Energy-saving drive device for low-voltage electromagnetic type electric appliance

A driving device and electromagnetic technology, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve problems that do not conform to the control habits of low-voltage electromagnetic electrical appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

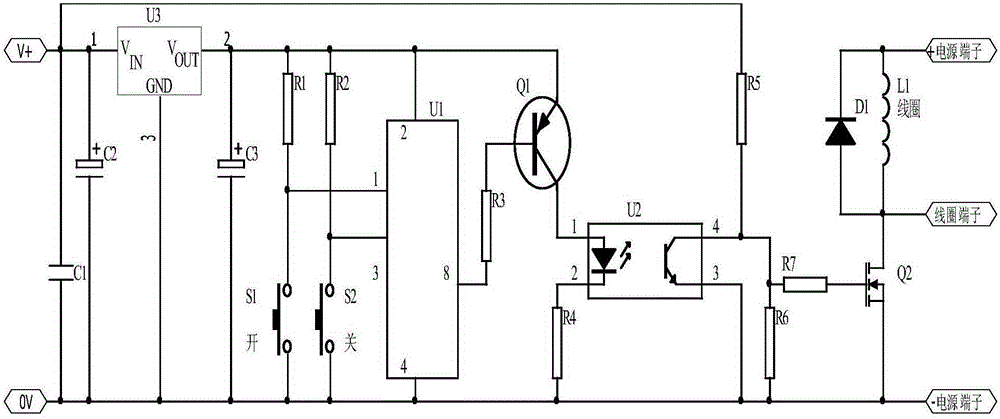

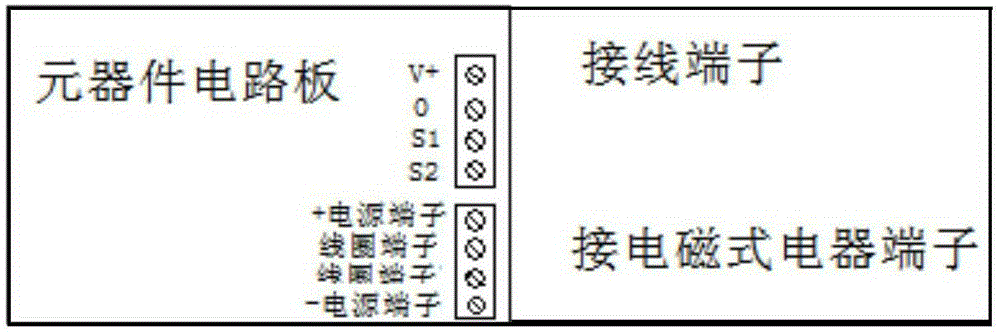

[0011] The energy-saving driving device of the low-voltage electromagnetic electric appliance of the present invention adopts a hardware single-chip microcomputer (mcu), a DC power supply, a triode, a high-power field effect tube, a resistor, a capacitor, a terminal block and a PWM program, and is characterized in that the PWM technology is used to simulate the signal. The level is digitally coded, and the duty cycle is changed through program control pulse width modulation. The power-saving driver program is stored in the single-chip microcomputer and connected between the power supply, start and stop signal input terminals and the solenoid valve coil; see figure 1 , the connection of the energy-saving drive circuit containing the program: the ground terminal 3 pin of the three-terminal voltage regulator U3 and the 4 pin of the single chip microcomputer U1, the anti-interference capacitor C1, the negative pole of the first filter capacitor C2 and the second filter capacitor C3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com