Dark-fermentation photosynthetic united hydrogen production device and method

A technology of photosynthesis and dark fermentation, which is applied in the direction of bioreactor/fermenter combination, fermentation, biochemical cleaning equipment, etc., to achieve good application prospects, reduce energy consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

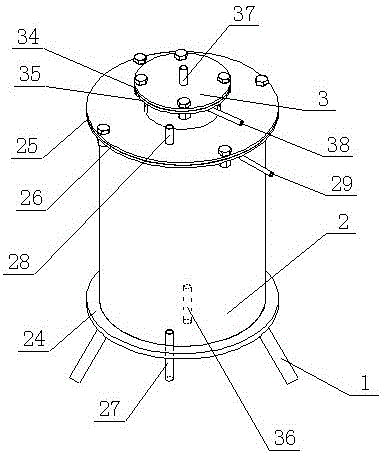

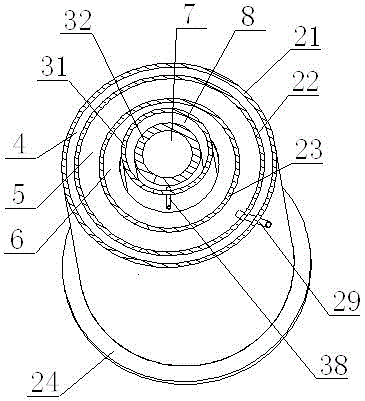

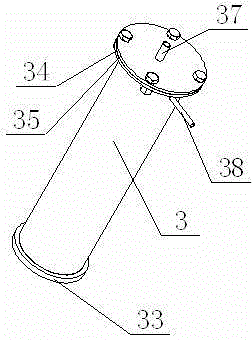

[0038] Embodiment one: if figure 1 , figure 2 As shown, a dark fermentation photosynthesis combined hydrogen production device according to the present invention includes a support 1, a photosynthetic biological hydrogen production reactor 2 is placed on the support 1, and a dark Fermentative biological hydrogen production reactor 3, and the top of dark fermentation biological hydrogen production reactor 3 is higher than the top of photosynthetic biological hydrogen production reactor 2, so as to facilitate the discharge of dark fermentation hydrogen production reaction liquid, said photosynthetic biological hydrogen production reactor 2 and the dark fermentation biological hydrogen production reactor 3 are provided with a light insulation layer 6, the light insulation insulation layer 6 is provided with a light source, and the light source is directed towards the photosynthetic biological hydrogen production reactor 2, effectively ensuring the dark fermentation process The ...

Embodiment 1

[0051] The method for producing hydrogen by the dark fermentation photosynthesis combined hydrogen production device described in Embodiment 1 comprises the following steps:

[0052] A: First, connect one end of the constant flow pump with the reaction liquid storage container with a rubber tube, and connect the other end of the constant flow pump with the dark reaction liquid inlet pipe 36 with a rubber pipe, and then connect the dark reaction liquid outlet pipe 38 with the light reaction The liquid inlet pipe 27 is connected with a rubber tube, the photoreaction liquid outlet pipe 29 is connected with the waste liquid collection container with a rubber tube, and finally the photoreaction hydrogen gas outlet pipe 28 and the dark reaction hydrogen gas outlet pipe 37 are connected with the rubber tube for hydrogen collection and storage tank. The pipes are connected.

[0053] B: After the device is connected, check the air tightness of the device. If an air leak is found, effec...

Embodiment 2

[0060] Embodiment two: if Figure 4 , Figure 5 , Figure 6As shown, there is no overall change in the dark fermentation photosynthesis combined hydrogen production device in this embodiment, and the difference is mainly that eight vertical light baffles 9 are used to divide the photoreaction chamber 5 into eight mutually independent photosynthetic chambers along the circumferential direction. Action reaction chamber, that is, the first photosynthesis reaction chamber, the second photosynthesis reaction chamber, the third photosynthesis reaction chamber, the fourth photosynthesis reaction chamber, the fifth photosynthesis reaction chamber, the sixth photosynthesis reaction chamber Action reaction chamber, the seventh photosynthesis reaction chamber, and the eighth photosynthesis reaction chamber, these eight mutually independent photosynthesis reaction chambers are all equipped with photoreaction liquid inlet pipe 27 and photoreaction liquid outlet pipe 29, eight Two vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com