Device for using refrigerator compressor heat temperature difference for generating electricity and cooling

A refrigerator compressor and thermoelectric power generation technology, which is applied to household refrigeration devices, applications, machines/engines, etc., to achieve the effects of easy installation and maintenance, convenient processing, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

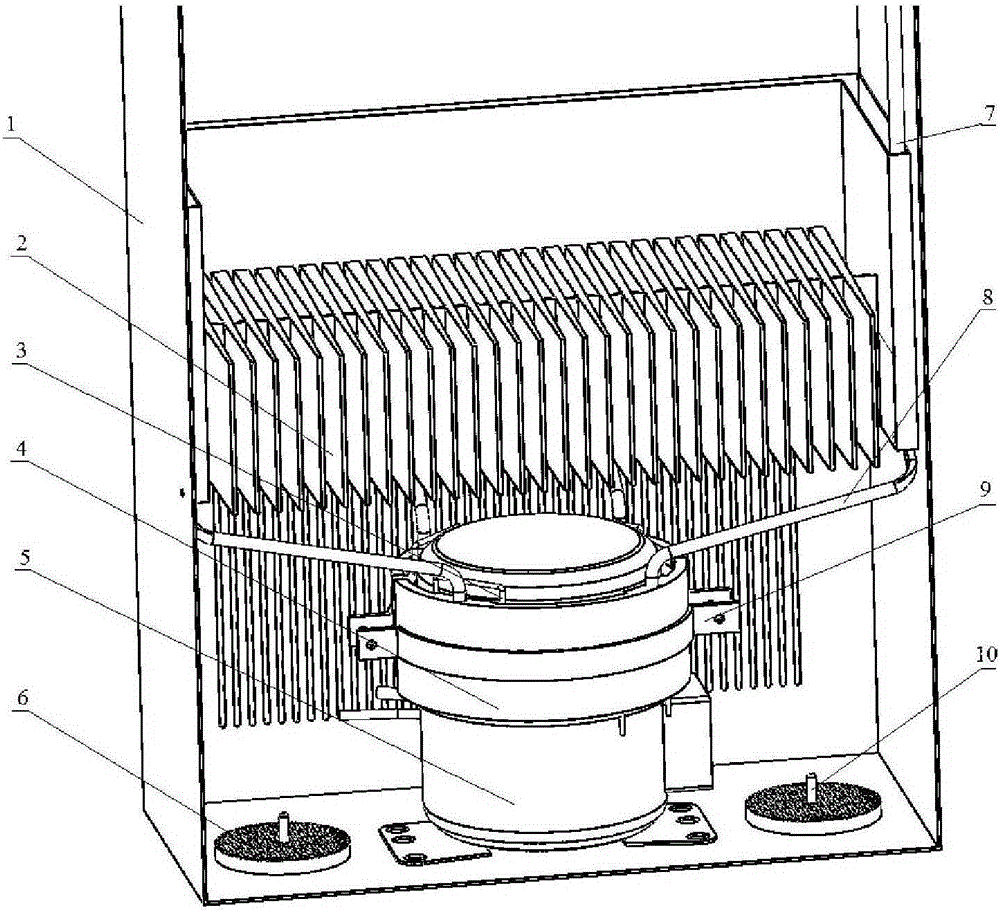

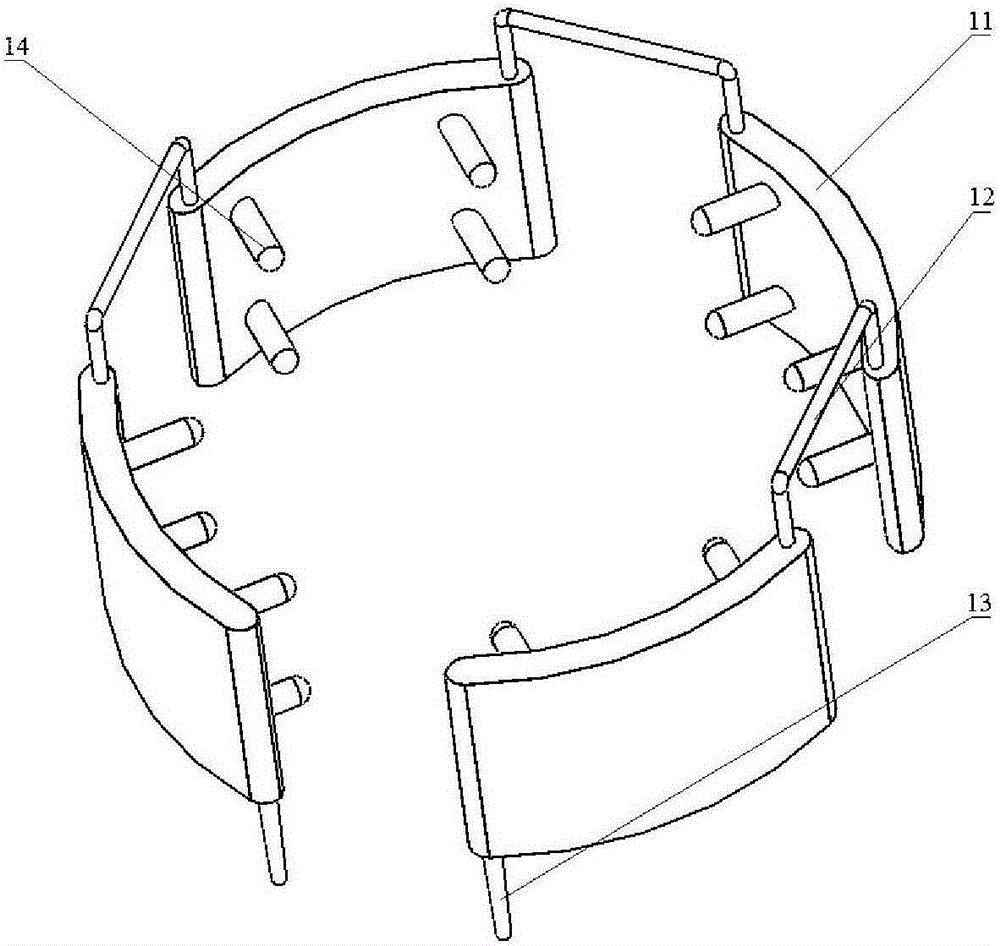

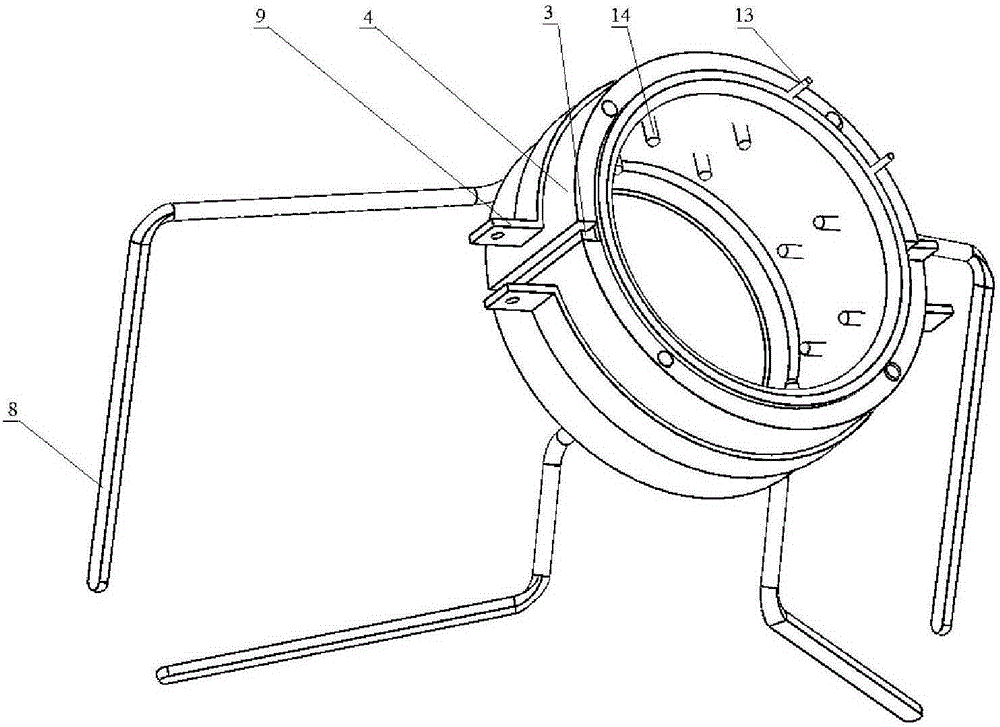

[0037] Such as figure 1 As shown in the figure, a device for generating electricity and cooling by using the temperature difference of the heat of a refrigerator compressor includes a short heat pipe 14, a semiconductor thermoelectric power generation sheet module 3, a soaking plate 4, a long heat pipe 8, a heat dissipation aluminum plate 2, a condensate water conduit 7, and a filter screen 6 and fan 15; the semiconductor thermoelectric power generation sheet module 3 is composed of a plurality of semiconductor thermoelectric power generation sheets 11 connected to form an annular shape, which tightly surrounds the refrigerator compressor 5 shell; the soaking plate 4 is installed on the semiconductor thermoelectric power generation sheet module 3 on the outer periphery of the refrigerator compressor 5; evenly drilled with a plurality of (such as 16) through holes on the circumference of the refrigerator compressor 5; the semiconductor thermoelectric power generation sheet modul...

Embodiment 2

[0048] Such as figure 1 As shown in the figure, a device for cooling and cooling by using the temperature difference of the heat of the refrigerator compressor, including a refrigerator compressor 5, a short heat pipe 14, a semiconductor thermoelectric power generation sheet module 3, an aluminum sleeve 4, a tightening ring 9, a long heat pipe 8, and a heat dissipation aluminum plate 2 , condensed water conduit 7, filter screen 6 and fan 15; 16 through holes are drilled on the circumference of the refrigerator compressor 5 shells; one end of the short heat pipe 14 is inserted into the through hole of the refrigerator compressor 5; the other end of the short heat pipe 14 is embedded in In the hot end groove of the semiconductor thermoelectric power generation chip 11, the hot end groove of the semiconductor thermoelectric power generation chip 11 is hemispherical in diameter; Surrounding the refrigerator compressor 5 casing; the cold end of the semiconductor thermoelectric powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com