Ultrasound feature imaging detecting device for detecting stirring friction weld detect of airplane oil tank

A technology of aircraft fuel tank and characteristic imaging, which is applied in the direction of analyzing solids by using sound waves/ultrasonic waves/infrasonic waves, to achieve the effects of improving quantitative, rapid evaluation, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

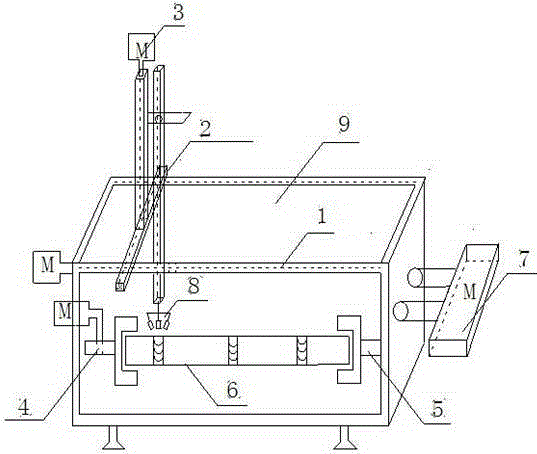

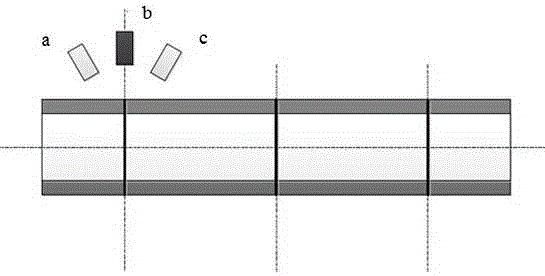

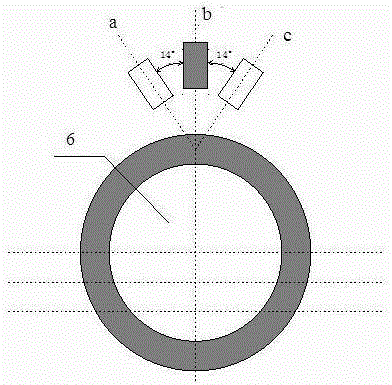

[0039] Such as figure 1 As shown, the ultrasonic feature imaging detection device includes a water tank (9), a gasoline fuel tank movement system, a detection scanning system and an ultrasonic imaging system. The gasoline fuel tank movement system consists of a water circulation filter system (7) connected to the water tank (9), The positioning pin I (4) and positioning pin II (5) are symmetrically installed on the two side walls of the water tank (9). The positioning pin I (4) is driven by a servo motor; the detection and scanning system includes X-axis (1) on (9), Y-axis (2) installed on X-axis (1), Z-axis (3) installed on Y-axis (2), detection probe bracket (8) installed at the end of Z-axis ), three detection probes with different incident angles are installed on the detection probe bracket, and the X-axis (1), Y-axis (2), and Z-axis (3) are respectively driven by corresponding servo motors; the ultrasonic imaging system includes connecting 3 3 ultrasonic analyzers for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com