Method for reducing electrode vibration amplitude of tubular electrode during electrolytic machining

An electrode and amplitude technology, applied in the field of electrolytic machining of tube electrodes, can solve problems such as difficult control, uneven fluid stress, small diameter, etc., to increase the surface of the workpiece to be ground, improve the roughness and machining accuracy, and reduce the abrasive particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

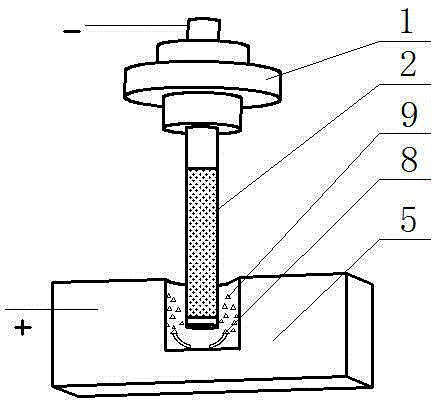

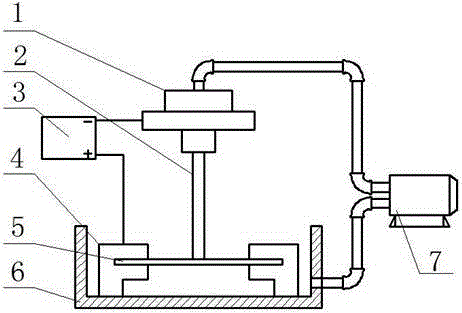

[0017] Such as figure 1 , 2 As shown, it includes: the clamping and sealing device 1 of the electrolytic processing machine tool, which is responsible for the clamping of the tube electrode and the sealing of the electrolyte; the tube electrode 2 is perforated and insulated on the side, and the upper end is connected to the clamping and sealing device 1 of the electrolytic processing machine tool , and connected to the negative electrode of the processing power supply as the cathode of the electrolytic processing, and spray the electrolyte downward during processing; the processing power supply 3 provides the required DC power during processing; the workpiece fixture 4 is responsible for clamping and fixing the workpiece; the workpiece 5 is connected to the positive electrode of the processing power supply 3 An anode for electrolytic machining; an electrolytic cell 6, which provides an electrolyte processing environment for electrolytic machining; an electrolyte circulation pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com