Lapping full-penetration laser welding method for stainless steel heat exchange plates

A heat exchange plate and laser welding technology, which is applied in laser welding equipment, welding equipment, heat exchange equipment, etc., can solve the problems that small plate heat exchange cannot meet production needs, plates are prone to deformation, and corrugation forms are changeable, etc. , to achieve the effect of easy automatic welding, flexible welding path and small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

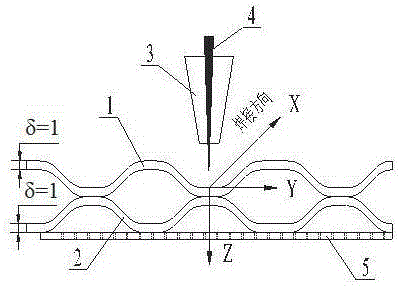

[0019] The present invention and its effects will be further described below in conjunction with the accompanying drawings.

[0020] A full penetration laser welding method for lap joints of stainless steel heat exchange plates, comprising the following steps:

[0021] a) Preparation before welding: first place the copper backing plate with holes on the laser welding machine, then place the heat exchange plate on the copper plate, and then press it with a pressure beam on the front;

[0022] b) Connection method: The lap joints of the heat exchange plates adopt the continuous laser full penetration welding process, which meets the requirements for the strength of the weld seam and the surface quality of the upper and lower heat exchange plates;

[0023] c) Welding parameters: optimized welding parameters are adopted for full penetration lap laser welding: laser power 2150KW, defocus + 6mm, welding speed 3m / min;

[0024] d) Protective gas: During the welding process, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com