Large-size axial ultrasound-assisted end face grinding abrasive disk

An ultrasonic-assisted, end-face grinding technology, applied in the field of grinding disc devices, can solve problems such as difficult to achieve large-size grinding discs or ultrasonic vibration of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

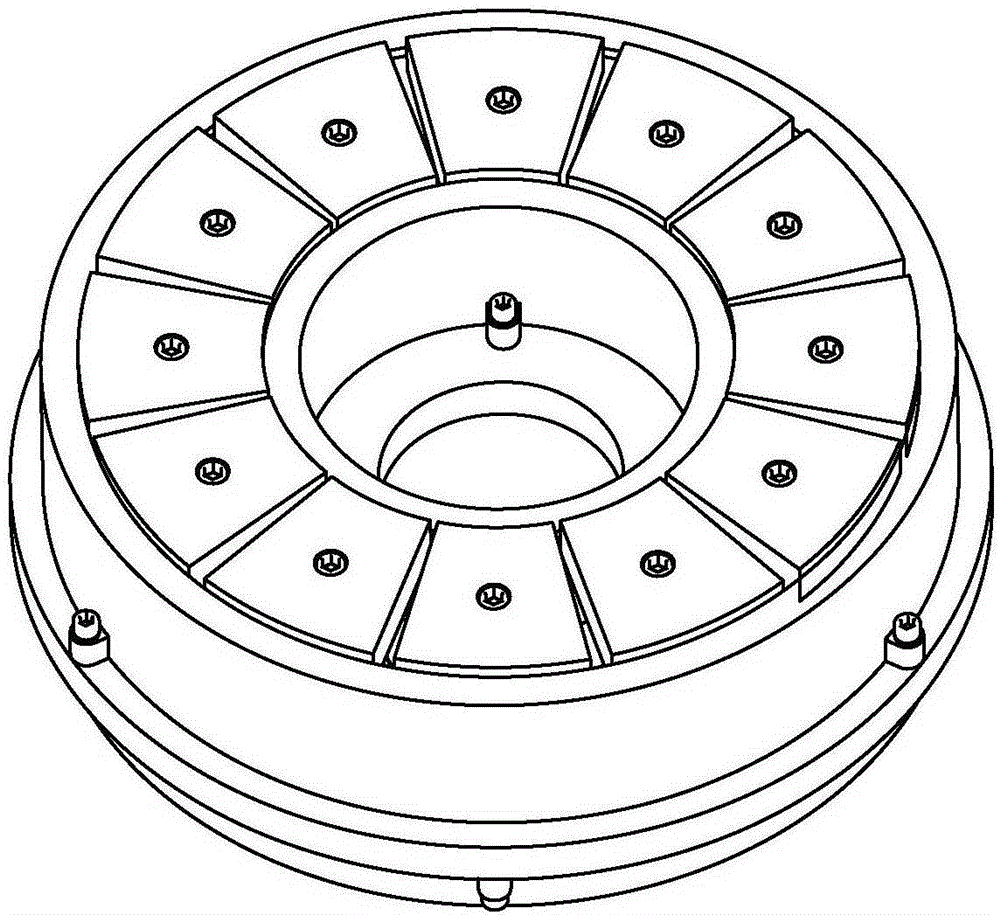

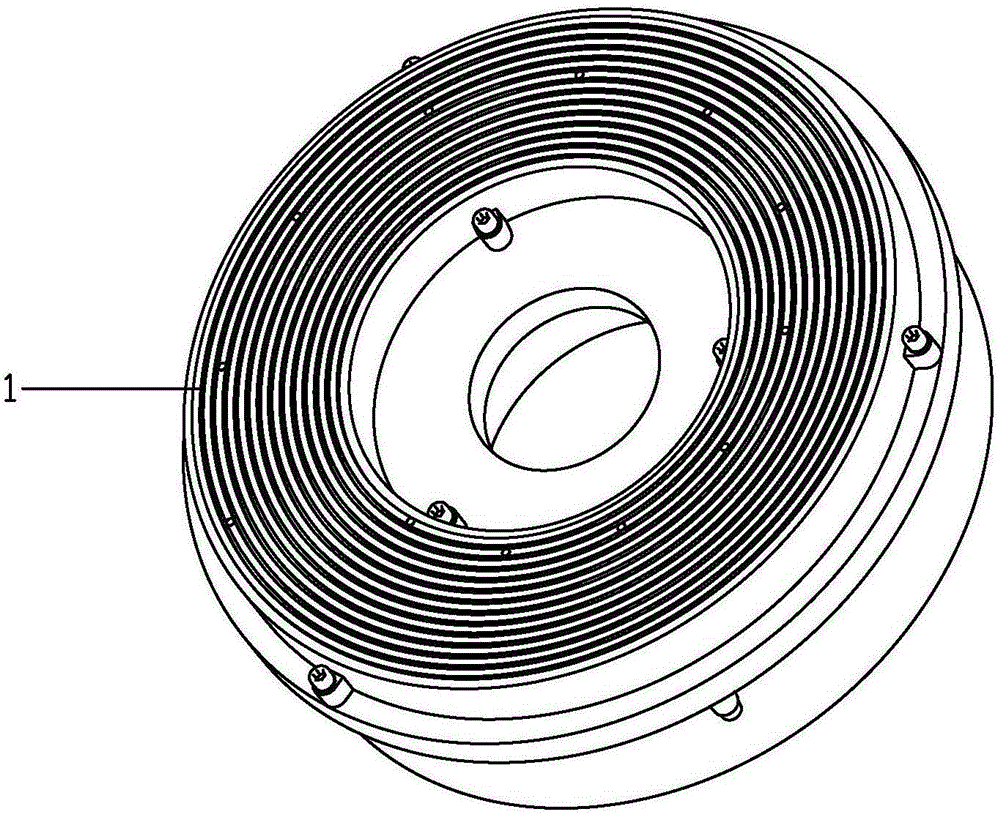

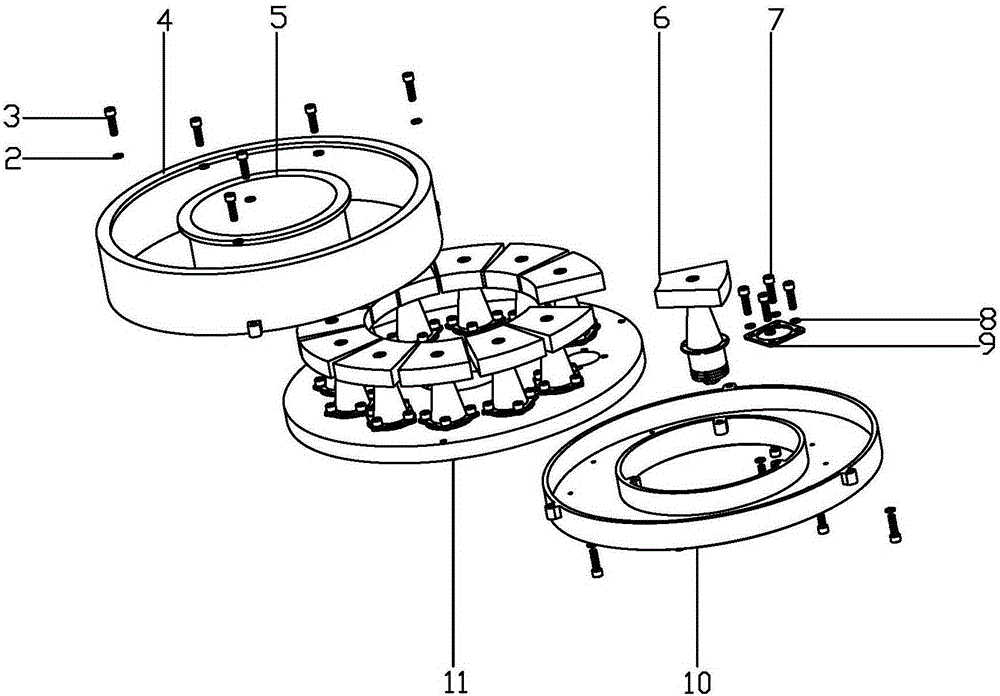

[0032] see figure 1 with figure 2 As shown, a large-size axial ultrasonic-assisted end face grinding grinding disc of the present invention includes: an outer cover 4, an inner cover 5, a coil cover 10, a base plate 11 and several ultrasonic vibrating blocks 6;

[0033] The base plate 11 is concentric, and the lower end of the base plate 11 is provided with a coil 1, and its central hole is used for mounting the motor spindle; the plurality of ultrasonic vibration blocks 6 are evenly distributed along the circumferential direction of the base plate 11; the inner cover 5 is installed on the inner ring of the concentric circle of the base plate 11; the outer cover 4 is installed on the outer ring of the concentric circle of the base plate 11; the coil cover 10 is installed on the lower end of the base plate 11;

[0034] The ultrasonic vibrating block 6 includes an ultrasonic transducer 12, a horn 13 and a grinding block 14; the grinding block 14 is connected to the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com