Automatic packaging machine

An automatic packaging machine and fan technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of different flow rates, reduce the content of sauerkraut oil, inconvenience, etc., to prevent shrinkage, avoid gaps, and prevent seasoning compaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

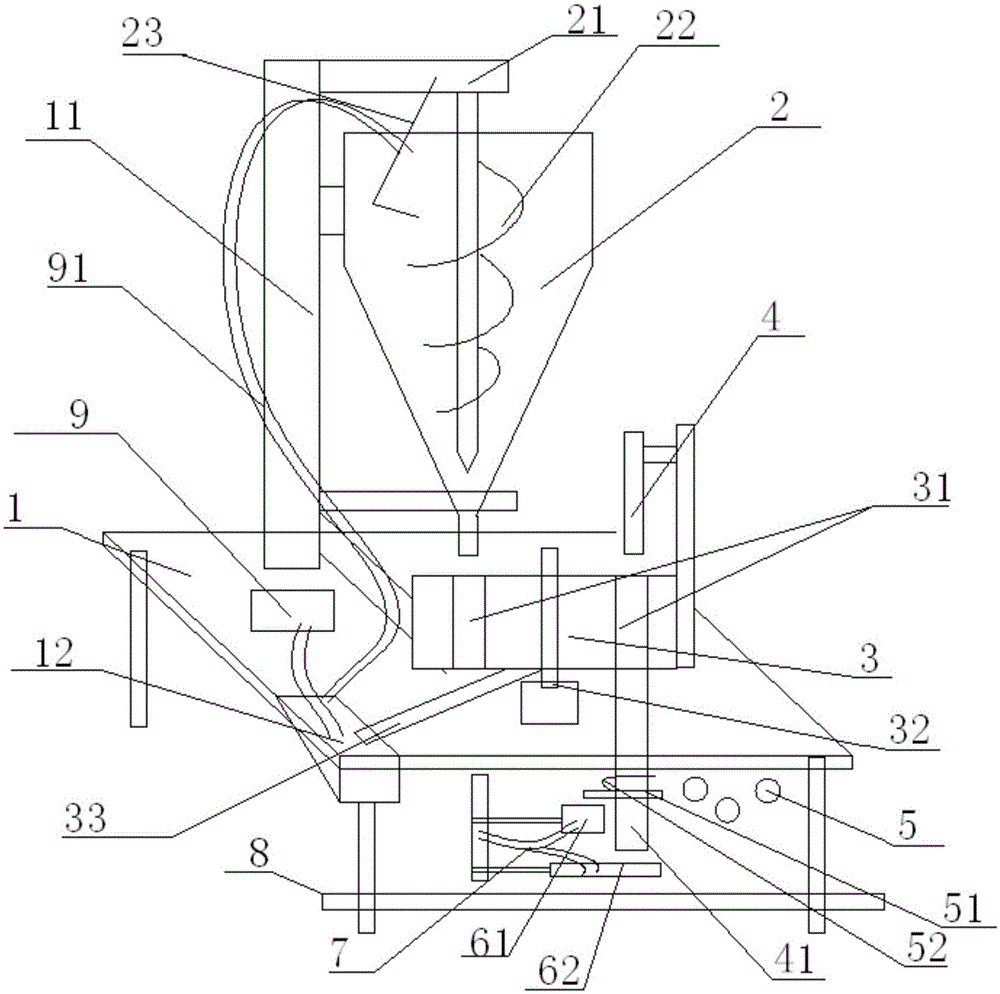

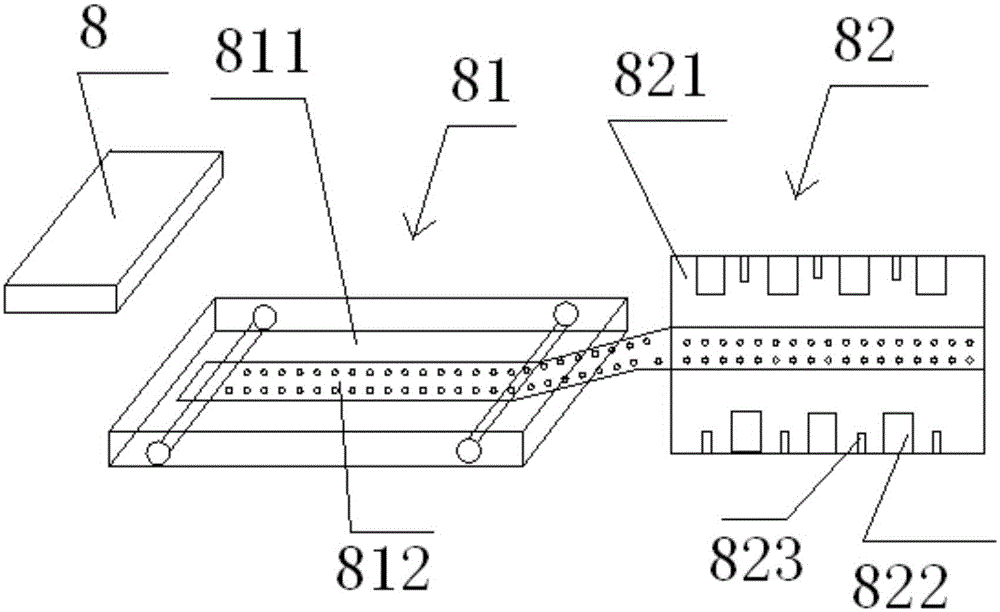

[0021] An automatic packaging machine such as figure 1 , 2 As shown, it includes a workbench 1, a hopper 2, a feeding mechanism, a roll film folding mechanism, a packaging mechanism and a conveyor belt 8; the workbench 1 is provided with a column 11 and an oil collection tank 12, and the hopper 2 is fixedly installed on the column 11 The feeding mechanism includes a material guide plate 3, a material guide plate drive motor 32, an air ejector rod 4, and a material guide tube 41, and the material guide plate 3 is provided with a material guide hole 31, and the material guide hole 31 is arranged along the The material guide plate 3 is evenly distributed in the circumferential direction, and the material guide hole 31 is located below the hopper 2, and the material guide tube 41 is located below the air ejector pin 4, and the material guide hole 31 is located between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com