75MVA transformer with mixed explosion-proof function

A technology of transformers and mixers, applied in transformer/inductor housing, transformer/inductor cooling, instruments, etc., to prevent secondary accidents, improve explosion-proof performance, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

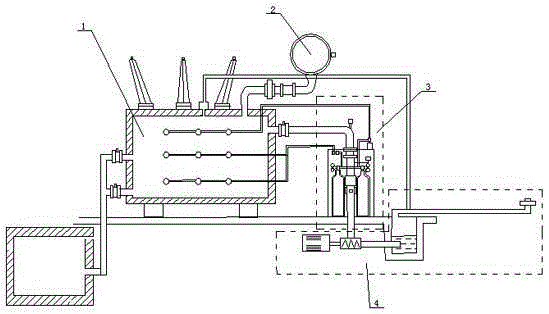

[0047] A hybrid explosion-proof 75MVA transformer of the present invention includes a fire extinguishing mechanism 3 connected to the transformer 1, a pressure release mechanism 4, a leak detection mechanism and a control mechanism;

[0048] Transformer 1, including shell, oil conservator 2, iron core, winding; oil conservator 2 is arranged on the upper end of the shell, and is connected with the shell through a pipeline, and the pipeline is provided with a gas relay and a shut-off valve; three-phase winding It is installed in the housing, and the winding is wrapped with an iron core. A temperature sensor is installed at the upper, middle and lower positions of the three-phase winding; a pressure sensor is respectively installed at the upper, middle and lower parts of the housing;

[0049] The fire extinguishing mechanism 3 includes a fire extinguishing box, a fire extinguishing tank, and a gas booster pump; the fire extinguishing tank is arranged in the fire extinguishing box,...

specific Embodiment 2

[0062] Transformer 1 unit, including shell, oil conservator 2, iron core, winding; oil conservator 2 is fixed on the top of the shell and connected to the shell through the gas relay and shut-off valve; the three-phase winding is set in the shell, each winding Wrapped with an iron core, a temperature sensor is installed at the upper, middle and lower positions of each winding; a pressure sensor is respectively installed at the upper, middle and lower parts of the casing to detect the oil temperature or gas temperature in the casing; the transformer There is a basement under 1;

[0063] The pressure release unit includes an oil discharge tank, an oil discharge pool, an oil discharge pump, an igniter, and a pressure release valve; the oil discharge tank is located in the basement below the transformer 1, and there is a solenoid valve on the middle and lower outside of the transformer 1 housing, The two solenoid valves are connected in parallel to the oil discharge tank; an oil d...

specific Embodiment 3

[0073] (3) Open the solenoid valve at the outlet of the mixer, so that the air pressure in the pipeline connecting the mixer and transformer 1 rises to 15-18kpa, then close the solenoid valve, and the air pressure in the mixer drops to 30-35kpa;

[0074] (4) The control unit opens or closes the helium tank, the heptafluoropropane tank, and the nitrogen tank in turn until the pressure in the mixer reaches 80kpa, and makes the content ratio in the mixer helium: heptafluoropropane: nitrogen = (8.5-9.4): (4.6 -5.3): (11.3-15.2); then continue to open or close the helium tank, heptafluoropropane tank, and nitrogen tank in sequence according to the ratio until the pressure in the mixer is 100±10%kpa;

[0075] (5) When the pressure in the helium tank, nitrogen tank, and heptafluoropropane drops to 15%-20% of its initial pressure, it should be replenished in time.

[0076] Due to the above method, the use of a mixed fire extinguishing gas can avoid unnecessary losses caused by a singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com