Inside assembly lifting method of bridge crane in factory building under closed environment

A bridge crane, closed environment technology, applied in the directions of walking bridge cranes, cranes, transportation and packaging, etc., can solve the problems of lack of progress, accuracy, safety and quality, reduce investment costs, improve construction efficiency, Guaranteed quality and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

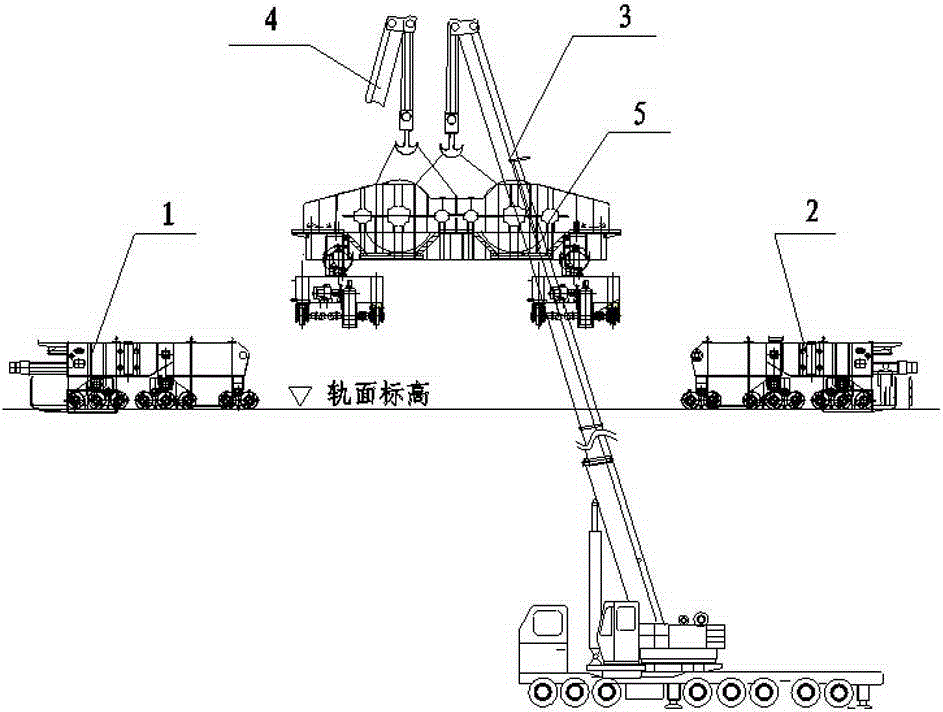

[0017] Now in conjunction with the accompanying drawings and embodiments, the method of assembly and hoisting of the bridge crane in the factory building under the closed environment proposed by the present invention will be further described in detail.

[0018] According to the present invention, a method for assembling and hoisting an bridge crane in a workshop in a closed environment, said assembling and hoisting includes the following steps:

[0019] 1) Preparations before construction: conduct a second retest on the driving beam track of the original factory building, clean up the hoisting ground site at the same time, and inspect the installation tools;

[0020] 2) Assembly of the main beam: adjust the height of both ends of the main beam to make them equal, measure the camber and side camber, and then assemble the accessories on the main beam to the specified position of the main beam;

[0021] 3) Hoisting of the main beam: the main beam includes A main beam 1 and B mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com