Spray-type plant in-vitro culturing system and method

An in vitro culture and spray technology, applied in the biological field, can solve the problems of not being able to meet the needs of large batches, be easily restricted by natural conditions, and have a low reproductive success rate, and achieve the use of light conditions and greenhouse space to promote plant elongation and The effect of sprout formation and high reproduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

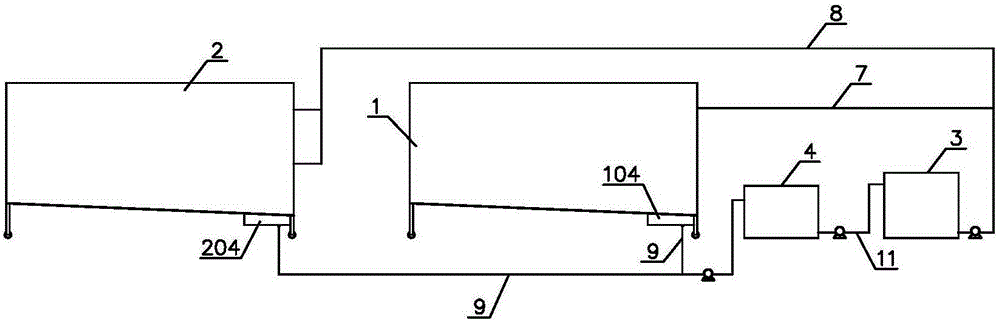

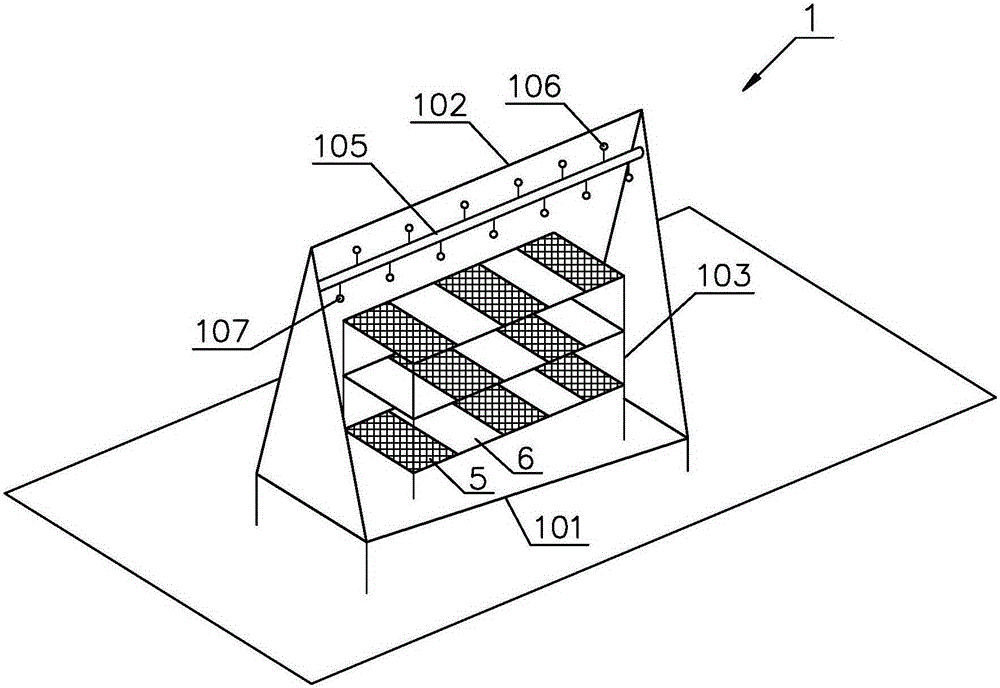

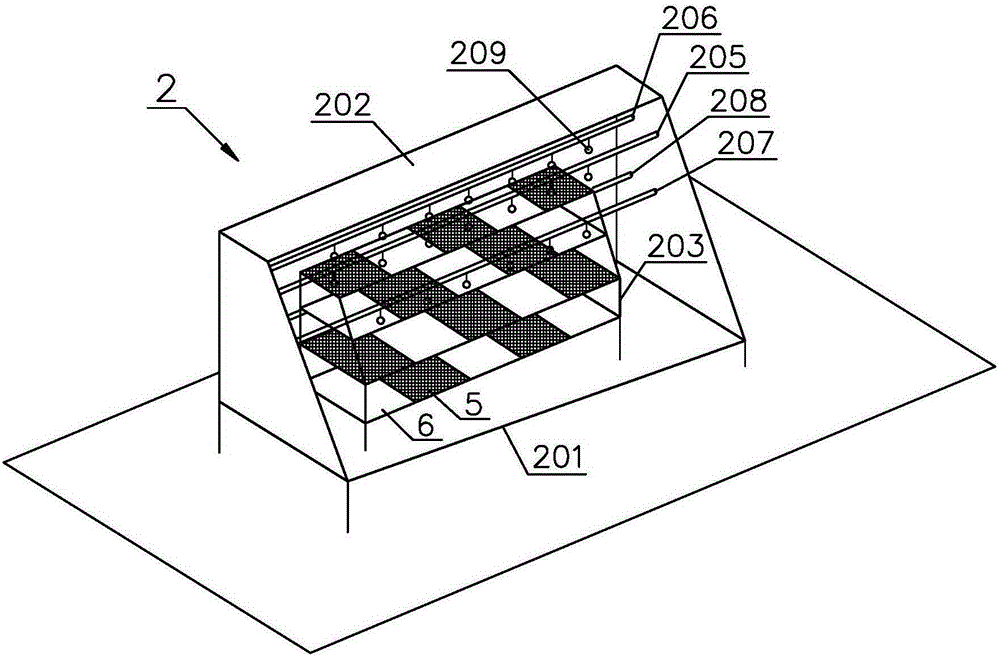

[0040] like Figure 1 ~ Figure 3 Shown, a kind of spray type plant in vitro culture system comprises the steps:

[0041] The spray plant reactor includes the first fog cultivation box 1, the second fog cultivation box 2, the water tank 3, the recovery water tank 4 and the control system:

[0042] The first aeroponic box 1 comprises a rectangular first bottom plate 101 and a top horizontal support 102, the left end of the top horizontal support 102 is connected to the left two ends of the first bottom plate 101 respectively by two first side supports, the top horizontal support 102 The right end is respectively connected to the right two ends of the first bottom plate 101 by two first side supports; the inside of the first aeroponic box 1 includes the first cultivation frame 103; 10~15°, the lower side of the first bottom plate 101 is provided with a first water collection tank 104; the upper part of the first culture frame 103 is horizontally provided with a first water guide p...

Embodiment 2

[0057] A kind of culture method that adopts spray type plant in vitro culture system of the present invention to carry out, comprises the steps:

[0058] The explants are cleaned and placed on the sponge 6 in the first mist culture box 1 and the second mist culture box 2 of the spray type plant in vitro culture system for cultivation, and the base of the explants will germinate in 13-15 days Adventitious buds emerge, and small plants can be obtained in 45 days, and the culture solution is sprayed on the explants by spraying in the cultivation process.

Embodiment 3

[0060] The explants are yams. Clean the yams and cut them into 1-2cm thick discs, and then divide the discs into 4 pieces as explants and place them neatly in the first fog culture box 1 and the second fog culture box 2. Cultivate on the storage sponge 6 in the medium, the base of the explant can germinate adventitious buds in 13-15 days, and can obtain the yam plantlet in 45 days;

[0061] The cultivation process adopts spray treatment, including 4 stages:

[0062] The first stage: the time is from the first day to the sixth day. There are 6 time points at 0 o'clock, 4 o'clock, 7 o'clock, 11 o'clock, 15 o'clock and 20 o'clock every day, and a spraying treatment is carried out at each time point , the culture medium used is MS+0.15mg / LGA3+1.6mg / L6-BA+1200mg / L carbendazim;

[0063] The second stage: the time is from the 7th day to the 20th day. There are 5 time points at 0 o'clock, 5 o'clock, 9 o'clock, 13 o'clock and 18 o'clock every day, and two spray treatments are carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com