Filter material for air filter, method for manufacturing same, and air filter provided with same

A technology for air filters and filter materials, which is applied in the field of filter materials for air filters, and can solve the problems of increased capture efficiency of filter materials, increased pressure loss of filter materials, and increased power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

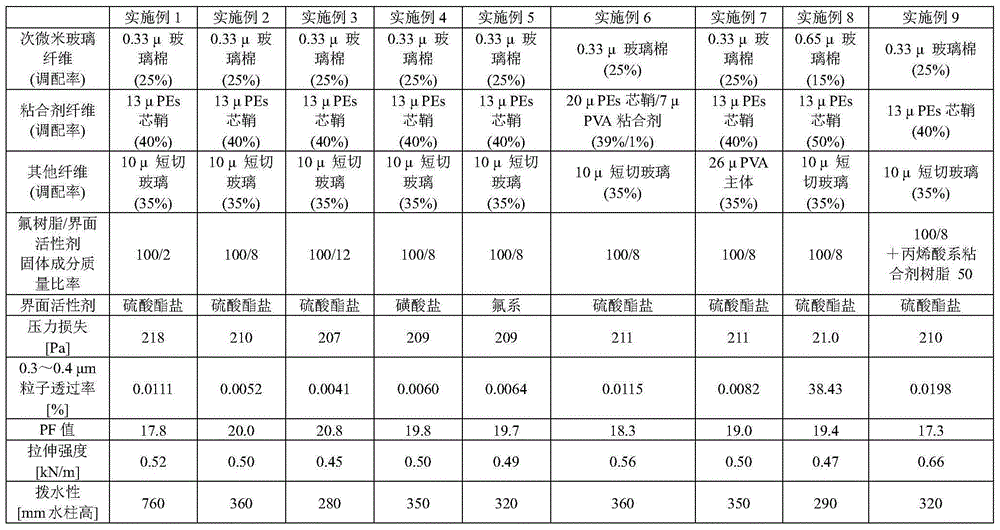

Embodiment 1

[0048] Submicron glass wool fiber (B-00-F, average fiber diameter 0.33 μm, manufactured by Lauscha Fiber International Co.) 25 parts by mass, polyester core sheath binder fiber (Ester4080, fineness 1.7dtx (fiber diameter 13 μm), fiber length 5mm , manufactured by Unitika Co., Ltd.) 40 parts by mass, 35 parts by mass of chopped glass fiber (CS06JAGP024, fiber diameter 10 μm, fiber length 6 mm, manufactured by Owens Corning (Japan) Co., Ltd.) In water having a value of 3.0, it was pulverized using a beater to obtain a fiber slurry having a solid content concentration of 0.5%. Next, the obtained slurry was made into paper using a papermaking cylinder to obtain wet paper. Next, 100 parts of fluororesin (NKGUARDS-09, manufactured by Nikka Chemical Co., Ltd.) and 2 parts of alkyl sulfate sodium salt surfactant (Emal10G, manufactured by Kao Corporation) were added to water and the solid content concentration was adjusted to 0.204% by mass to obtain an impregnating liquid, apply this...

Embodiment 2

[0050] Use 100 parts of fluororesin (NKGUARDS-09, manufactured by Nichika Chemical Co., Ltd.)) and 8 parts of alkylsulfate sodium salt surfactant (Emal10G, manufactured by Kao Co., Ltd.) were added to water and the solid content concentration was adjusted to 0.216% by mass of the impregnation solution, except that, in the same manner as in Example 1 to obtain a basis weight of 80g / m 2 filter media for air filters. In addition, the impregnation adhesion amount of the impregnating liquid is converted to a solid content of 0.8g / m 2 .

Embodiment 3

[0052] Add 100 parts of fluororesin (NKGUARDS-09, manufactured by Nichika Chemical Co., Ltd.) and 12 parts of alkyl sulfate sodium salt surfactant (Emal10G, manufactured by Kao Corporation) to water and adjust the solid content concentration to 0.224 The impregnating liquid of mass %, except that, obtain basis weight 80g / m in the same manner as Example 1 2 filter media for air filters. In addition, the impregnation adhesion amount of the impregnating liquid is converted to a solid content of 0.8g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com