Compound mortar with compound addition of carbon fibers and nano-silica and preparation technology and application thereof

A technology of nano-silica and composite mortar, applied in the field of building materials, can solve problems such as large discreteness, and achieve the effect of small discreteness of resistivity, improved compressive strength, and promotion of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

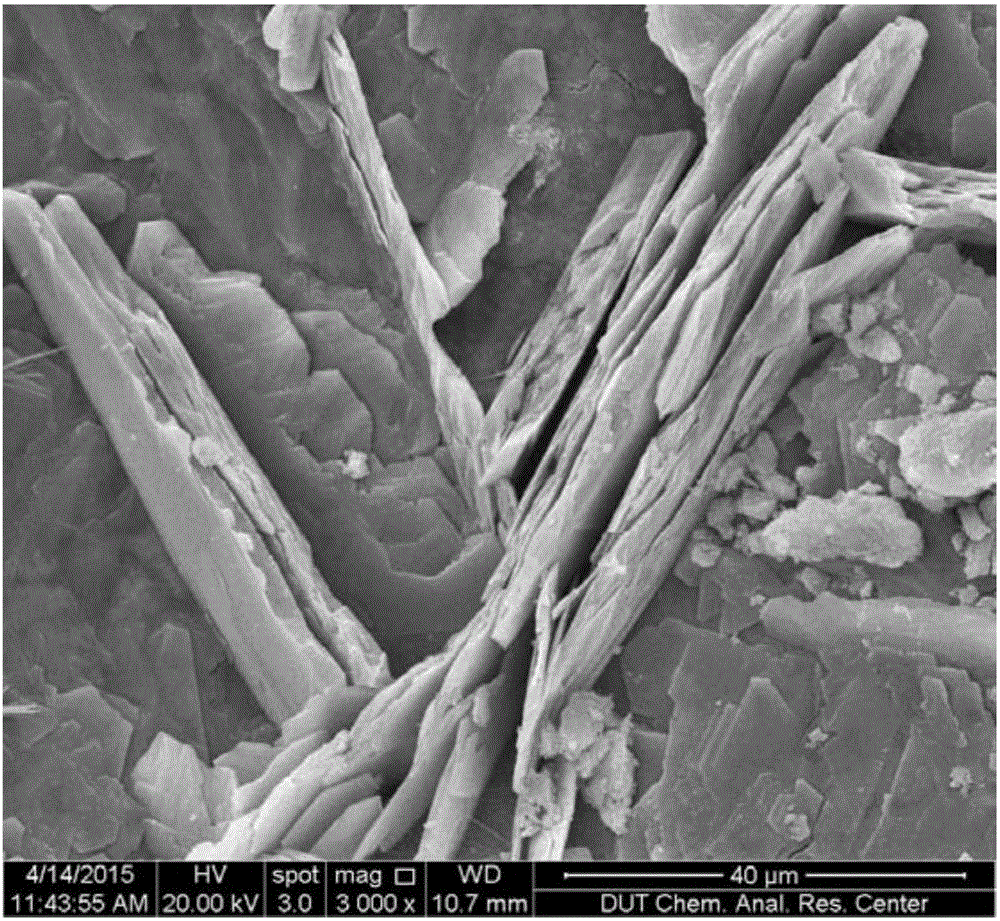

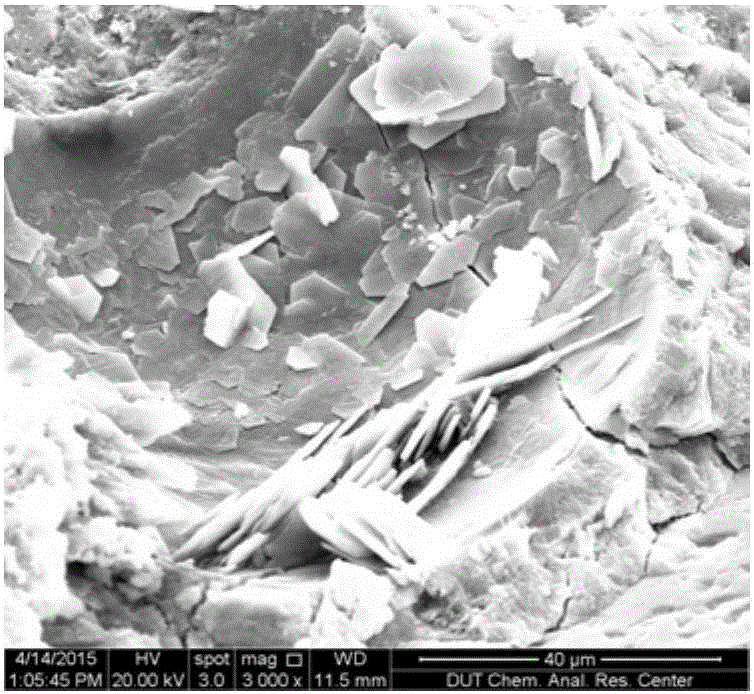

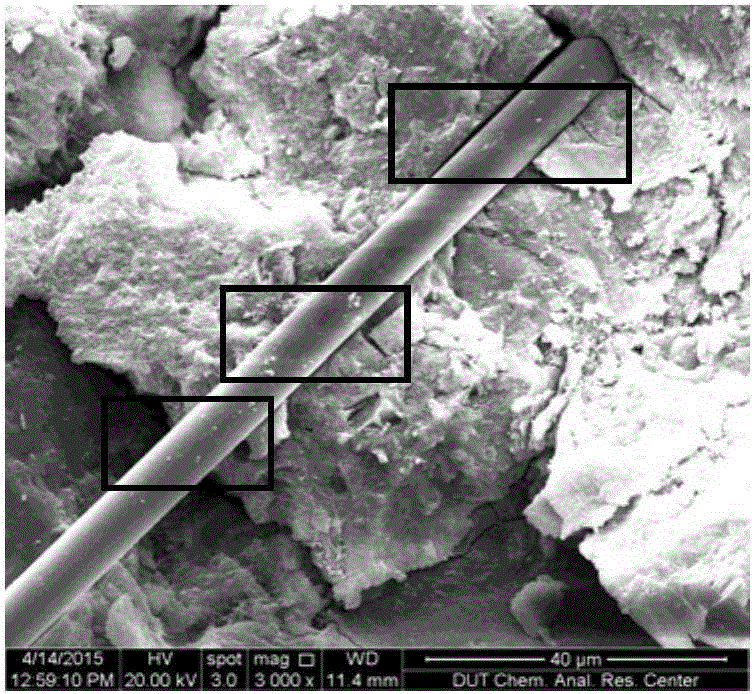

Image

Examples

Embodiment 1-3

[0029] Embodiment 1-3 composite mortar mixed with carbon fiber and nano silicon dioxide

[0030] Table 1 raw material weight ratio ratio

[0031]

[0032] (1) Take the raw materials in the ratio described in Table 1; add water, water reducing agent, carbon fiber and nano-silica to the container, stir evenly, and ultrasonicate at 25°C for 30 minutes to obtain a mixture, and cool it to room temperature; then Add the mixture, cement, and standard sand into the cement mortar mixing pot, and stir evenly to obtain the mixture;

[0033] (2) pour the mixture into a mold (40mm×40mm×160mm), then place the mold on a vibrating table and vibrate for 20 seconds;

[0034] (3) According to the size of the mixture in the mold, insert electrodes for connecting external circuits (such as Figure 4 shown), vibrate for 10 seconds;

[0035] (4) Put the mold into the curing box, maintain it for 24 hours at a temperature of 20±1°C and a humidity greater than 95%, and then remove the mold to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com