Extraction method of tuna polypeptide

An extraction method and technology of tuna, which is applied in the field of extraction of tuna peptides, can solve the problems of high peptide yield and fishy smell of tuna peptides, and achieve the effects of high peptide yield, easy absorption by human body, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

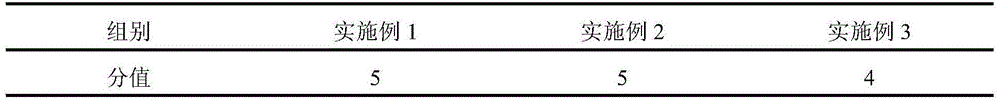

Embodiment 1

[0028] A method for extracting tuna polypeptides, comprising the following steps:

[0029] (1) Wash the fresh tuna leftovers and twist them into minced tuna;

[0030] (2) Mix the minced tuna meat with the NaCl solution with a concentration of 0.4mol / L at a mass ratio of 1:8, and use a magnetic constant temperature stirrer to extract the mixed solution at 10°C and a stirring speed of 500r / min for 1 hour;

[0031] (3) After the leaching is completed, filter the leaching solution to obtain the feed liquid, use 0.01mol / L hydrochloric acid solution to adjust the pH of the feed liquid to 5.0, and then add modified bentonite with a mass ratio of 1:10 to the feed liquid , react for 45min;

[0032] (4) After the reaction is completed, use 0.01mol / L NaOH solution to adjust the pH of the feed solution to 7.0, centrifuge the feed solution at 8000r / min for 20min, and take the supernatant;

[0033] (5) Add neutral protease and compound protease accounting for 4% of the mass of the superna...

Embodiment 2

[0040] A preparation method of tuna freeze-dried powder, comprising the following steps:

[0041] (1) Clean the fresh tuna after removing the viscera, and twist it into minced tuna;

[0042] (2) Mix the minced tuna meat and the NaCl solution with a concentration of 0.45mol / L at a mass ratio of 1:9, and use a magnetic stirrer to extract the mixed solution at 12°C and a stirring speed of 600r / min for 1.5h;

[0043] (3) After the leaching is completed, filter the leaching solution to obtain the feed liquid, use 0.01mol / L hydrochloric acid solution to adjust the pH of the feed liquid to 5.2, and then add modified bentonite with a mass ratio of 1:11 to the feed liquid , react for 50min;

[0044] (4) After the reaction is completed, use 0.01mol / L NaOH solution to adjust the pH of the feed solution to neutrality, then centrifuge the feed solution at 9000r / min for 25min, and take the supernatant;

[0045] (5) Add neutral protease and compound protease accounting for 5% of the mass o...

Embodiment 3

[0052] A preparation method of tuna freeze-dried powder, is characterized in that, comprises the following steps:

[0053] (1) Clean the fresh tuna after removing the viscera, and twist it into minced tuna;

[0054] (2) Mix the minced tuna meat and the NaCl solution with a concentration of 0.5mol / L at a mass ratio of 1:10, and use a magnetic stirrer to extract the mixed solution at 15°C and a stirring speed of 700r / min for 2 hours;

[0055] (3) After the leaching is completed, filter the leaching solution to obtain the feed liquid, use 0.01mol / L hydrochloric acid solution to adjust the pH of the feed liquid to 5.5, and then add modified bentonite with a mass ratio of 1:12 to the feed liquid , react for 60min;

[0056] (4) After the reaction is completed, use 0.01mol / L NaOH solution to adjust the pH of the feed solution to neutrality, then centrifuge the feed solution at 10000r / min for 30min, and take the supernatant;

[0057] (5) Add neutral protease and compound protease ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com