Tooth crown blade locked through double screws in V-shaped positioning groove

A crown blade and positioning groove technology, which is applied in drilling/drilling equipment, drilling tool accessories, transportation and packaging, etc., can solve the problems of high production cost and complex structure, and achieve improved bearing capacity, large contact area, Good clamping reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

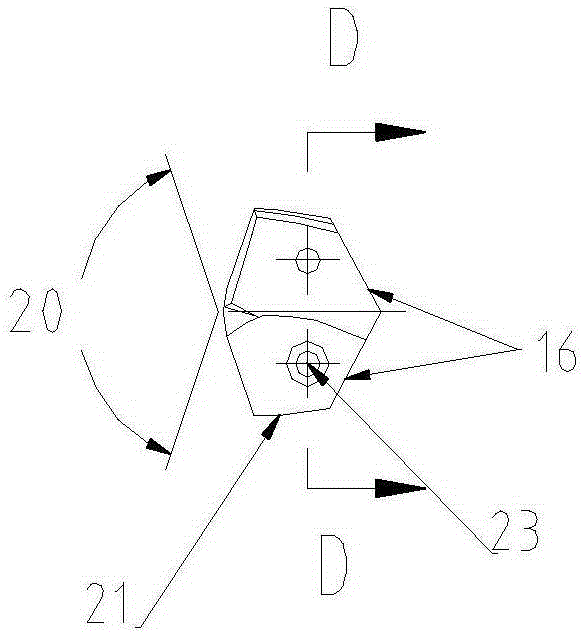

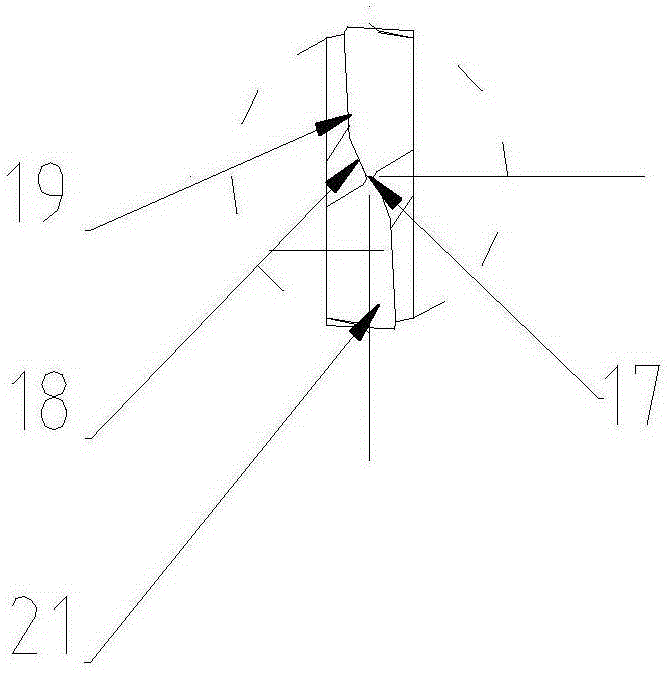

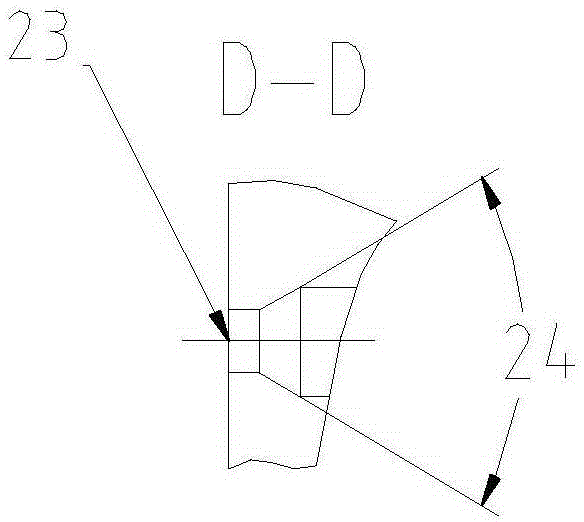

[0022] Such as Figure 1~4 As shown, the crown blade is locked by double screws in the V-shaped positioning groove, and the right end of the crown blade is provided with a V-shaped positioning surface 16 for matching with the positioning surface of the working part of the drill pipe. The included angle of the V-shaped positioning surface 16 is 90° ~140°, the left end of the crown insert is provided with a cutting edge consisting of a chisel edge 17, a transition edge 18 and a main cutting edge 19, the intersection line of the chip flute and the flank forms the main cutting edge 19, and the main cutting edge The formed included angle is apex angle 20°, the angle is 120-140°, the intersection line of the two flanks forms a chisel edge 17, and a transition edge 18 is ground between the main cutting edge and the chisel edge; The tooth crown edge 21, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com