Application of p-doped sic nanowires in field emission cathode materials

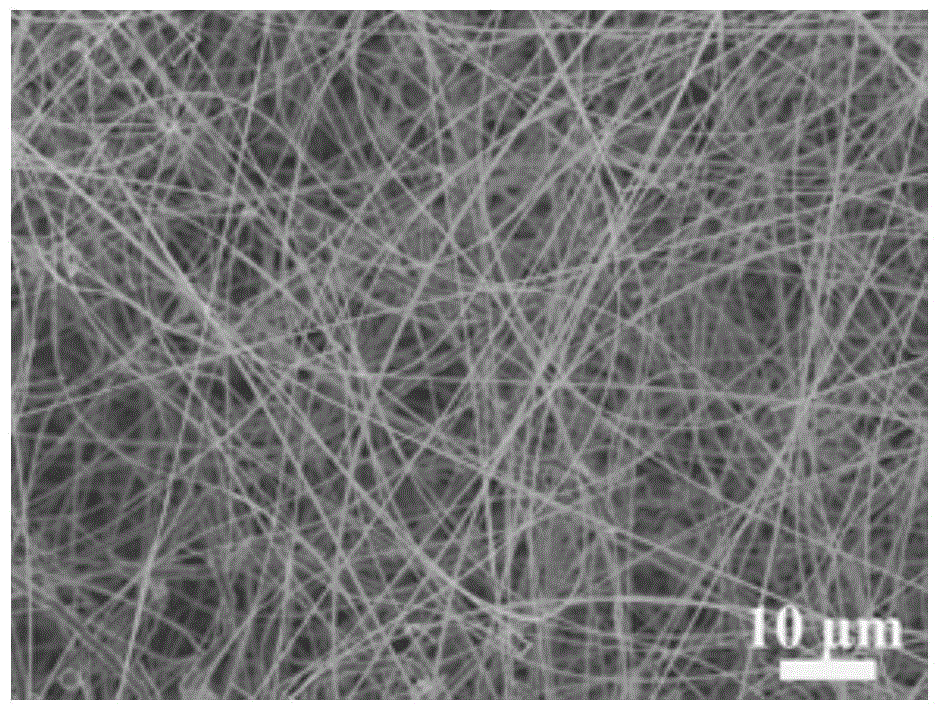

A field emission cathode and emission cathode technology, applied in the field of nanowire materials, can solve the problems of cutting-edge technology difficulty, preparation difficulty, complex process, etc., and achieve the effects of good cost controllability, stable performance, and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Choose polysilazane, in N 2 Under the protection of the atmosphere, heat-preserve at 260° C. for 30 minutes for thermal cross-linking and curing, put the solidified SiCN solid into a nylon resin ball mill jar, and ball mill and pulverize it into powder.

[0056] Cut the carbon paper 5×5cm (length×width), in 0.05mol / L Co(NO 3 ) 3 After soaking in ethanol solution and ultrasonic treatment, take it out and put it in the air environment to dry naturally.

[0057] Weigh 0.3g of polysilazane powder and 0.06g of FePO 4 The powders were mixed and placed at the bottom of a graphite crucible, and the sonicated carbon paper was placed on top of the crucible.

[0058] Put the graphite crucible and carbon paper together in the graphite resistance atmosphere sintering furnace, and the atmosphere furnace is first evacuated to 10 -4 Pa, then fill with high-purity Ar gas (purity is 99.99%), until the pressure is an atmospheric pressure (0.11Mpa), after that the pressure is constant,...

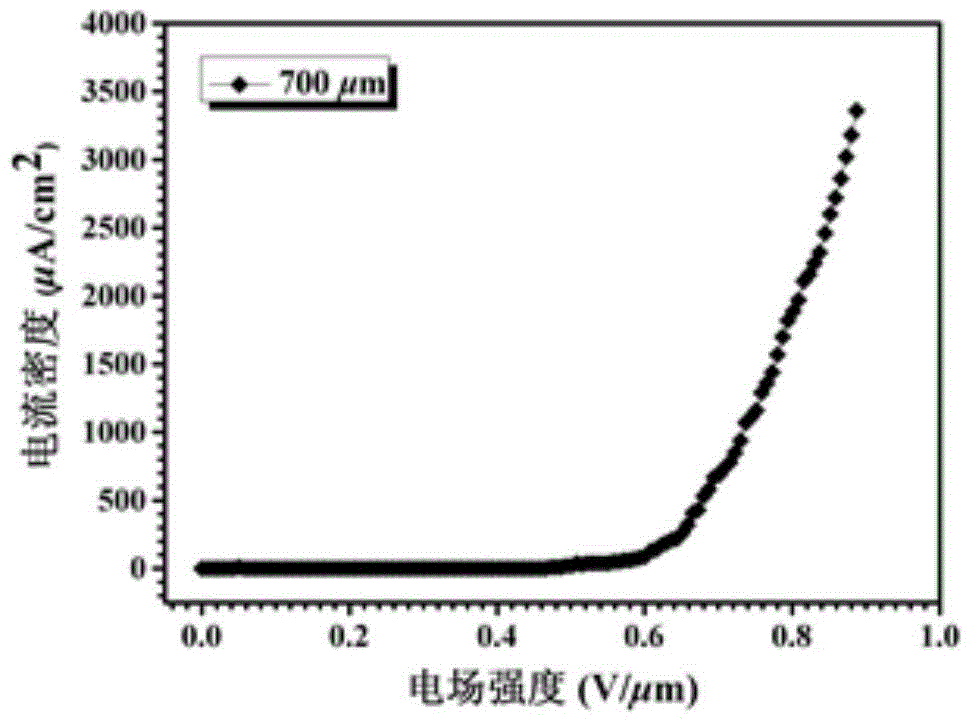

Embodiment 2

[0060] The only difference from Example 1 is that the pyrolysis temperature is different, and the pyrolysis temperature in Example 2 is 1400°C.

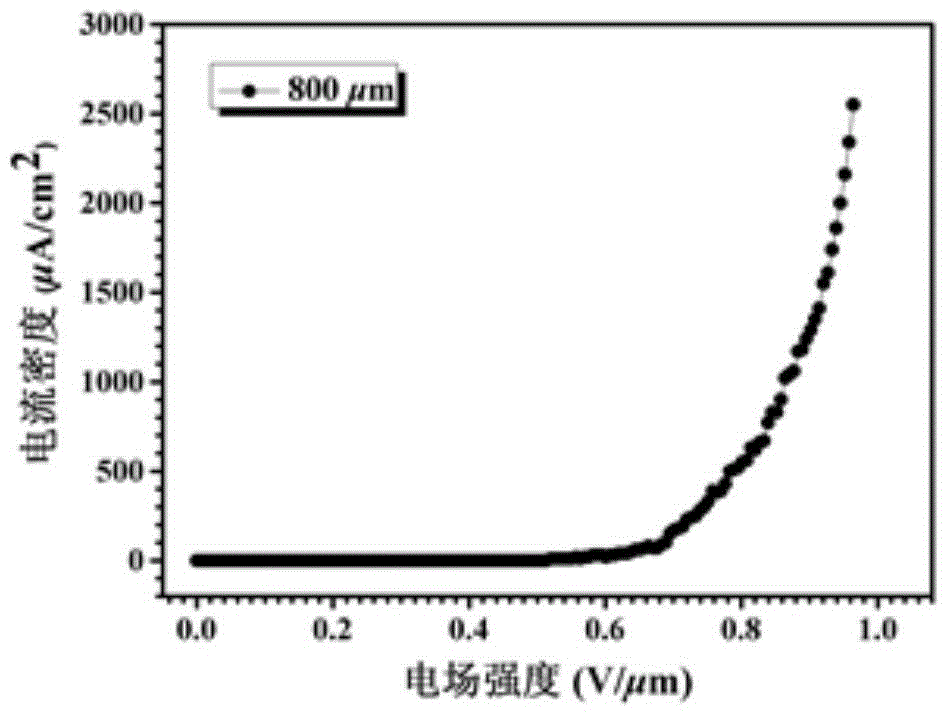

Embodiment 3

[0062] The only difference from Example 1 is that the pyrolysis temperature is different, and the pyrolysis temperature in Example 3 is 1350°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com