Method for water-stopping grouting plugging in high-pressure high-flow water gush channel

A high-flow, water-gushing technology, which is used in earth-moving drilling, sealing/packaging, wellbore/well components, etc., can solve the problems of high-pressure and large-flow water inrush, difficult to control construction quality, and borehole blockage. Achieve the effect of improving plugging efficiency, saving engineering economy and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

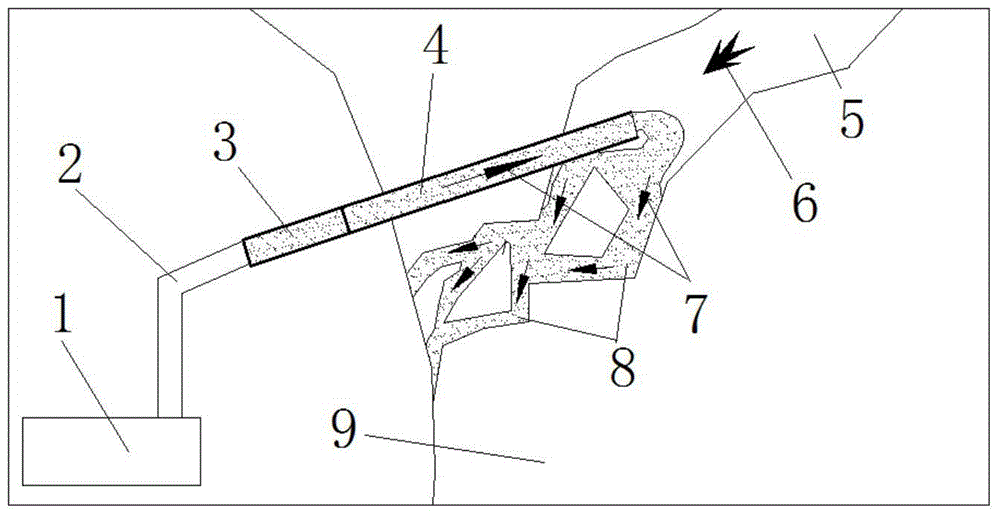

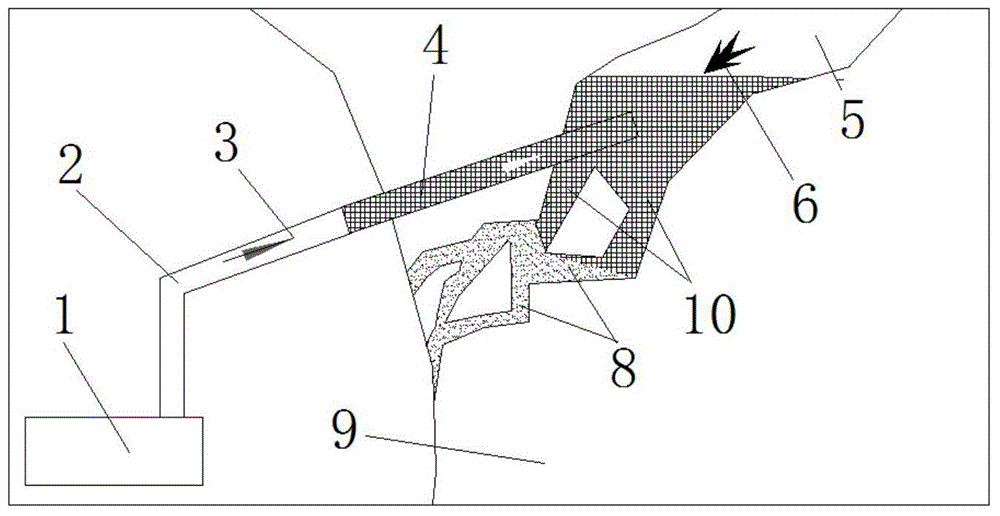

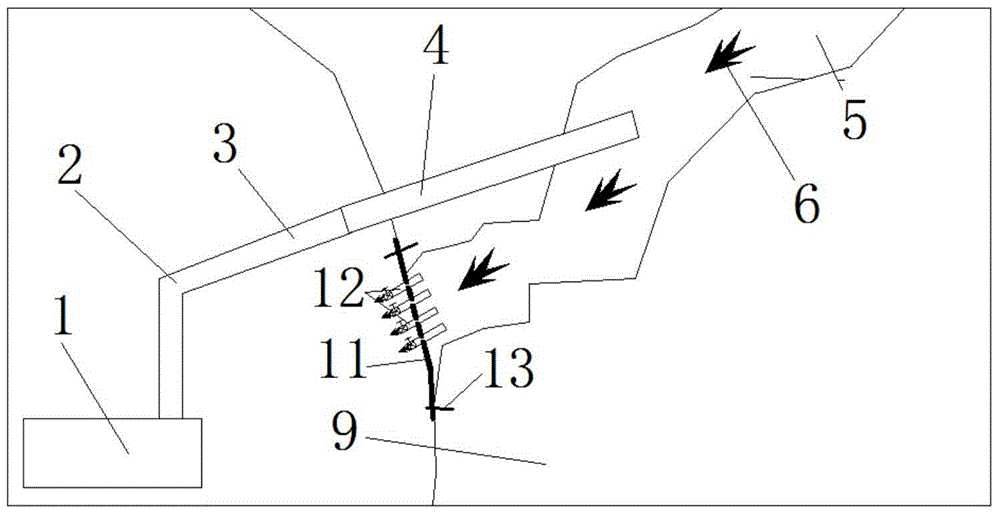

Method used

Image

Examples

Embodiment

[0061] Shandong Xinjulong Energy Co., Ltd. is a super-large mine with an annual output of 6 million t / a, which is a national key construction project during the Tenth Five-Year Plan, developed and constructed by Xinwen Mining Group Corporation. The initial mining level of the mine is -810m, the ground elevation is +43.6m, the buried depth is large, the surface soil is thick, and the fault structure is extremely developed. The second auxiliary transportation roadway of the mine passes through multiple rock formations, and the water gushing is serious. The water gushing is mainly located in the layers of limestone, mudstone, argillaceous fine sandstone, siltstone, and fine sandstone. The two tensional faults FL8-1 and FL8-2 in the area cut off the three-ash aquifer and provided a vertical channel for groundwater circulation, which intensified the migration and discharge of karst water. The initial exposure pressure of water gushing in the roadway is 7.5MPa, and the water pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com