Centrifuging device

A centrifugal device and tooling technology, which is applied in the field of membrane separation, can solve problems such as flying glue, rising scrap rate, and easy falling off of connection parts, and achieve the effects of improving the strength and quality of end seals, avoiding the existence of air bubbles, and avoiding the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the centrifuge device of the embodiment of the present invention is described in further detail:

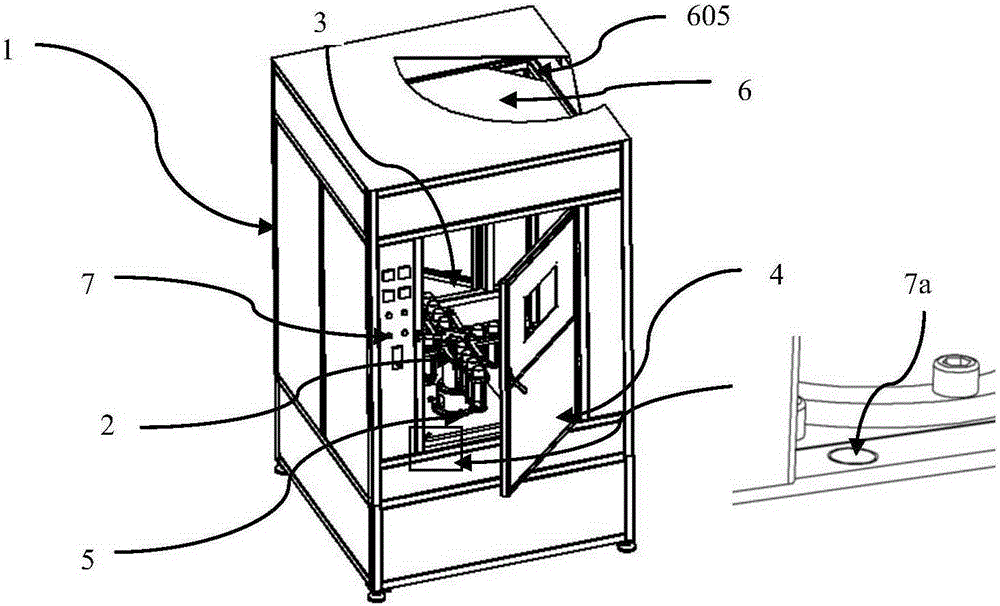

[0037] Centrifugal device of the present invention, such as figure 1 As shown, it is mainly composed of a frame 1 and an operation door 4; the structure in the frame 1 includes a rotor 2, a rotating chamber 3, a rotary drive mechanism 5, a hot air circulation part 6 and a control device 7; the frame 1 is provided with a fixed rotary drive The support position of the mechanism 5 and the support position of the fixed hot air circulation part 6; the operation door 4 is connected to the frame 1 by means of side hinges, and its position is set on two opposite sides of the frame 1 for covering the rotating Chamber 3, thereby forming a closed rotating space, and an observation window is provided on the operation door 4, which is convenient for observing the operation conditions in the rotating chamber 3.

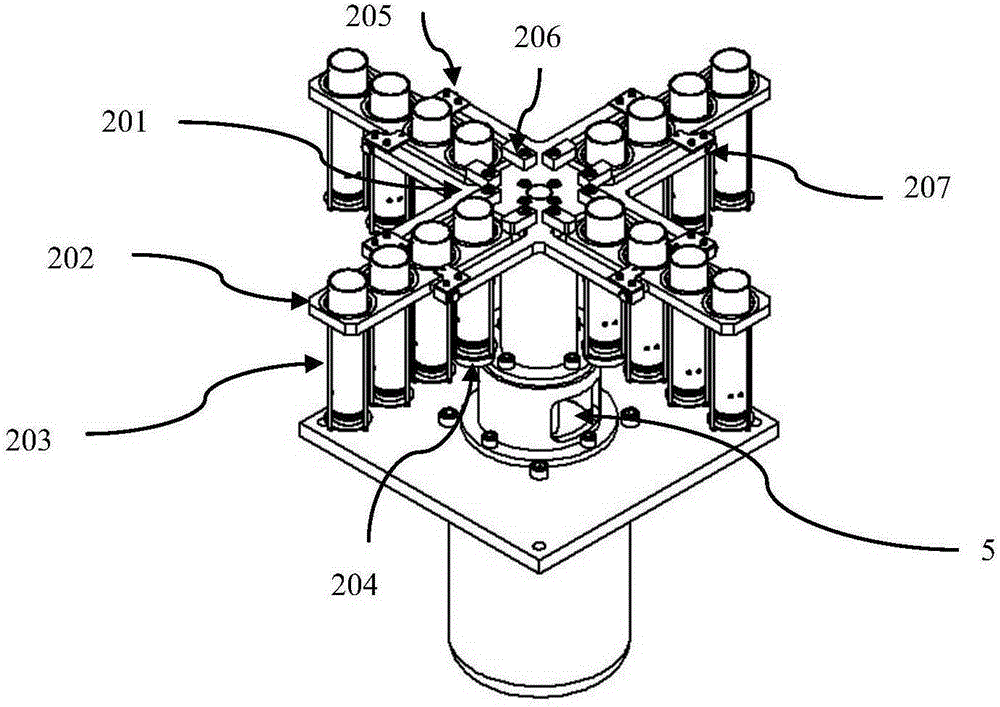

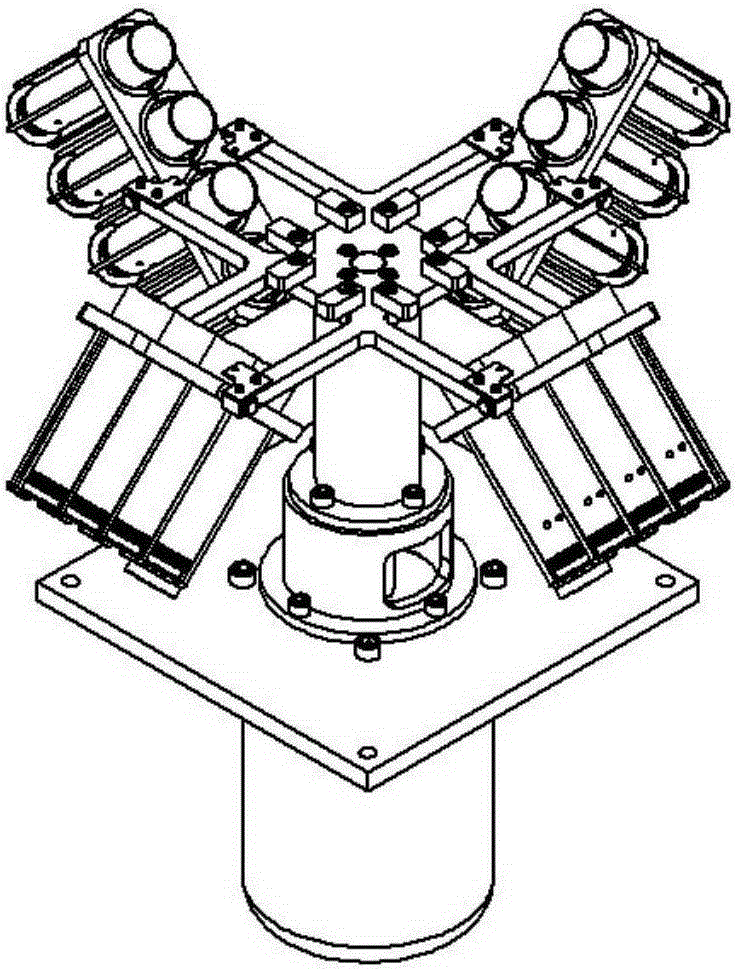

[0038] Wherein the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com