Air cathode and microbial fuel cell

An air cathode and fuel cell technology, applied in the fields of materials, energy, and environment, can solve problems to be improved, and achieve the effect of improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

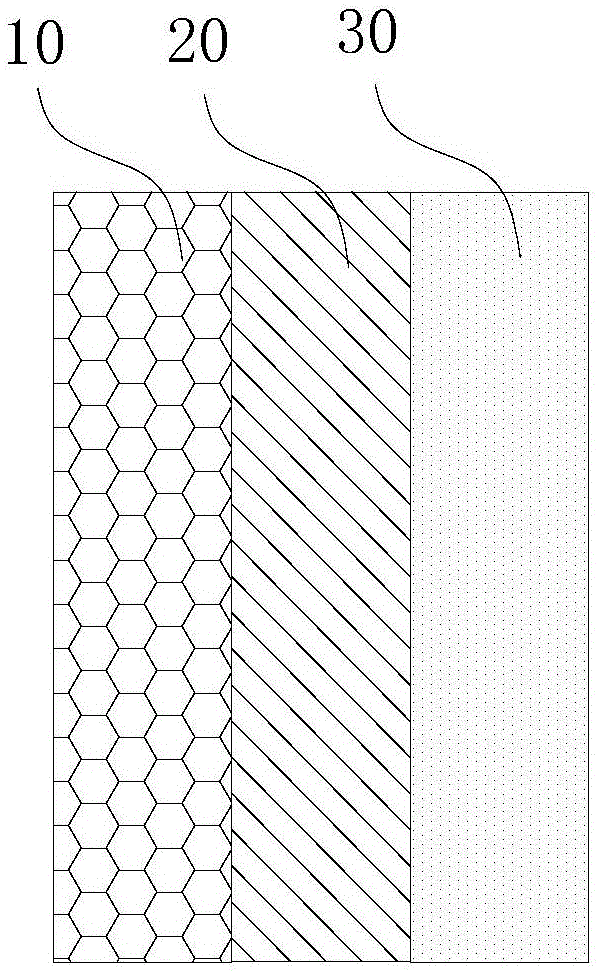

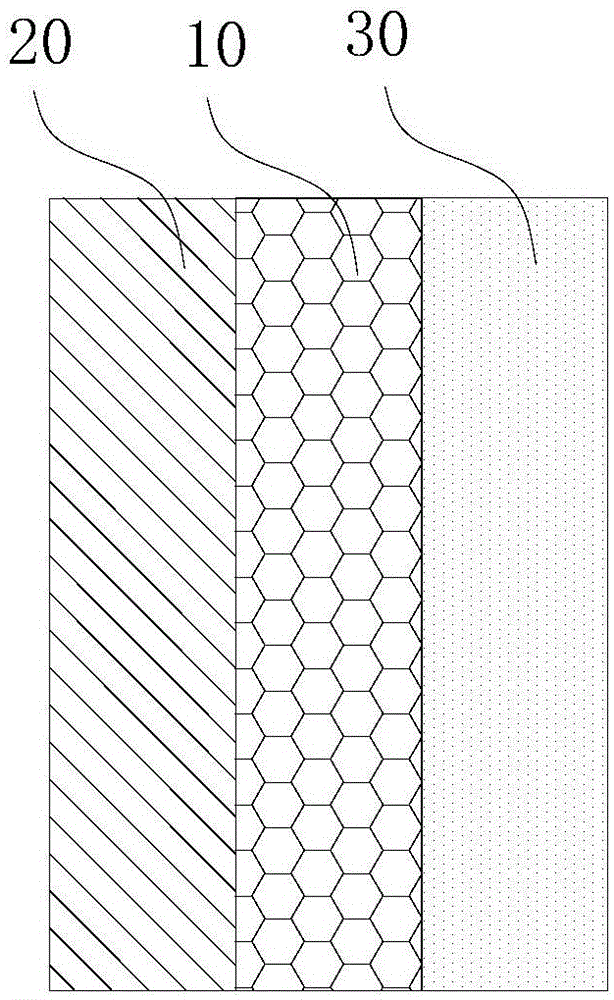

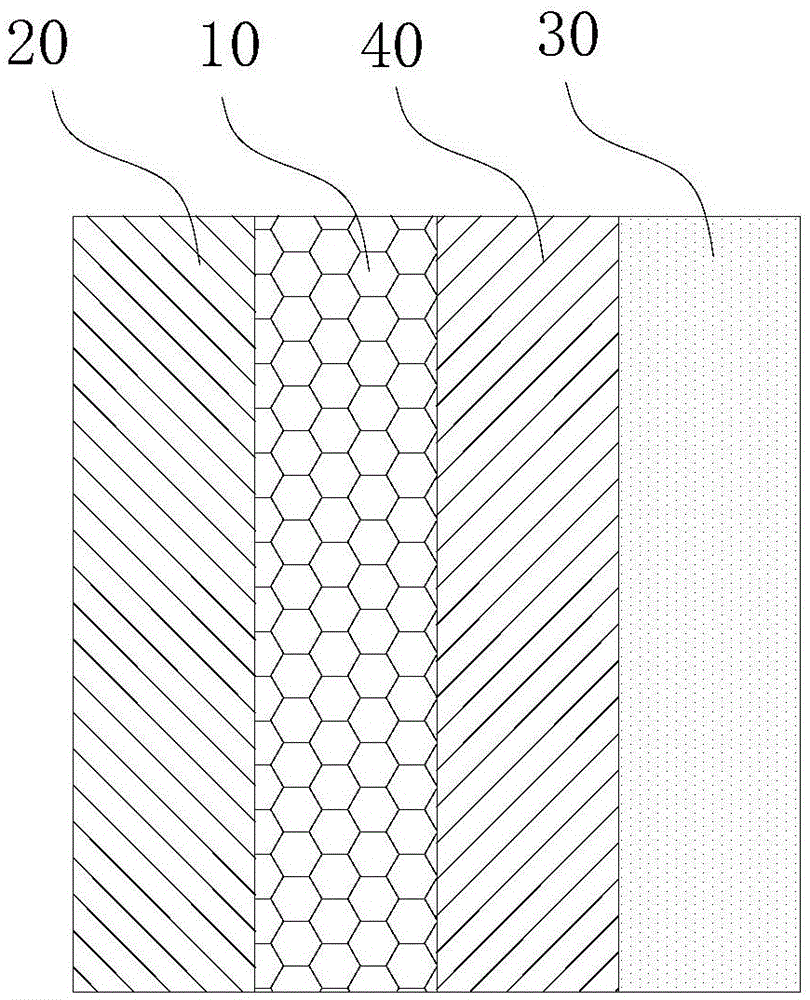

Method used

Image

Examples

Embodiment 1

[0076] Preparation of cathode catalyst: mixing and grinding sodium chloride and zinc chloride evenly, wherein the molar ratio of zinc chloride is 40-45%. Add 1 g of 1-ethyl-3-methylimidazolium dicyanamide per 13 g of sodium chloride and zinc chloride mixture. The mixture was heated in a muffle furnace to 1000°C at a ramp rate of 2.5°C / min, kept at this temperature for 60-70 minutes, and then cooled to room temperature. The whole process was carried out under the protection of nitrogen. To remove residual metal salts and thus obtain a porous structure, the heat-treated samples were washed in water for several hours, filtered and dried in vacuum. The as-prepared nitrogen-doped carbon was detected by X-ray photoelectron spectroscopy (XPS). specifically, Figure 8 (c) is the nitrogen-doped carbon photoelectron spectrum, Figure 8 (d) is the fine energy spectrum of N1s. According to an embodiment of the present invention, refer to Figure 8 (c), the nitrogen content of the pr...

Embodiment 2

[0081] Referring to Embodiment 1, the difference is that in the process of preparing the catalytic layer, the mass of the catalyst NDC is weighed to be 35 mg, and the catalyst loading corresponding to the air cathode is 3 mg / cm 2 , add 16 μL of 60 mass% PTFE and 270 μL of deionized water to obtain air cathode NDC3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com