Manufacturing technology of chip-free RFID label

A technology of RFID tags and manufacturing process, which is applied in the field of radio frequency identification, can solve the problems of high prices of RFID tags and reading equipment, and achieve the effects of low manufacturing cost, simple and easy operation process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

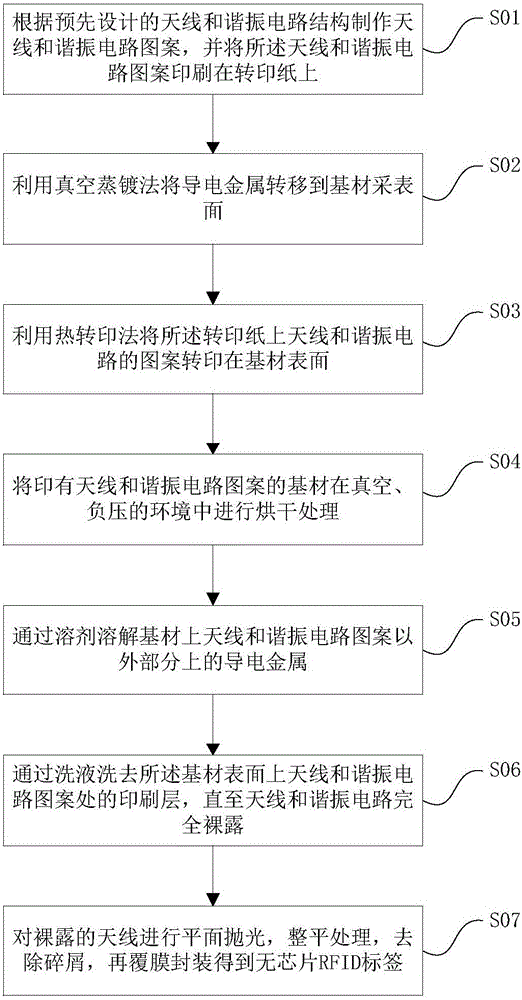

[0028] Such as figure 1 As shown, a flow chart of the manufacturing process of a chipless RFID tag, including:

[0029] Step S01: making an antenna pattern according to the pre-designed antenna and resonant circuit structure, and printing the antenna and resonant circuit pattern on transfer paper;

[0030] Step S02: transfer the conductive metal to the surface of the substrate by vacuum evaporation;

[0031] Step S03: transfer the patterns of the antenna and the resonant circuit on the transfer paper to the surface of the substrate by thermal transfer method;

[0032] Step S04: drying the base material printed with antenna and resonant circuit patterns in a vacuum and negative pressure environment;

[0033] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com