Preparation method of water-based silver nanowire ink

A preparation method and technology of silver nanowires, applied in inks, household appliances, applications, etc., can solve problems such as poor water-based ink additives, and achieve convenient mass production and use, high conductivity and light transmittance, transparent The effect of high light rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

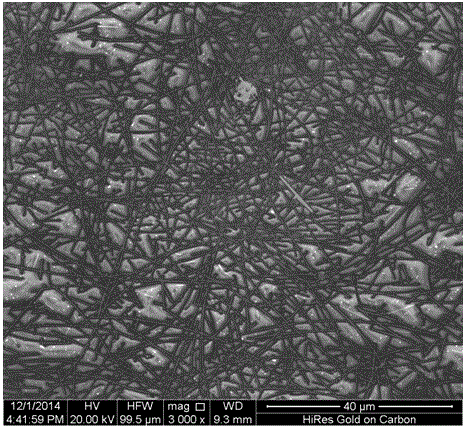

Image

Examples

Embodiment

[0023] Silver nanowires with a diameter of 30-50 nm and a length of 10-20 μm are used as conductive substances. Sodium carboxymethyl cellulose is used as binder, ZonylFSO-100 is used as surfactant, SpredoxD-260 is used as dispersing anti-settling agent, propylene glycol methyl ether is used as leveling agent, 2-hexyl alcohol is used as defoaming agent, and water is used as solvent. Prepare slurry;

[0024] Sodium carboxymethyl cellulose was formulated as a 1.5% aqueous solution (note: greater concentration would result in too high a viscosity to be taken out). Then determine the content of these components and calculate the mass required for each additive. Add the rest of the material except the sodium carboxymethylcellulose solution into the flask and stir to mix for 20 minutes. Then the sodium carboxymethylcellulose solution was slowly dripped into the slurry, and the stirring was continued for 30 minutes. Finally, the slurry was filtered through a filter membrane with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com