Preparation method of multifunctional reinforced concrete corrosion inhibitor

A technology of reinforced concrete and corrosion inhibitor, applied in the field of reinforced concrete corrosion inhibitor, can solve the problem of less multifunctional corrosion inhibitor and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

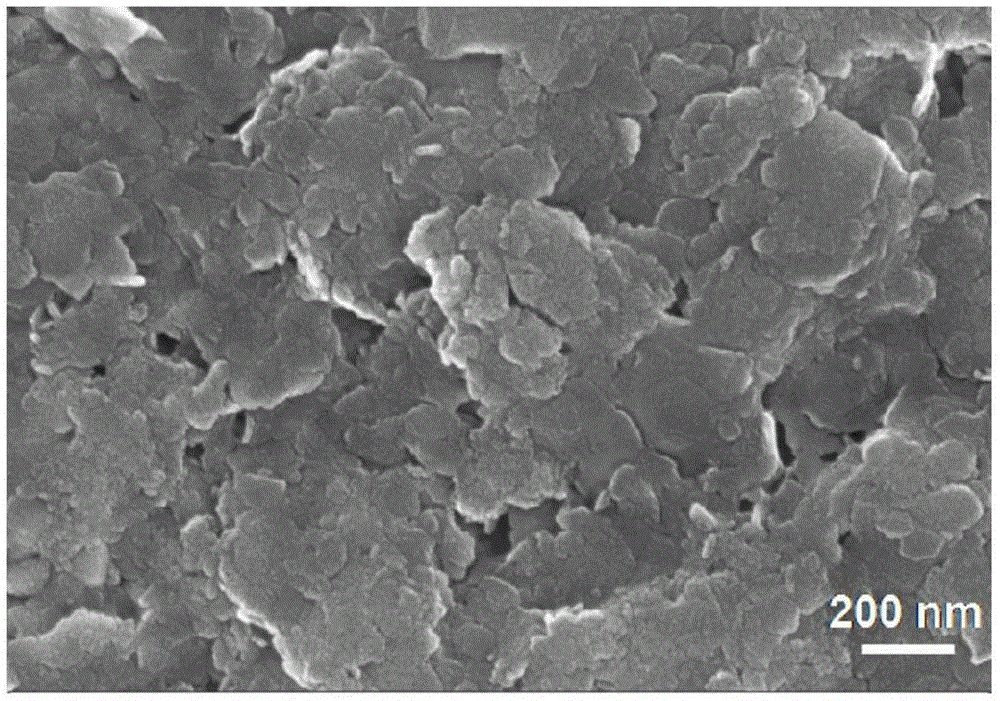

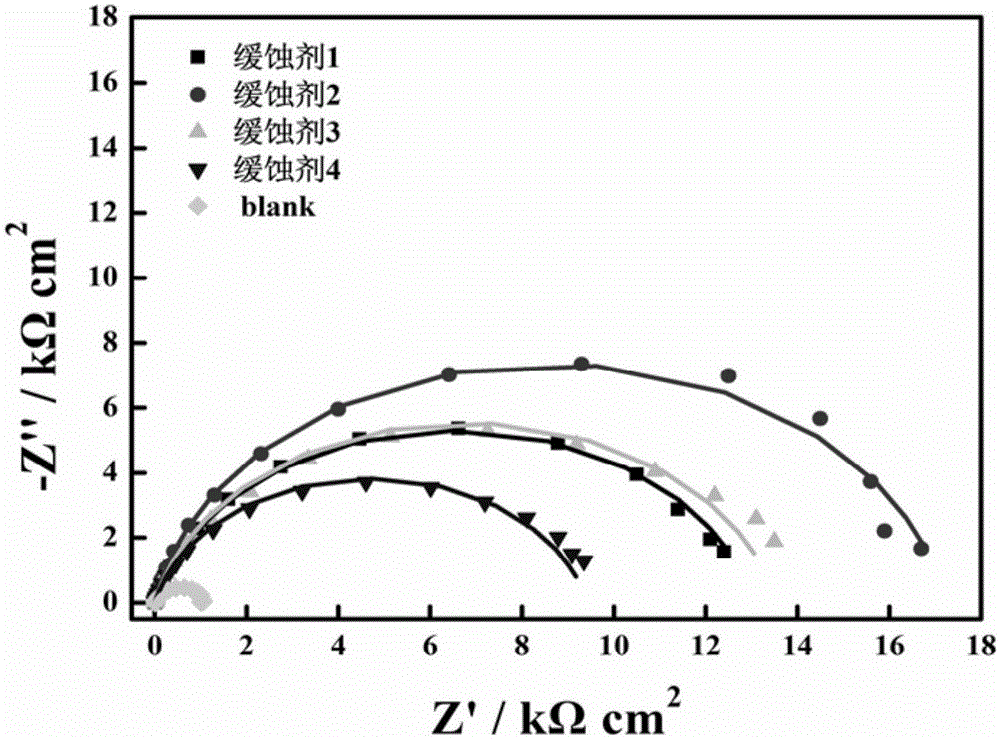

[0024] Example 1: Magnesium-aluminum double hydroxides (MgAl-LDHs) are selected as the precursor. The MgAl-LDHs were calcined at 500°C for 5h, and cooled naturally to room temperature to obtain magnesium aluminum oxides (MgAl-CLDHs). Disperse 0.5g of MgAl-CLDHs in 100mL of 0.1mol / L NaOH solution, stir vigorously at room temperature for 24h, and place the filtered solid product in 100mL of 0.5mol / L, pH 11 potassium hydrogen phthalate solution in the greenhouse. Under stirring for 24h. After filtering, the solid was dried in an oven at 70°C for 48 hours, and the dried product was ground into a powder in a mortar, which was labeled as corrosion inhibitor 1.

Embodiment 2

[0025] Example 2: Change the MgAl-CLDHs in Example 1 to 1 g, and the rest of the conditions are the same, marked as corrosion inhibitor 2.

Embodiment 3

[0026] Example 3: Change the MgAl-CLDHs in Example 1 to 3 g, and the rest of the conditions are the same, marked as corrosion inhibitor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com