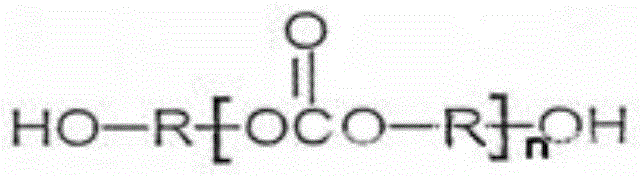

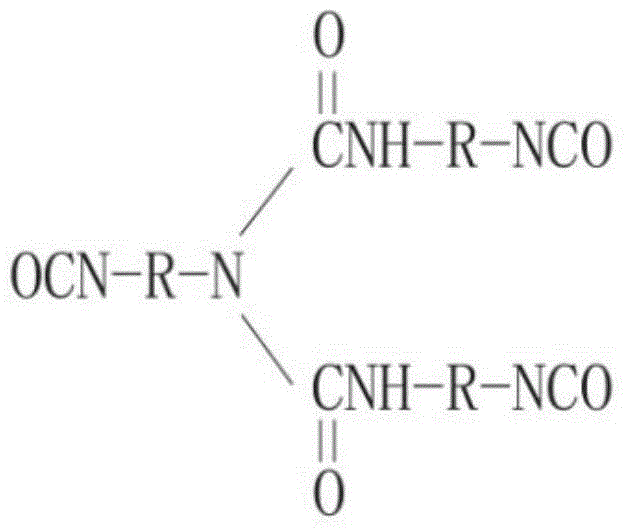

Aliphatic polyurethane curing agent and preparation method thereof

An aliphatic polyurethane and curing agent technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to use concrete structure protective topcoat, low elasticity or elongation at break, poor weather resistance, etc., and achieve excellent physical properties Mechanical properties, satisfying durability, and the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The preparation of aliphatic polyurethane curing agent of the present invention:

[0071] The proportioning ratio of each component of the aliphatic polyurethane curing agent of the present invention is as follows: 28g HDI biuret, 25g liquid polycarbonate diol, 35g butyl acetate and 3g HDI trimer;

[0072] Add the liquid polycarbonate diol into the reactor, raise the temperature to 110°C, dehydrate under vacuum (-0.05~0.09MPa) for 30min, then cool down to 75°C; then add butyl acetate and HDI biuret, 75 Stir at constant temperature for 2 hours at ℃; then cool down to 40℃, add HDI trimer, stir for 30 minutes, and filter to obtain the aliphatic polyurethane curing agent of the present invention.

Embodiment 2

[0074] The preparation of aliphatic polyurethane curing agent of the present invention:

[0075] The proportioning ratio of each component of the aliphatic polyurethane curing agent of the present invention is as follows: 30g HDI biuret, 30g liquid polycarbonate diol, 40g butyl acetate and 5g HDI trimer;

[0076] Add the liquid polycarbonate diol into the reactor, raise the temperature to 120°C, dehydrate under vacuum (-0.05~0.09MPa) for 30min, then cool down to 85°C; then add butyl acetate and HDI biuret, 85 Stir at constant temperature for 2 hours at ℃; then cool down to 45℃, add HDI trimer, stir for 30 minutes, and filter to obtain the aliphatic polyurethane curing agent of the present invention.

Embodiment 3

[0078] The technical parameters of the aliphatic polyurethane elastic curing agent prepared in Examples 1 and 2 and the aliphatic polyurethane elastic curing agent in the prior art are shown in Table 1 and Table 2, respectively.

[0079] Table 1: Technical parameters of the aliphatic polyurethane elastic curing agent prepared in Examples 1 and 2

[0080]

[0081] Table 2: Technical parameters of aliphatic polyurethane elastic curing agent in the prior art

[0082]

[0083] Conclusion: aliphatic polyurethane elastic curing agent of the present invention compares with prior art curing agent, and the former isocyanate (NCO) content is lower, and non-volatile matter content is also lower simultaneously, and it is mainly because aliphatic polyurethane of the present invention A flexible polycarbonate structure is introduced into the molecular structure of the elastic curing agent, thereby reducing the NCO content and non-volatile matter, and improving the elasticity of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com