Mechanoluminescent material and use applications thereof, raw material composition for mechanoluminescent material, and method for producing mechanoluminescent material

A technology of raw material composition and stress luminescence, which is applied in the direction of luminescent materials, chemical instruments and methods, fluorescence, etc., can solve the problems that the luminous brightness has not yet been obtained, and achieve the effect of high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

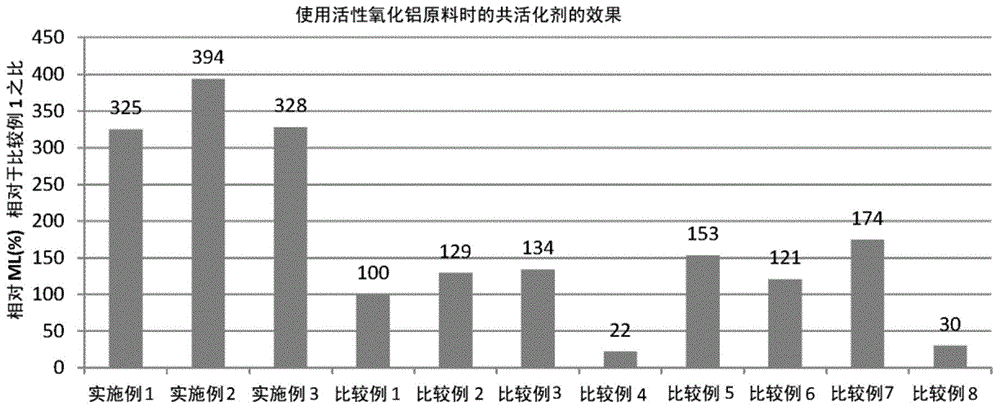

[0165] Embodiment 1 (using activated alumina as a raw material, using neodymium as a stress luminescent material as a co-activator)

[0166] Strontium carbonate (SW-K manufactured by Sakai Chemical Industry Co., Ltd., 23.50 g), europium oxide (manufactured by Shin-Etsu Chemical Co., Ltd., 0.16 g), neodymium oxide (manufactured by Wako Pure Chemical Industries, Ltd., reagent, 0.06 g), Alumina (manufactured by Iwatani Chemical Industry Co., Ltd., activated alumina RG-40 (mixture of θ alumina and η alumina, α alumina content: 8 mol%), 18.04 g) was put into water (90 mL). Thereafter, using alumina balls with a diameter of 3 mm (manufactured by Nikkato Co., Ltd., SSA-999W, 190 g) as a grinding medium, dispersion, grinding, and mixing were performed using a planetary ball mill to obtain a slurry. The resulting slurry was evaporated to dryness at 130°C. The obtained solid was pulverized with a mortar to obtain a powdery raw material composition for a stress light-emitting material. ...

Embodiment 2

[0167] Example 2 (using activated alumina as a raw material and using dysprosium as a stress-luminescent material as a co-activator)

[0168] Strontium carbonate (SW-K manufactured by Sakai Chemical Industry Co., Ltd., 23.50 g), europium oxide (manufactured by Shin-Etsu Chemical Co., Ltd., 0.16 g), dysprosium acetate tetrahydrate (manufactured by Wako Pure Chemical Industries, Ltd., reagent, 0.15 g) were weighed. g) Alumina (manufactured by Iwatani Chemical Industry Co., Ltd., activated alumina, RG-40, 18.03 g) was thrown into water (90 mL). Thereafter, in the same manner as in Example 1, the target stress luminescent material was obtained in the form of powder.

Embodiment 3

[0169] Example 3 (using activated alumina as a raw material and using holmium as a stress-luminescent material as a co-activator)

[0170] Strontium carbonate (SW-K manufactured by Sakai Chemical Industry Co., Ltd., 23.50 g), europium oxide (manufactured by Shin-Etsu Chemical Co., Ltd., 0.16 g), holmium oxide (manufactured by Wako Pure Chemical Industries, Ltd., reagent, 0.07 g), Alumina (manufactured by Iwatani Chemical Industry Co., Ltd., activated alumina, RG-40, 18.03 g) was thrown into water (90 mL). Thereafter, in the same manner as in Example 1, the target stress luminescent material was obtained in the form of powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com