Flotation machine with integrated bolts and cover board

A technology of integrated cover plate and flotation machine, which is applied in the field of flotation machine, which can solve the mismatch between the service life of the conical lag bolt and the cover plate, the fast wear speed of the conical lag bolt of the cover plate, and the easy production of eddy current in the pulp, etc. problems, to achieve the effect of slow wear, smooth surface and smooth slurry flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

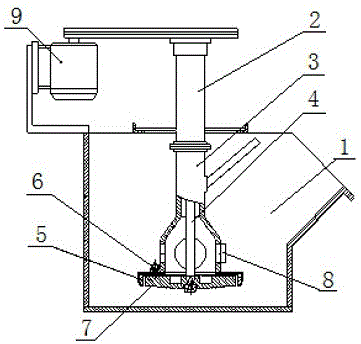

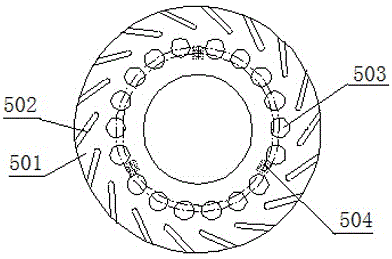

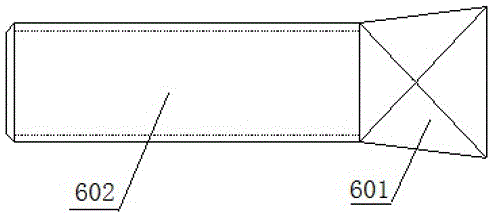

[0023] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the bolt-cover integrated flotation machine of the present invention includes a tank body 1, a bearing body 2, an air cylinder 3, a main shaft 4, a cover plate 5, a tapered lag bolt 6, and an impeller 7; The head bolt 6 includes a tapered square head 601 and a screw rod 602; the bearing body 2 is installed above the tank body 1 with angle steel, the lower end of the bearing body 2 is connected with the upper end of the air cylinder 3 through a flange, and the lower end of the air cylinder 3 is arranged There are three ear holes that match the size of the tapered square head 601, and multiple ear holes can be set as needed to achieve a more stable fixation effect. The tapered lag bolt 6 fixes the air cylinder 3 with the cover plate 5 through the ear hole; the main shaft 4 is installed in the bearing body 2 and the air cylinder 3, and the lower end of the main shaft 4 passes through the cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com