Control method and system for daylight hothouse roller blind machine based on light and temperature coupling

A solar greenhouse and control method technology, applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve problems such as long working hours, poor safety, accidents involving dead people, etc., to achieve unified management and control, reliable High reliability and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

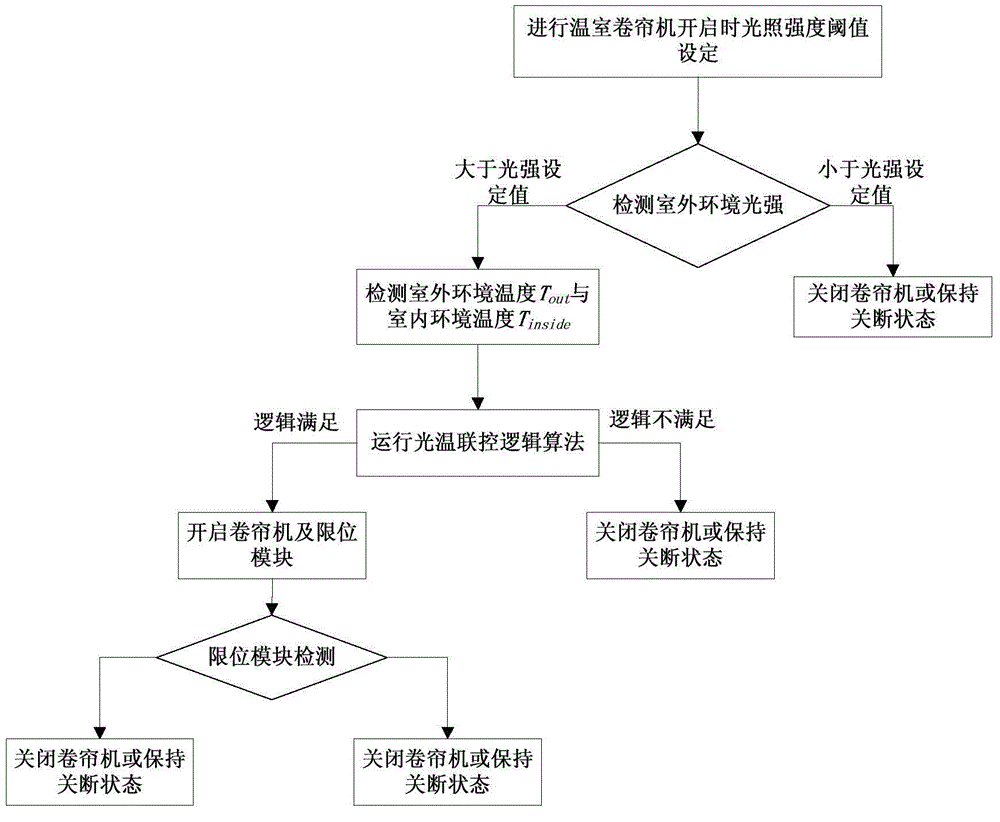

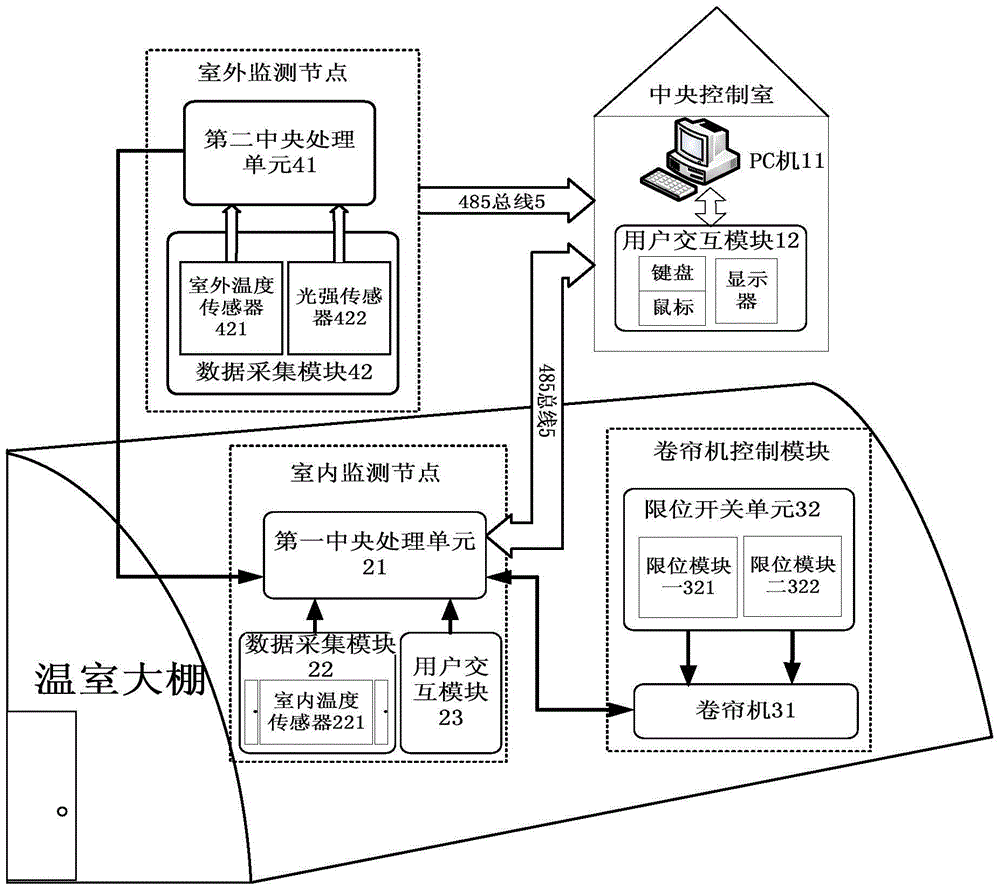

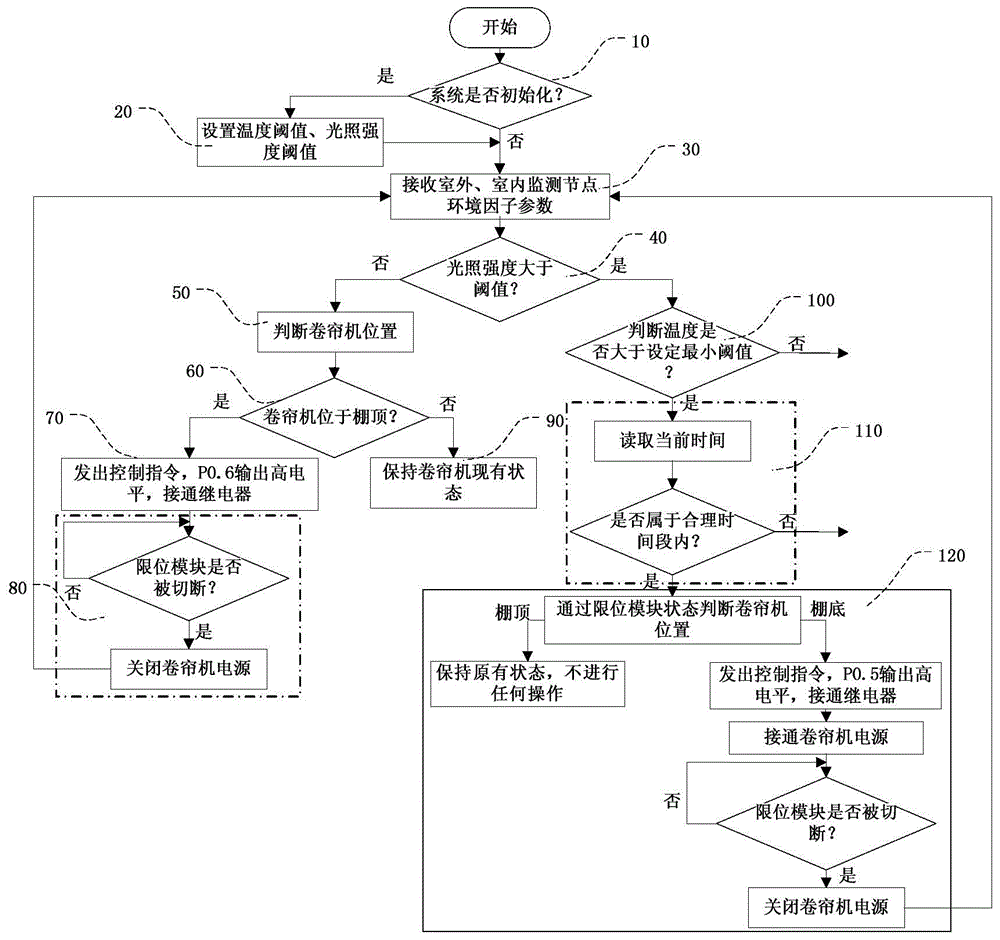

[0041] Such as figure 1As shown, the present invention is based on a light-temperature coupling solar greenhouse rolling machine control method. According to the light intensity required for the plant growth stage, the light intensity threshold is set; the real-time light intensity outside the greenhouse is detected and judged by comparing with the threshold. If the light intensity is required, it is judged that the roller shutter can be opened; if the ambient light intensity is less than the set light intensity threshold, it is judged that the roller shutter is closed or the roller shutter is not opened to keep the original state. After it is judged that the shutter machine can be turned on, the indoor real-time temperature is detected through the monitoring node in the greenhouse, and the outdoor temperature is detected in real time through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com