A method of manufacturing a semiconductor device with cross-line field plates

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as complex field plate manufacturing methods, and achieve the effects of simple manufacturing methods, balanced electric field distribution, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For simplicity, some technical features known to those skilled in the art are omitted from the following description.

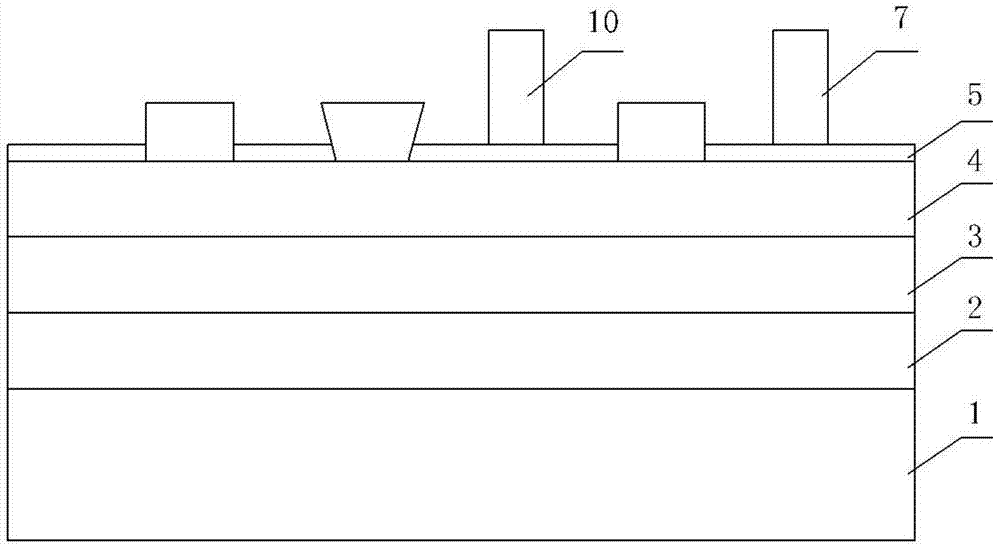

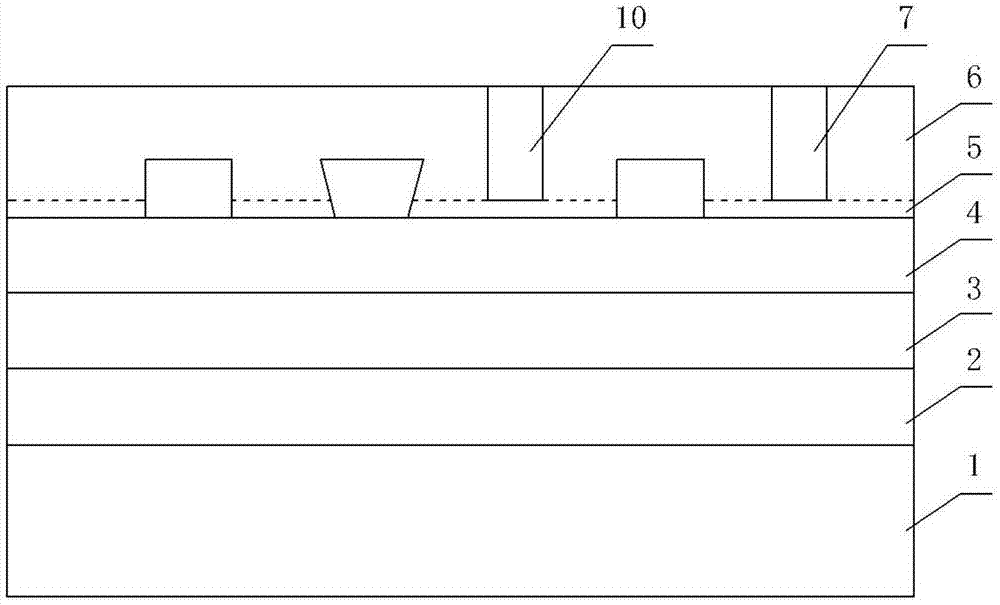

[0025] According to one embodiment of the present invention, a method for manufacturing a semiconductor device with cross-line field plates is provided, a substrate 1 is provided, and a nucleation layer 2, a buffer layer 3, and a barrier layer 4 are sequentially formed on the substrate 1, and the Forming the gate 11, the source 12 and the drain 8 on the barrier layer 4 also includes the following steps:

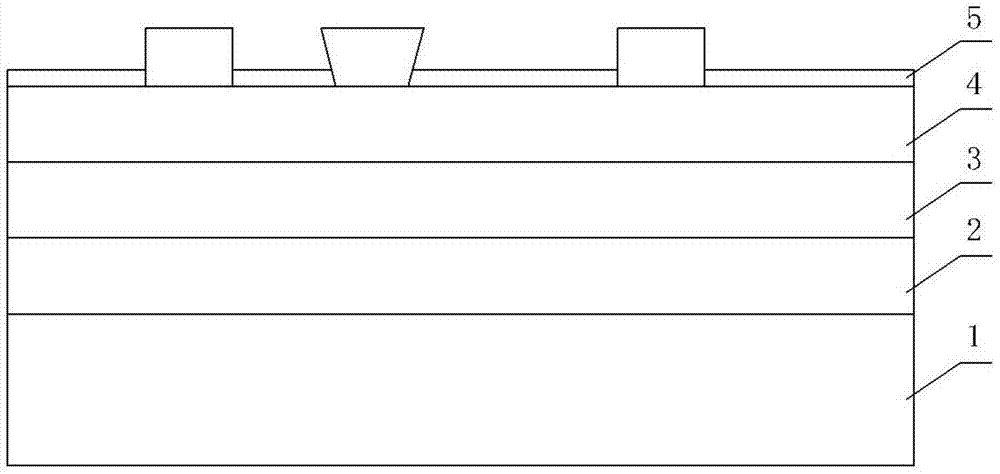

[0026] S1, such as figure 1 As shown, the first layer of dielectric layer 5 is deposited on the barrier layer 4, and the dielectric layer can be made of SiO2 or SiNX material to allow the subsequent processing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com