Production technology of fermented glutinous rice yogurt

A production process and a technology for sour yogurt are applied in the field of production technology of rice-stuffed sour yogurt to achieve the effect of improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

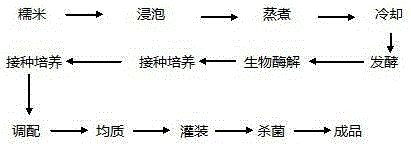

Image

Examples

Embodiment 1

[0029] A production process of rice-brewed yogurt, comprising the following steps:

[0030] (1) Soaking: Soak glutinous rice in running water for 24-48 hours;

[0031] (2) Cooking: Rinse the glutinous rice with water after soaking, drain and steam for 8-10 minutes;

[0032] (3) Cooling: cool down the steamed glutinous rice with water to 25-30°C;

[0033] (4) Fermentation: add rice wine koji, the weight of the added rice wine koji is 0.1-0.5% of the weight of glutinous rice, mix the koji evenly; put the glutinous rice mixed with koji into a box and enter the fermentation room for fermentation, the fermentation temperature is 25-30 °C, ferment for 2-3 days to obtain raw juice rice wine; the obtained raw juice rice wine has a soluble solid content of more than 35%, an acidity of 0.4-0.6g / 100g in terms of lactic acid, and an alcohol content of 1.5-3.5%vol;

[0034] (5) Biological enzymatic hydrolysis: Grind the original juice rice wine with a colloid mill, the particle size afte...

Embodiment 2

[0039] A production process of rice-brewed yogurt, comprising the following steps:

[0040] (1) Soaking: Soak glutinous rice in running water for 24-48 hours; the quality of glutinous rice meets the control requirements of the national standard GB1354-2009;

[0041] (2) Cooking: Rinse the glutinous rice with water after soaking, drain and steam for 8-10 minutes; soak in running water to prevent the glutinous rice from becoming sour. Heart and glutinous rice are easy to disperse and not sticky;

[0042] (3) Cooling: Cool down the steamed glutinous rice with water, and disperse after cooling down to 25-30°C, so that there is no agglomeration;

[0043] (4) Fermentation: Add rice wine koji, the weight of the added rice wine koji is 0.1-0.5% of the weight of glutinous rice, mix the koji evenly; put the glutinous rice mixed with koji into a box and enter the fermentation room for fermentation, the glutinous rice mixed with koji should be It is advisable not to see the koji; the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com