Antibacterial glass

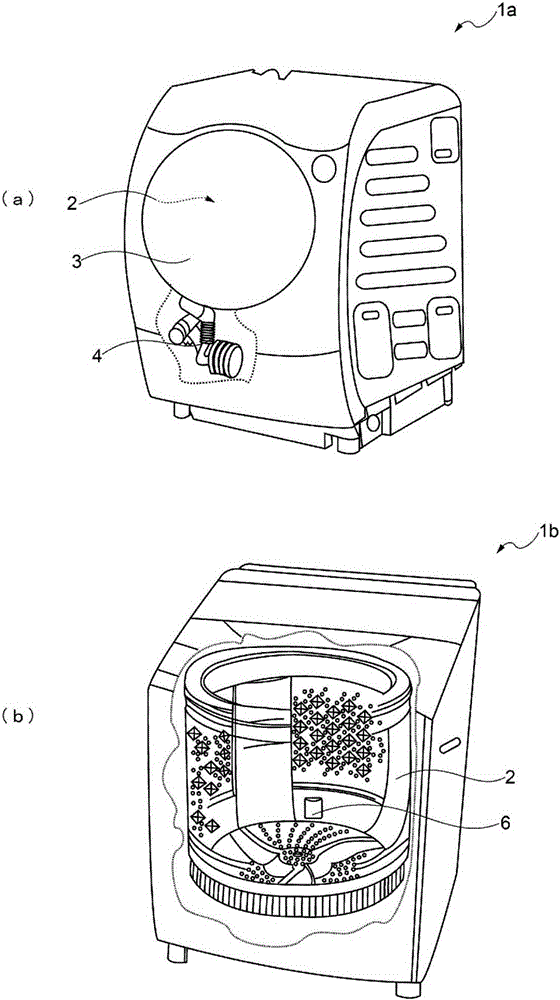

A kind of antibacterial glass, weight technology, applied in the direction of sterilization/microdynamic water/sewage treatment, biocide, animal repellent, etc., can solve the problems of accelerated dissolution speed, coloring of washed objects, difficult silver ion dissolution, etc. , to achieve the effect of inhibiting cladosporium buds and inhibiting coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0229] 1. Fabrication of antibacterial glass

[0230] (1) Melting process

[0231] As an antibacterial glass composition, the glass raw material of the composition shown in Table 1 was stirred with the universal mixer at the rotation speed of 250 rpm, and 30 minutes until it mixed uniformly.

[0232] Subsequently, using a glass melting furnace, the glass raw materials were heated at 1280° C. for 3.5 hours to produce molten glass.

[0233] (2) Molding process

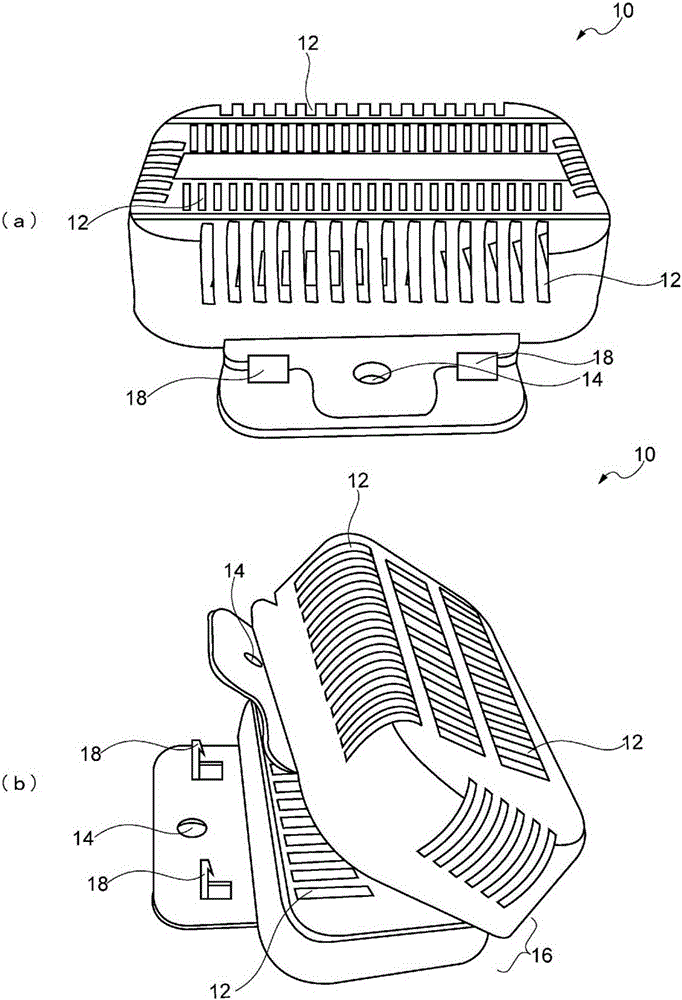

[0234] Such as Figure 14 As shown in (a) to 14(b), the molten glass 42 taken out from the glass melting furnace is introduced into the forming device 40, and formed as follows: Figure 11 Tablet-shaped antibacterial glass 22 shown (maximum diameter: 10 mm, surface area each: 2.5 cm 2 ).

[0235] (3) Surface grinding process

[0236] 500 g of the obtained tablet-shaped antibacterial glass is dropped into a vibrating ball mill that does not use a medium. Subsequently, 500 g of isopropanol was added, and in this sta...

Embodiment 2

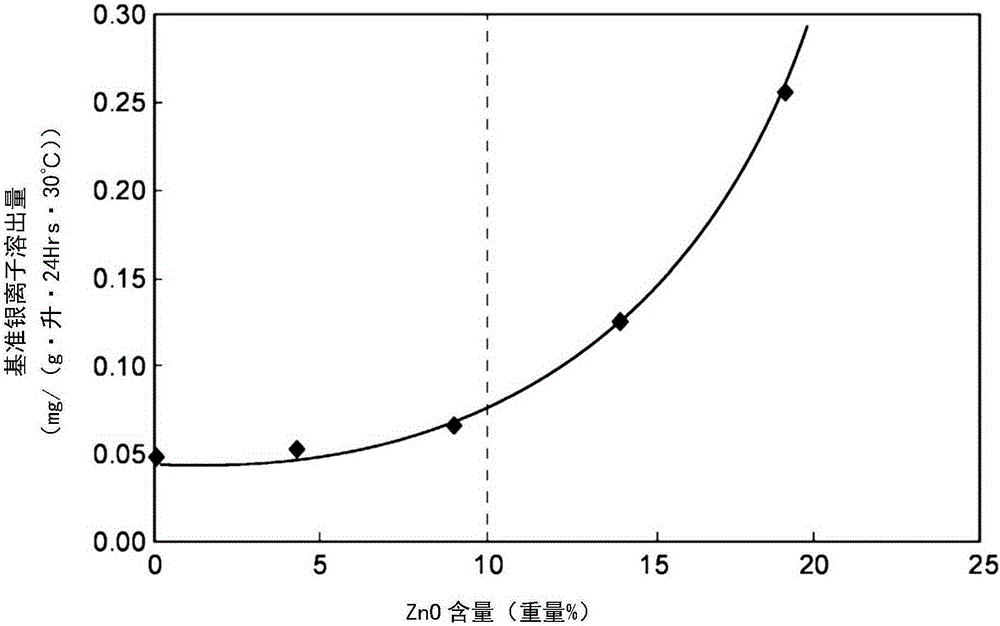

[0278] In embodiment 2, antibacterial glass composition, as shown in table 1, Ag 2 While the content of O and CoO is kept as it is, the content of ZnO is reduced to 4.05% by weight, and for other components, the proportion is maintained, and the corresponding increase is due to the reduction of the content of ZnO. In addition, in the same manner as in Example 1, a Antibacterial glass and evaluation. Table 1 shows the obtained results.

Embodiment 3

[0280] In embodiment 3, antibacterial glass composition, as shown in table 1, Ag 2 While the content of O and CoO is kept as it is, the content of ZnO is reduced to 0% by weight, and for other components, the proportion is maintained, and the corresponding increase is due to the reduction of the content of ZnO. In addition, in the same manner as in Example 1, a Antibacterial glass and evaluation. Table 1 shows the obtained results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com