A method for extracting Glauber's salt and industrial salt from high-salt wastewater

A high-salt wastewater and industrial salt technology, applied in chemical instruments and methods, alkali metal sulfite/sulfite, alkali metal chloride, etc., can solve the problems of inability to obtain qualified nitrate or salt industrial products, restrictions on implementation, and non-compliance It is possible to realize the separation of nitrate and salt, and achieve the effect of high reuse rate, high recovery rate, low COD and NH3-N

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

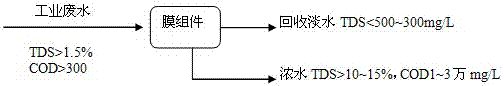

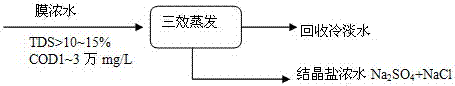

Method used

Image

Examples

Embodiment 1

[0060] Utilize the treatment method of the present invention to process high-nitrate and low-salt wastewater:

[0061] This is high-salt wastewater after extreme concentration by nanofiltration membrane, and its characteristics are:

[0062] Glauber's salt (Na 2 SO 4 ) 80g / L; salt (NaCl) 20g / L; total salt TDS 100g / L;

[0063] The proportion of nitrate in total salt TDS: nitrate>80%, salt<20%, and the ratio of nitrate to salt is less than 1:0.25.

[0064] The present invention is as follows to the treatment step of above-mentioned waste water:

[0065] Step 1: Oxidation: with H 2 SO 4 Adjust the pH of the wastewater to 3 while adding FeSO 4 and a concentration of 30% H 2 o 2 , reaction for 2 hours, FeSO 4 The addition amount is 500 mg / L, and the oxidation-reduction potential value is controlled at ORP500mv to remove organic pollutants in wastewater.

[0066] Step 2: Softening: Add 30% NaOH and 70% Na 2 CO 3 Adjust the pH value of the wastewater to 9, and at the same...

Embodiment 2

[0073] Utilize the treatment method of the present invention to process high-nitrate and low-salt wastewater:

[0074] This is high-salt wastewater after extreme concentration by nanofiltration membrane, and its characteristics are:

[0075] Glauber's salt (Na 2 SO 4 ) 120g / L; salt (NaCl) 30g / L; total salt TDS 150g / L;

[0076] The proportion of nitrate in total salt TDS: nitrate>80%, salt<20%, and the ratio of nitrate to salt is less than 1:0.25.

[0077] The present invention is as follows to the treatment step of above-mentioned waste water:

[0078] Step 1: Oxidation: with H 2 SO 4 Adjust the pH of the wastewater to 3 while adding FeSO 4 and a concentration of 30% H 2 o 2 , reaction for 2 hours, FeSO 4 The addition amount is 500 mg / L, and the oxidation-reduction potential value is controlled at ORP600mv to remove organic pollutants in wastewater.

[0079] Step 2: Softening: Add 30% NaOH and 70% Na 2 CO 3 Adjust the pH value of the wastewater to 9, and at the sam...

Embodiment 3

[0086] Utilize the treatment method of the present invention to process high-salt and low-nitrate wastewater:

[0087] The salt mining brine of the salt mine is re-concentrated in the primary mother liquor, and the secondary mother liquor after freezing and out of stock is all high-salt and low-nitrification wastewater. The characteristics are:

[0088] Salt (NaCl) 200g / L; Nitrate (NaCl) 2 SO 4 ) 20g / L; total salt TDS 220g / L;

[0089] The proportion of nitrate in total salt TDS: nitrate 90%, and the ratio of nitrate to salt is higher than 1:9.

[0090] The present invention is as follows to the treatment step of above-mentioned waste water:

[0091] Step 1: Oxidation: with H 2 SO 4 Adjust the pH of the wastewater to 5 while adding FeSO 4 and a concentration of 30% H 2 o 2 , reaction for 1 hour, FeSO 4 The addition amount is 800mg / L, and the oxidation-reduction potential value is controlled at ORP800mv to remove organic pollutants in wastewater.

[0092] Step 2: Softe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com