Chemical grouting sealing device and method for underground formation sealing

An isolation device and grouting technology, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve the problem that the pressure bearing capacity cannot reach the ideal state, the material strength of the expansion cylinder is low, and the expansion agent is easily damaged. Decomposition and other problems, to achieve the effect of flexible site adaptability, good sealing adaptability, and large volume expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

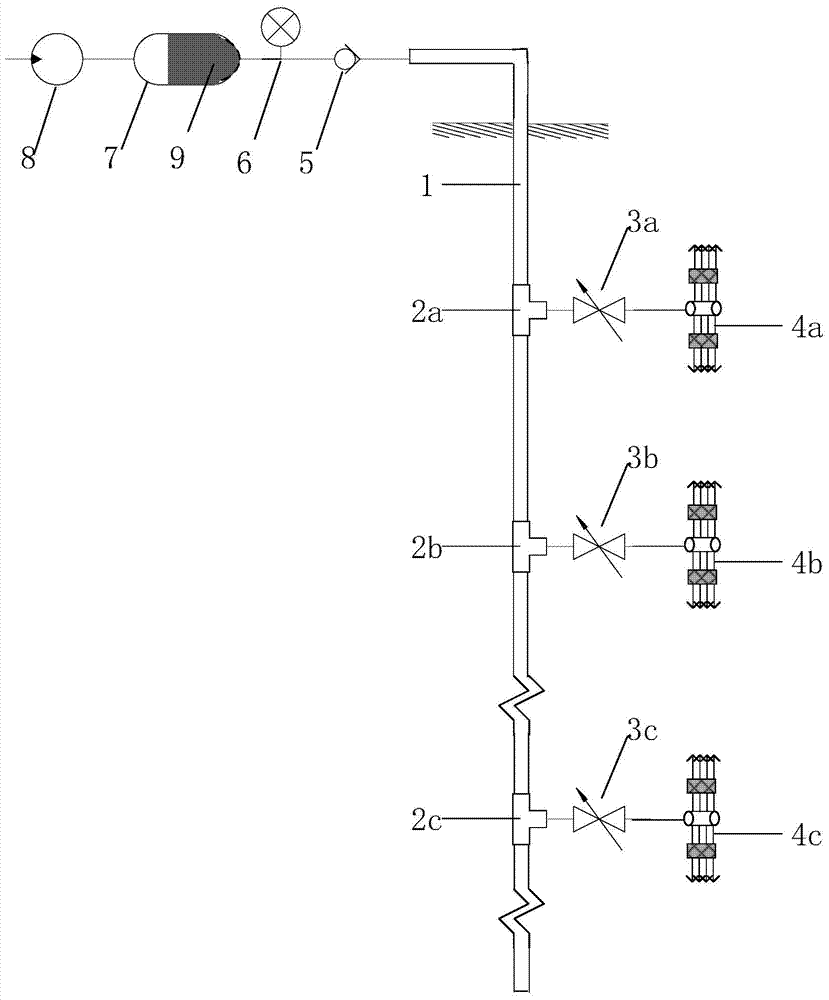

[0072] Such as figure 1 As shown, the chemical grouting isolation device suitable for downhole formation sealing of vertical wells includes a grouting pipe 1; a first tee 2a; a second tee 2b; a third tee 2c; Pressure control valve 3a; second self-operated sectional pressure control valve 3b; third self-operated sectional pressure control valve 3c; first spray plug 4a; second spray plug 4b; third spray plug 4c ; Throttle valve 5; Pressure gauge 6; Relay container 7; Manual pump 8; Chemical slurry 9.

[0073] The input end of the intermediate container 7 is provided with a manual pump 8, the output end of the intermediate container 7 is connected with the grouting pipe 1 through the throttle valve 5, and the output end of the intermediate container 7 is also provided with an output for detecting the intermediate container 7. The pressure gauge 6 of the terminal pressure, the grouting pipe 1 is vertically arranged underground, and the grouting plugs are installed at the position...

Embodiment 2

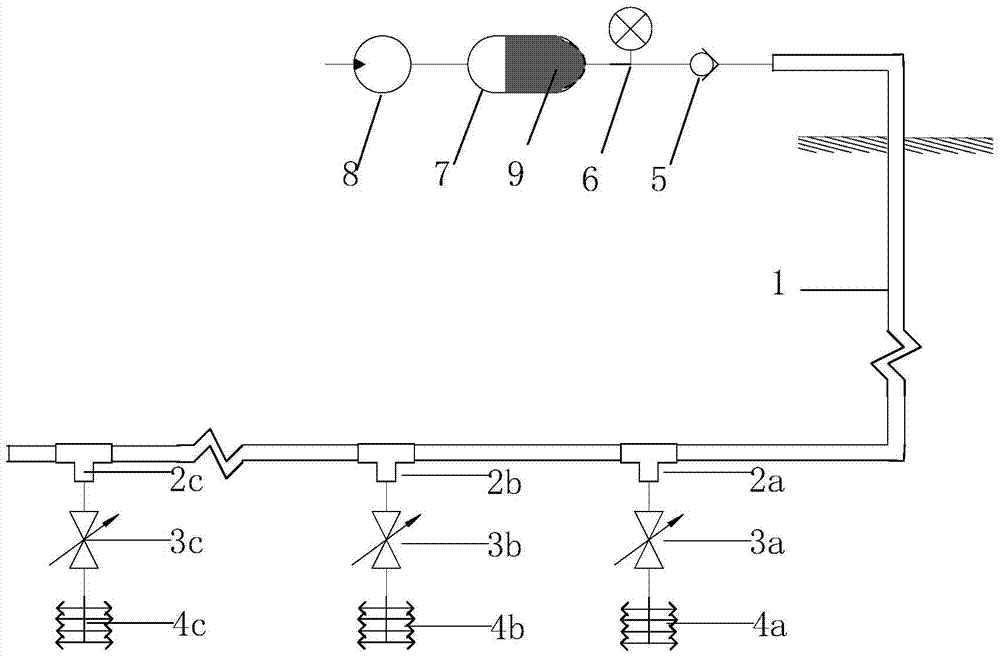

[0088] Such as figure 2 As shown, the chemical grouting isolation device suitable for downhole formation sealing of horizontal wells, including grouting pipe 1; first three-way 2a; second three-way 2b; third three-way 2c; Pressure control valve 3a; second self-operated sectional pressure control valve 3b; third self-operated sectional pressure control valve 3c; first spray plug 4a; second spray plug 4b; third spray plug 4c ; Throttle valve 5; Pressure gauge 6; Relay container 7; Manual pump 8; Chemical slurry 9.

[0089] The input end of the intermediate container 7 is provided with a manual pump 8, the output end of the intermediate container 7 is connected with the grouting pipe 1 through the throttle valve 5, and the output end of the intermediate container 7 is also provided with an output for detecting the intermediate container 7. The pressure gauge 6 of the end pressure, the grouting section of the grouting pipe 1 is set horizontally underground, and the grouting plug...

Embodiment 3

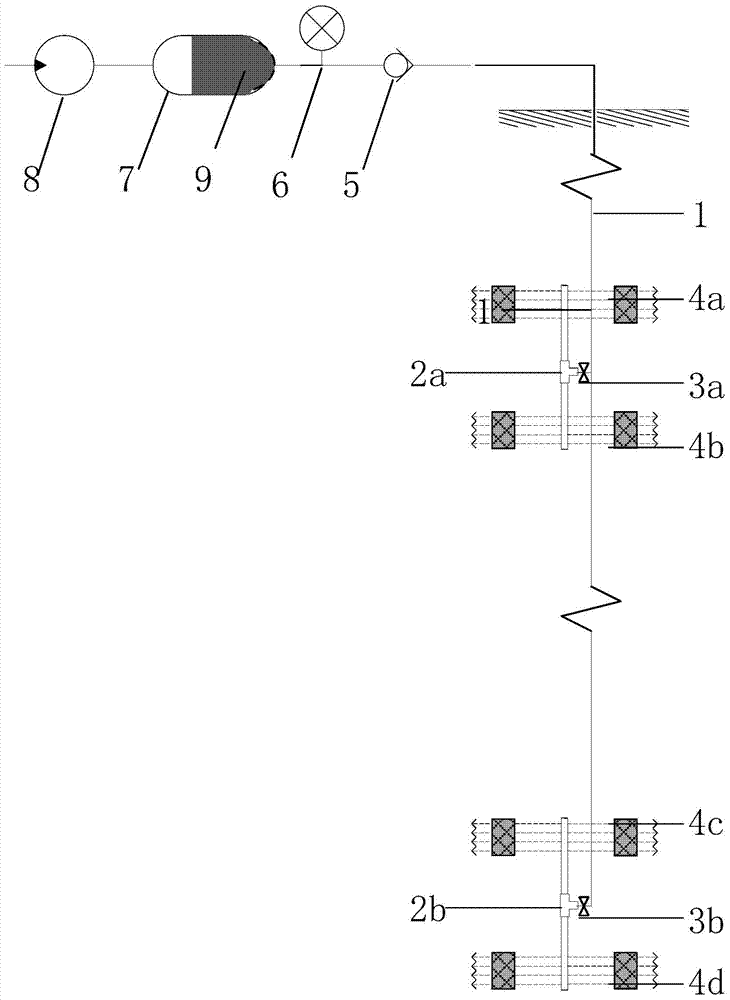

[0094] Such as image 3 As shown, the chemical grouting isolation device suitable for downhole formation sealing of vertical wells includes a grouting pipe 1; a first tee 2a; a second tee 2b; a third tee 2c; Pressure control valve 3a; second self-operated sectional pressure control valve 3b; third self-operated sectional pressure control valve 3c; first spray plug 4a; second spray plug 4b; third spray plug 4c ; Throttle valve 5; Pressure gauge 6; Relay container 7; Manual pump 8; Chemical slurry 9.

[0095] The input end of the intermediate container 7 is provided with a manual pump 8, the output end of the intermediate container 7 is connected with the grouting pipe 1 through the throttle valve 5, and the output end of the intermediate container 7 is also provided with an output for detecting the intermediate container 7. The pressure gauge 6 of the terminal pressure, the grouting pipe 1 is vertically arranged underground, and the grouting plugs are installed at the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com