Silica brick for hot blast stove

A hot blast stove and silica brick technology, which is applied in the field of refractory materials for hot blast stoves, can solve the problems of cumbersome production process and fluorite content, and achieve the effects of simplifying the production process, reducing cracks in silica bricks, and excellent high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

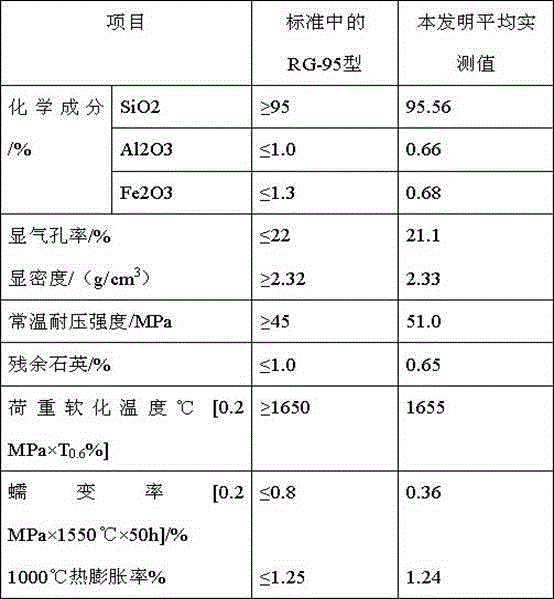

Examples

Embodiment 1

[0045]Silica bricks for hot blast stoves, the weight percentage of the components is: 28% of silica with a particle size of 2.18mm, 41% of silica with a particle size of 1.65mm, 10% of silica with a particle size of 2 Content≥98%, Fe 2 o 3 Content≤0.50%, Al 2 o 3 Content≤0.5%. Waste brick clinker is SiO 2 Waste silica clinker with a content of not less than 94.5%. The addition of composite additives is 6.5%, which is a mixture of lime, iron scale and water. The content of CaO in the composite additives is 25%, and the content of iron scale is 5%; the addition of special additives is 3.7%, and the mass percentage of each component For: bentonite: 25%, calcium hydroxide powder: 30%, clay: 20%, feldspar powder: 10%. The addition of pulp is 0.8%.

[0046] The firing process is:

[0047] (1) Weigh silica, waste brick clinker, and special additives according to the composition ratio of the above claims, and dry mix them uniformly in a wet mill to form a mixture A, and weigh a...

Embodiment 2

[0053] Silica bricks for hot blast stoves, the mass parts of the components are: 30 parts of silica with a particle size of 2.18mm, 28 parts of silica with a particle size of 1.65mm, 18 parts of silica with a particle size of 2 Content≥98%, Fe 2 o 3 Content≤0.50%, Al 2 o 3 Content≤0.5%. Waste brick clinker is SiO 2 Waste silica clinker with a content of not less than 94.5%. The addition of composite additive is 7.0%, which is a mixture of lime, iron scale and water. In the composite additive, CaO: 27%, the content of iron scale is 4%; the special additive is 4.5%, and the mass percentage of each component is: Bentonite: 35%, calcium hydroxide powder 35%, clay: 25%, feldspar powder: 20%. The amount of pulp added was 1.2%. Using calcium hydroxide powder instead of fluorite has low cost, no toxic and side effects, simple preparation process, excellent product performance, and is suitable for mass production.

[0054] The firing process is:

[0055] (1) Weigh silica, waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com