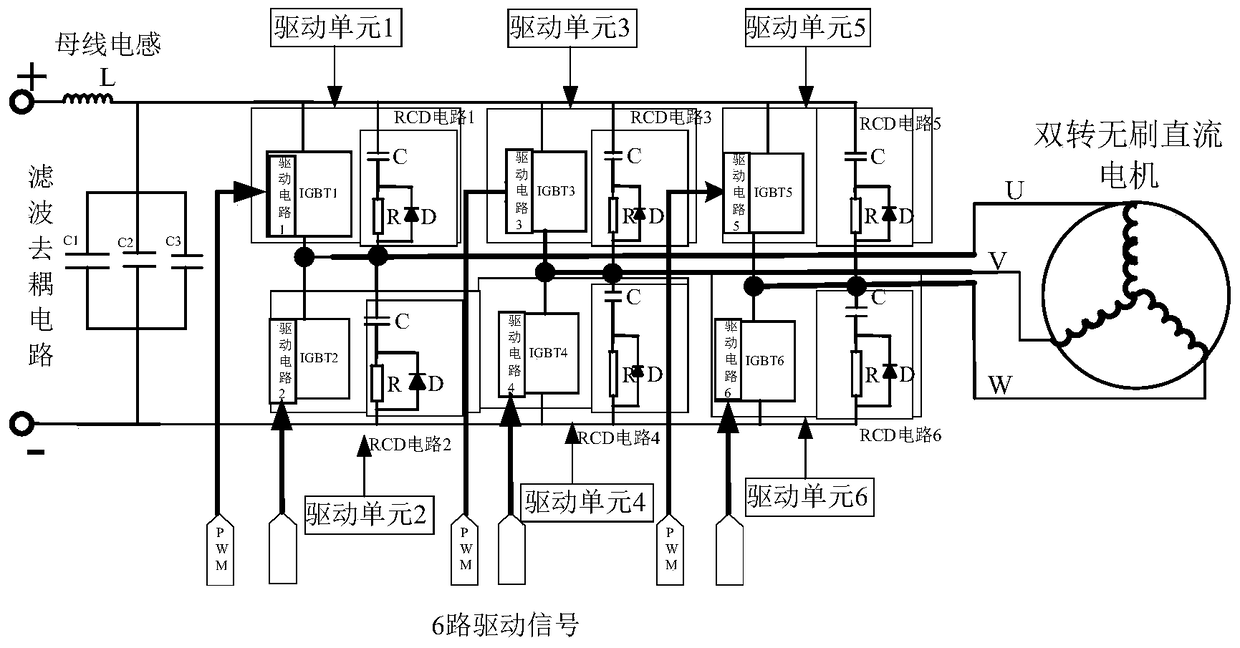

[0037] Refer to attached figure 1 A high-power double-rotation brushless DC motor control system for underwater vehicles, including a power conversion circuit, a CAN communication circuit, an RS485 communication circuit, an inner rotor Hall position signal acquisition circuit, an outer rotor Hall position signal acquisition circuit, an inner The rotor Hall position signal processing circuit, the outer rotor Hall position signal processing circuit, the main controller, the drive fault detection circuit, the drive inverter device, the overcurrent protection device, the current limiting protection device and the bus voltage detection circuit; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com