Dynamic characteristic testing device and method for vehicle transmission system dynamic vibration absorber

A technology of dynamic shock absorber and transmission system, which is applied in the test of vehicle suspension/shock absorbing mechanism, etc., which can solve the problem that it is difficult to separate the dynamic response characteristics of the drive shaft from the test results, which affects the design and development cycle and cost of automobile products, and the vehicle road test verification effect is obtained. No problems such as guarantees can be achieved, and the effect of solving the problems of positive matching design and adjustment control, shortening the vehicle development cycle, and shortening the engineering development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

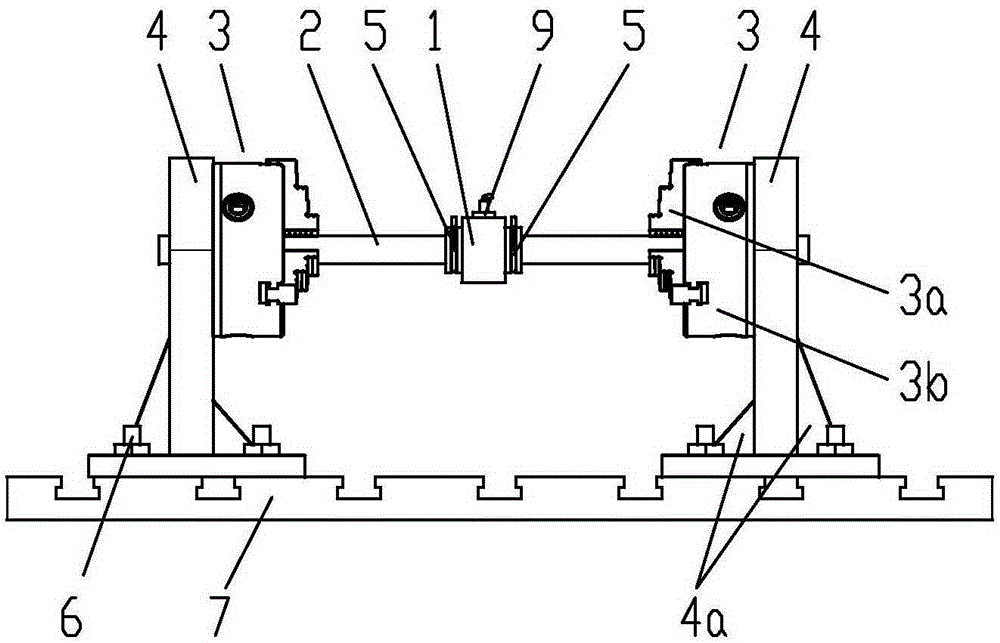

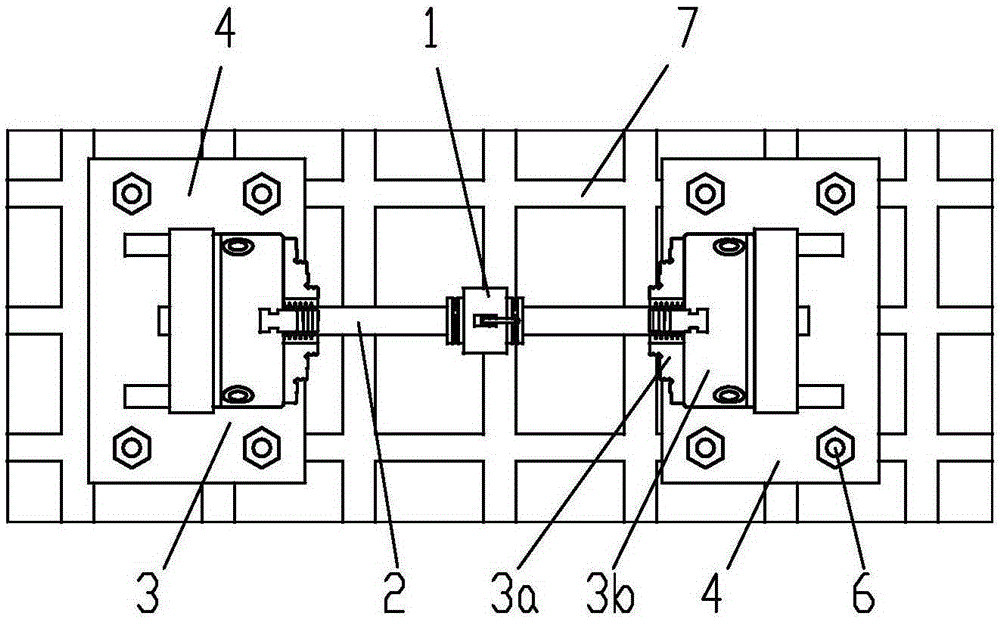

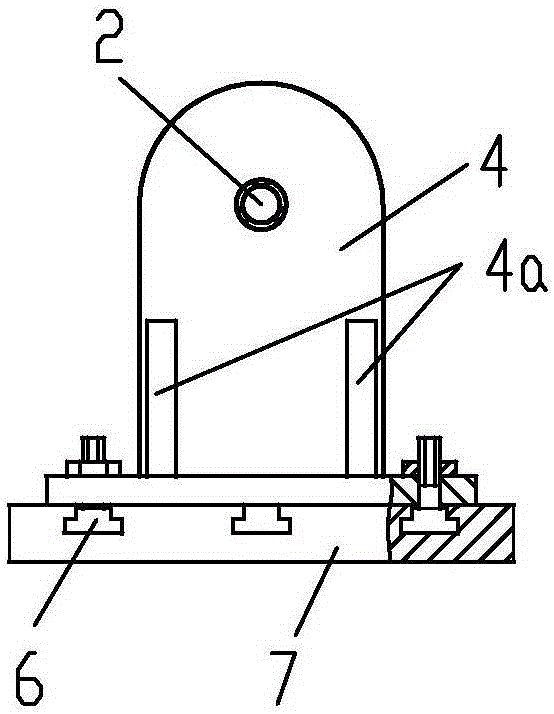

[0035] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a dynamic characteristic testing device for a dynamic vibration absorber of a vehicle transmission system, comprising a round rod-shaped circular mandrel 2 for installing a dynamic shock absorber 1; the circular mandrel 2 passes through the three jaws of the three-jaw chuck 3 at both ends 3a is fixed in a horizontal state by means of clamping, and the two three-jaw chucks 3 are respectively fixedly connected to the vertical sides of the two support bases 4, and the two support bases 4 are fixedly connected to the workbench 7 by the horizontal side through four bolts 6 and nuts. Above, the workbench 7 is provided with a plurality of T-shaped slots that run through the side of the workbench 7 in a criss-cross pattern; the bolts 6 are in a matching T-shaped head structure that slides with the T-shaped slots. Specifically, the T-shaped head of the bolt 6 has a two-stage stepped structu...

Embodiment 2

[0039] Example 2, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a method for testing the dynamic characteristics of a dynamic vibration absorber of a vehicle transmission system, the method utilizes the test system formed by the test device of embodiment 1, data acquisition and analysis system to test, comprising the following steps:

[0040] S1. The installation of the dynamic vibration absorber 1 includes fixing the dynamic vibration absorber 1 to be tested on the circular mandrel 2 according to the actual installation method on the vehicle; passing the circular mandrel 2 through the two three-jaw chucks 3 at both ends respectively The positioning of the three jaws 3a; adjust the position of the support seat 4 so that the three-jaw chuck 3 is in the axial setting position of the circular mandrel 2, and form a support for the circular mandrel 2 and the support by the three-jaw chuck 3 and the bolt 6 respectively. Fixing of seat 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com