System for dragging converter flue gas induced draft fan by aid of converter steam

A converter flue gas and induced draft fan technology, which is applied to furnaces, furnace components, manufacturing converters, etc., can solve the problems of the hybrid driving technology, such as the lack of a steam stabilizing device, the reduction of life, and the low power of the waste heat generator set. Quality and functional ability, improve utilization efficiency, and stabilize the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

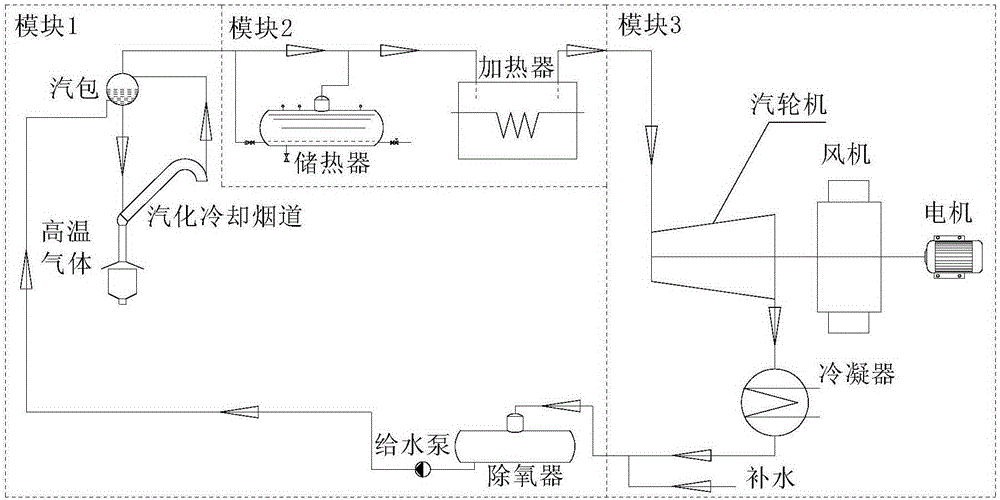

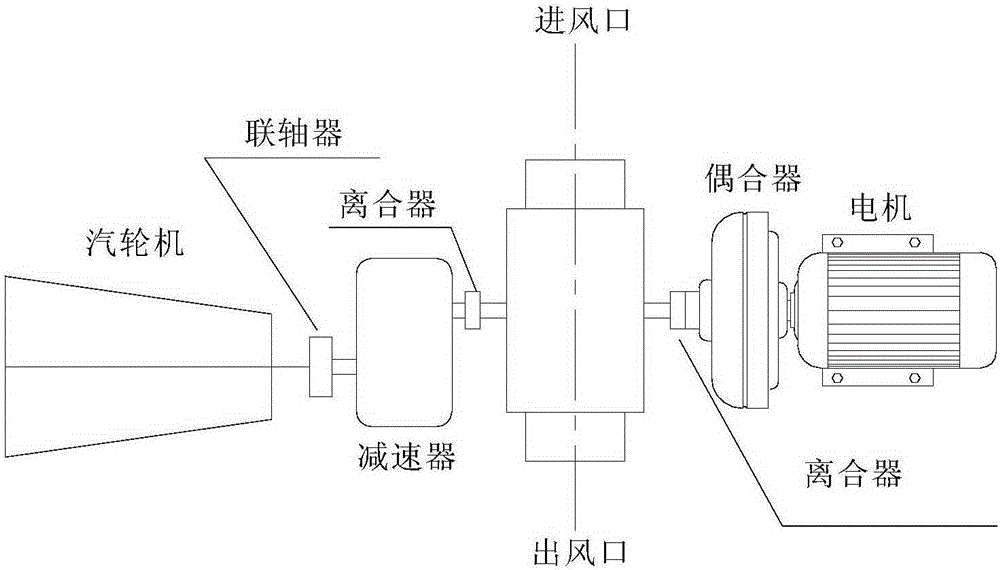

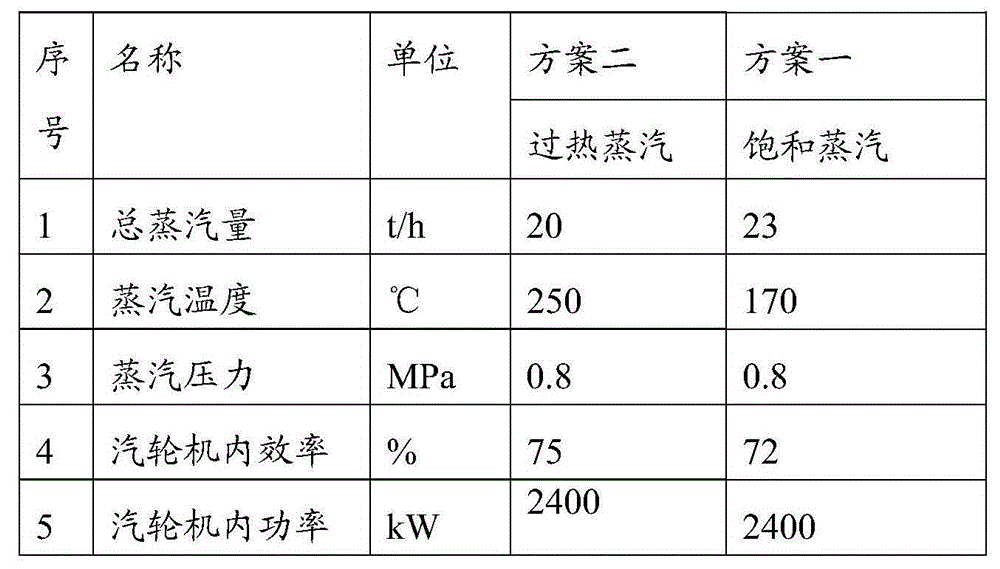

[0011] Such as Figure 1-2 As shown, the system using converter steam to drive the converter flue gas induced draft fan includes a waste heat boiler unit, a converter flue gas induced draft fan, and the system also includes a steam heat storage and steady flow unit and a steam turbine unit; Boilers, steam drums, deaerators, and the cooling water in the converter vaporization cooling flue are heated to produce medium and low pressure steam, which is collected in the steam drum and saturated steam is generated through the pressure-controlled exhaust valve; the steam heat storage and steady flow unit includes a heat storage device , control valve, heat storage to store saturated steam and ensure a stable steam flow; the steam turbine unit includes a steam turbine, a condenser, a condensate pump, a seal heater, and a low-temperature heater. The water is condensed into water by the condensate pump, pressurized by the condensate pump, passes through the steam seal heater, the low te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com