Al-Ni-Y-Ca aluminum-based amorphous alloy and preparation method thereof

An al-ni-y-ca, amorphous alloy technology, applied in the field of amorphous alloys, can solve the problems of high price, high cost, unsuitable for industrial production, etc., achieve low cost, increase melt bulk density, Effect of suppressing the diffusion of Al atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: prepare Al 84.5 Ni 7 Y 8 Ca 0.5 amorphous alloy

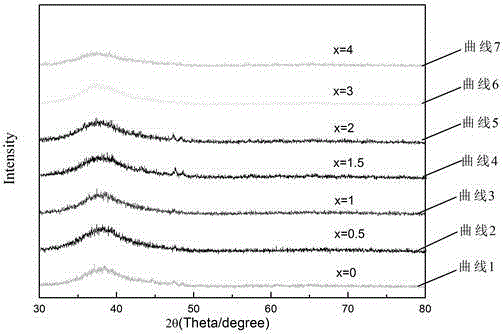

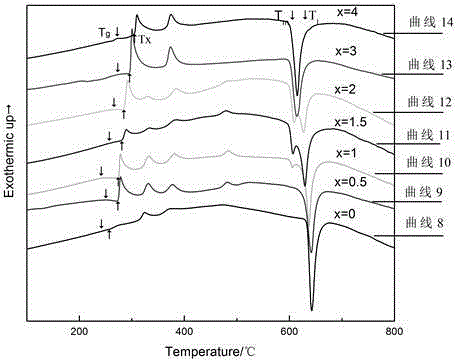

[0049] Al by nominal composition 84.5 Ni 7 Y 8 Ca 0.5 (Al 85-x Ni 7 Y 8 Ca x (x=0.5)) for batching, using the experimental steps and conditions of the comparative example to prepare the composition of Al 84.5 Ni 7 Y 8 Ca 0.5 The alloy thin strip, the vacuum degree is 2Pa; X-ray diffraction (XRD) for phase analysis, the results show that the alloy thin strip has an amorphous structure, see attached figure 1 Curve 2; differential scanning calorimetry (DSC) for thermal stability analysis, the results show that Al 84.5 Ni 7 Y 8 Ca 0.5 T of amorphous ribbon g and T x 523K, 547K, see attached figure 2 Curve 9, than Al 85 Ni 7 Y 8 Improve 10K, 17K; the parameter ΔT that characterizes the ability of amorphous formation x 24K, than Al 85 Ni 7 Y 8 Increased by 41.2%.

Embodiment 2

[0050] Embodiment 2: prepare Al 84 Ni 7 Y 8 Ca 1 amorphous alloy

[0051] Al by nominal composition 84 Ni 7 Y 8 Ca 1 (Al 85-x Ni 7 Y 8 Ca x (x=1)) for batching, using the experimental steps and conditions of the comparative example to prepare the composition of Al 84 Ni 7 Y 8 Ca 1 The alloy thin strip, the vacuum degree is 1Pa; X-ray diffraction (XRD) for phase analysis, the results show that the alloy thin strip has an amorphous structure, see attached figure 1 Curve 3; differential scanning calorimetry (DSC) for thermal stability analysis, the results show that Al 84 Ni 7 Y 8 Ca 1 T of amorphous ribbon g and T x 518K, 548K, see attached figure 2 Curve 10, compared to Al 85 Ni 7 Y 8 Improvement of 5K, 18K; parameter ΔT characterizing the ability of amorphous formation x 32K, than Al 85 Ni 7 Y 8 An increase of 88.2%.

Embodiment 3

[0052] Embodiment 3: prepare Al 83.5 Ni 7 Y 8 Ca 1.5 amorphous alloy

[0053] Al by nominal composition 83.5 Ni 7 Y 8 Ca 1.5 (Al 85-x Ni 7 Y 8 Ca x (x=1.5)) for batching, using the experimental steps and conditions of the comparative example to prepare the composition of Al 83.5 Ni 7 Y 8 Ca 1.5 The alloy thin strip, the vacuum degree is 0.5Pa; X-ray diffraction (XRD) for phase analysis, the results show that the alloy thin strip has an amorphous structure, see attached figure 1 Curve 4; differential scanning calorimetry (DSC) for thermal stability analysis, the results show that Al 83.5 Ni 7 Y 8 Ca 1.5 T of amorphous ribbon g and T x 529K, 555K, see attached figure 2 Curve 11, ratio Al 85 Ni 7 Y 8 Improve 16K, 25K; the parameter ΔT that characterizes the ability of amorphous formation x 26K, than Al 85 Ni 7 Y 8 Increased by 52.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com