Slider Superfinishing Machine

A technology of ultra-finishing machines and sliders, which is applied in the direction of grinding racks, grinding slides, grinding machines, etc. It can solve the problem that the arc profile and surface roughness of the raceway are not easy to be guaranteed, and the profile of the grinding wheel is easy to deform, etc. problem, achieve better anti-seismic effect, lower manufacturing difficulty, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

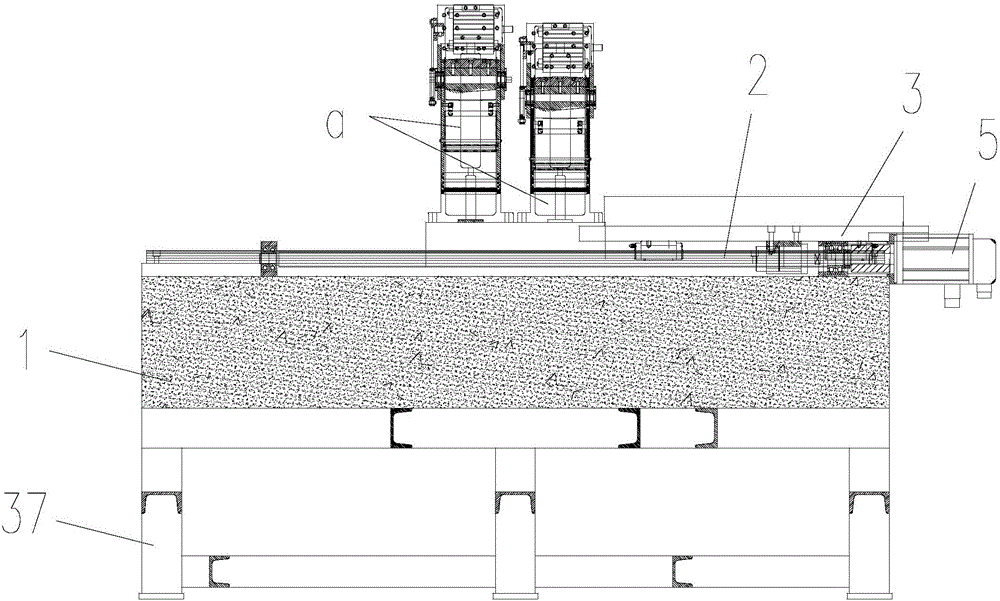

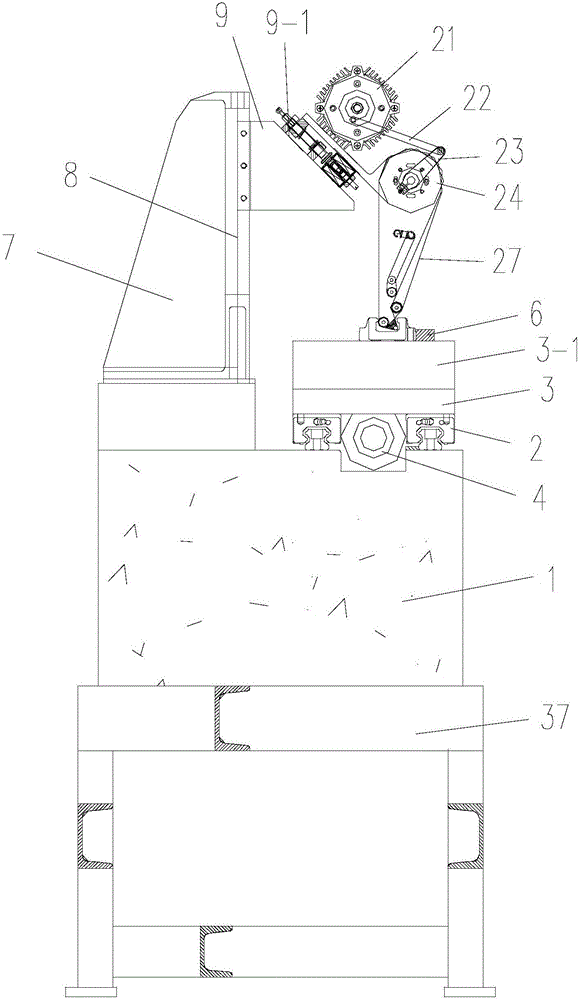

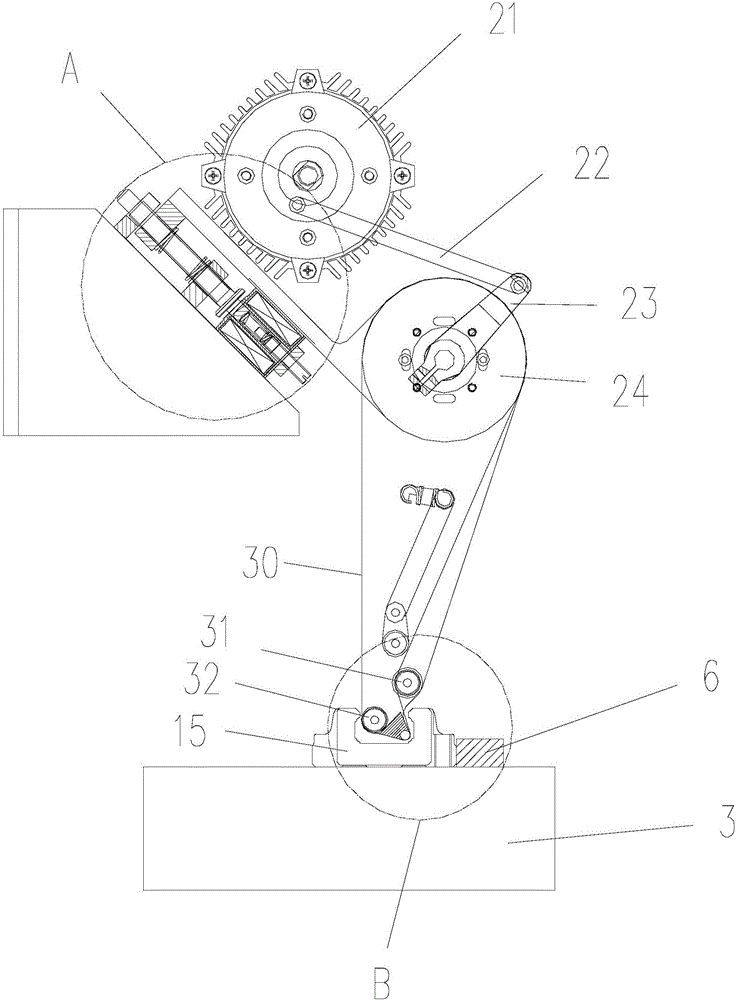

[0031]Referring to the accompanying drawings: the slider ultra-finishing machine in this embodiment includes a bed 1, the bed 1 is fixed on the frame 37, a transverse guide rail 2 is installed on the front of the bed 1, and a workbench 3 is installed on the transverse guide rail 2 The bed 1 is equipped with a screw 4 that drives the workbench 3 to slide and a servo motor 5 that drives the screw to rotate. The workbench 3 is equipped with an electro-permanent magnetic chuck 3-1, and the electro-permanent magnetic chuck 3-1 is equipped with a positioning plate 6. The rear part of the bed 1 is equipped with a superfinishing mechanism a for processing the inner raceway of the slider. The superfinishing mechanism a includes a fixing seat 7, and a longitudinal guide rail 8 is installed on the front end of the fixing seat 7. The longitudinal guide rail 8 The lifting seat 9 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com