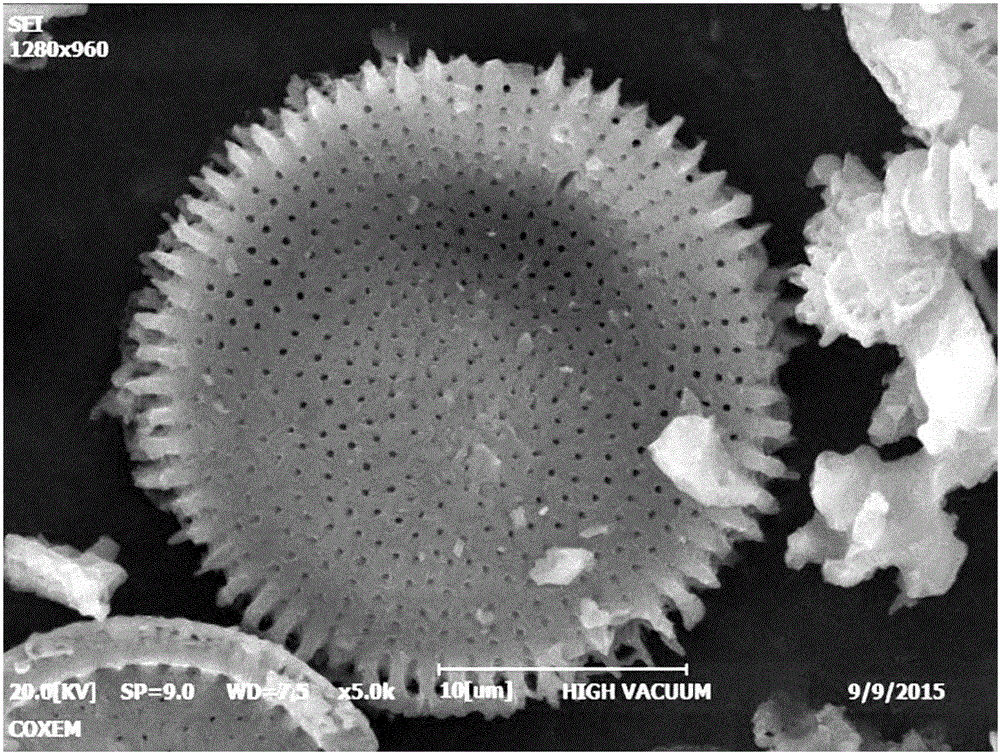

Kieselguhr insecticide, and preparation method and application thereof

An insecticide and diatomite technology, which is applied in the field of pesticides, can solve the problems of complex composition, unsatisfactory insecticidal effect, environmental pollution and the like, and achieves the effects of simple preparation method, suitability for industrial production and high insecticidal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] 1. Formula

[0062] A diatomaceous earth insecticide, comprising: 320-360 mesh amorphous SiO 2 The mass percentage content of 92% diatomite powder is 82%; the mass percentage content of 320-360 mesh pyrethrin is 1.8% of 25% pyrethrin powder and 16.2% of first-grade sepiolite powder.

[0063] 2. Preparation method

[0064] 1) material preparation: prepare the diatomite powder, pyrethrum powder and sepiolite powder of above-mentioned formula quantity;

[0065] 2) Mixing: After mixing the diatomaceous earth powder, pyrethrum powder and sepiolite powder in the prescribed amount, use a high-efficiency mixing unit to fully stir for 4 hours to obtain a mixed powder;

[0066] 3) Drying: Dry the mixed powder prepared in step 2) through an airflow flash dryer at a drying temperature of 140° C. and a drying time of 3 hours to obtain a dried powder;

[0067] 4) Classification: the dry powder obtained in step 3) is classified by air selection in a cyclone separator to obtain a pr...

Embodiment 3

[0069] 1. Formula

[0070] A diatomaceous earth insecticide, comprising: 320-360 mesh amorphous SiO 2 The mass percentage content is 95% of diatomite powder 91%; the mass percentage content of 320-360 mesh pyrethrin is 25% pyrethrin powder 1.5% and first-grade sepiolite powder 7.5%.

[0071] 2. Preparation method

[0072] 1) material preparation: prepare the diatomite powder, pyrethrum powder and sepiolite powder of above-mentioned formula quantity;

[0073] 2) Mixing: After mixing the diatomite powder, pyrethrum powder and sepiolite powder in the prescribed amount, use a high-efficiency mixing unit to fully stir for 3 hours to obtain a mixed powder;

[0074] 3) Drying: Dry the mixed powder prepared in step 2) through an airflow flash dryer at a drying temperature of 160° C. and a drying time of 4 hours to obtain a dried powder;

[0075] 4) Classification: the dry powder obtained in step 3) is classified by air selection in a cyclone separator to obtain a product.

Embodiment 4

[0077] 1. Formula

[0078] A diatomaceous earth insecticide, comprising: 320-360 mesh amorphous SiO 2 The mass percentage content is 98% of diatomite powder 85%; the mass percentage content of 320-360 mesh pyrethrin is 25% pyrethrin powder 2.5% and first-grade sepiolite powder 12.5%.

[0079] 2. Preparation method

[0080] 1) material preparation: prepare the diatomite powder, pyrethrum powder and sepiolite powder of above-mentioned formula quantity;

[0081] 2) Mixing: After mixing the diatomaceous earth powder, pyrethrum powder and sepiolite powder in the prescribed amount, use a high-efficiency mixing unit to fully stir for 2.5 hours to obtain a mixed powder;

[0082] 3) Drying: Dry the mixed powder obtained in step 2) through an airflow flash dryer at a drying temperature of 80°C and a drying time of 6 hours to obtain a dried powder;

[0083] 4) Classification: the dry powder obtained in step 3) is classified by air selection in a cyclone separator to obtain a product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com